Embossed aluminum sheets made from alloys 1100, 1060, 3003, and 3004 are widely used where decorative appearance, slip resistance, and improved rigidity are required without significantly increasing weight.

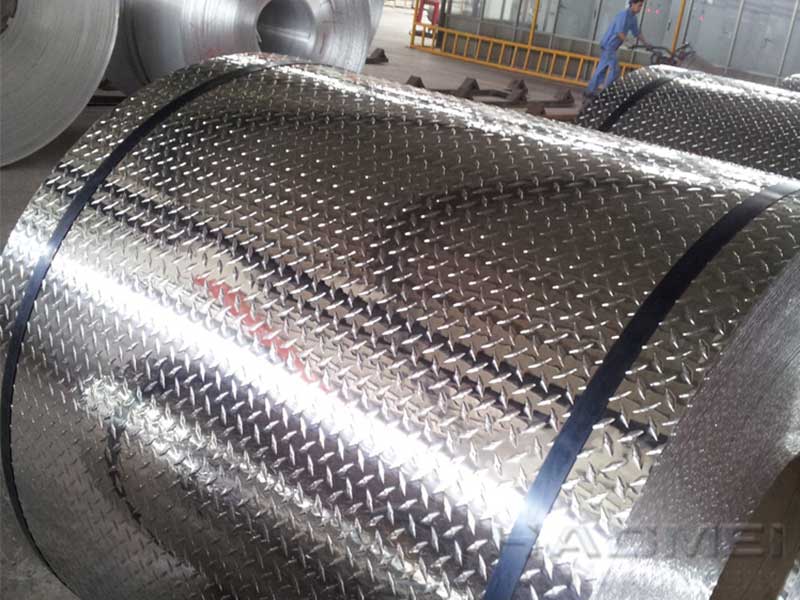

Embossed aluminum sheet (also called pattern aluminum sheet or stucco/checkered plate) is produced by rolling base aluminum coil through patterned rollers, forming a permanent raised or indented texture.

Typical patterns include:

- Stucco / orange peel

- Diamond

- Five-bar / one-bar antiskid

- Hammered / leather grain (special order)

The alloys 1100, 1060, 3003, 3004 cover a wide range of needs:

- 1100, 1060: High-purity aluminum, excellent formability and corrosion resistance; economical.

- 3003, 3004: Aluminum-manganese alloys, higher strength and better overall performance.

2. Product Features

2.1 Main Advantages

Lightweight with high stiffness

The embossed pattern increases stiffness and resistance to denting at the same thickness.Excellent corrosion resistance

Particularly in indoor and mildly corrosive outdoor environments, suitable for building, cold storage, and food-related uses.Good formability and workability

Easy to shear, bend, roll form, rivet, and weld; suitable for complex panels and covers.Decorative surface

The textured pattern diffuses light, masking minor scratches and fingerprints, keeping a clean and attractive appearance.Slip-resistance

Embossed patterns improve friction, ideal for floors, steps, walkways, and truck beds.Good reflectivity and thermal performance

Aluminum’s natural reflectivity, combined with patterning, makes it suitable for insulation jacketing and HVAC systems.

3. Typical Chemical Composition

The following table shows typical chemical composition ranges (wt%) for the four alloys:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.10 | ≥99.6 |

| 1100 | ≤0.95 (Si+Fe) | — | 0.05–0.20 | ≤0.05 | — | ≤0.10 | ≤0.05 | ≤0.05 | ≤0.15 | ≥99.0 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | — | ≤0.10 | — | ≤0.05 | ≤0.15 | Balance |

| 3004 | ≤0.30 | ≤0.70 | ≤0.25 | 1.0–1.5 | 0.8–1.3 | ≤0.25 | ≤0.15 | ≤0.05 | ≤0.15 | Balance |

Note: Actual composition may vary slightly by standard (GB/T, ASTM, EN) and producer.

4. Mechanical Properties & Performance

4.1 Mechanical Properties (Flat Sheet Before Embossing)

Typical room-temperature mechanical properties in common tempers:

| Alloy | Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Relative Strength Level |

|---|---|---|---|---|---|

| 1060 | O | 60–95 | 20–30 | 25–35 | Low |

| 1060 | H14 | 95–125 | 40–80 | 15–25 | Low–medium |

| 1100 | H14 | 110–145 | 85–120 | 10–20 | Low–medium |

| 3003 | H14 | 140–180 | 115–160 | 8–20 | Medium |

| 3003 | H24 | 150–190 | 120–170 | 8–18 | Medium |

| 3004 | H24 | 190–250 | 150–215 | 7–15 | Medium–high |

Embossing slightly increases apparent stiffness but can reduce ductility in the deformed surface layer. For bending and deep drawing, select softer tempers (O, H12, H14) and allow for texture orientation.

4.2 Physical & Surface Performance

| Property | Typical Value / Behavior |

|---|---|

| Density | ≈ 2.70 g/cm³ |

| Melting Range | 1060/1100: ~645–657°C; 3003/3004: ~635–655°C |

| Thermal Conductivity | 160–220 W/(m·K), high heat transfer |

| Electrical Conductivity | 1060/1100: ~55–60% IACS; 3003/3004: slightly lower |

| Corrosion Resistance | Very good in atmospheric and many mild industrial environments |

| Surface Finish (mill finish) | Natural silver-white, can be anodized or painted |

| Slip Resistance | Higher than flat sheet due to raised pattern |

| Cleanability | Pattern hides scratches; smooth peaks allow wiping |

5. Technical Specifications

5.1 Standard Dimensions

Below are typical available ranges; specific sizes can be customized.

| Parameter | Common Range / Option |

|---|---|

| Thickness | 0.3–1.5 mm (insulation, decorative) |

| 1.5–6.0 mm (flooring, steps, truck bed, ramps) | |

| Width | 500–1500 mm typical; up to 2000 mm on request |

| Length | 500–6000 mm for sheets; coils supplied on request |

| Pattern Types | Stucco, orange peel, diamond, five-bar, one-bar, special |

| Temper | O, H12, H14, H16, H18, H22, H24 (depending on alloy) |

| Surface | Mill finish, anodized, color-coated (PVDF/PE) optional |

| Edge | Mill edge, slit edge |

5.2 Dimensional Tolerances (Reference)

Tolerances vary by standard and thickness, but typical values:

| Item | Typical Tolerance Range |

|---|---|

| Thickness | ±0.02–±0.10 mm (depending on nominal t) |

| Width | ±2.0 mm |

| Length | ±3.0–±5.0 mm |

| Diagonal | ≤0.5–1.0% of length |

| Pattern Height | About 0.20–1.00 mm (pattern dependent) |

6. Alloy Selection Guide

Choosing between 1100, 1060, 3003, 3004 depends on the balance of strength, formability, and environment.

| Alloy | Advantages | Limitations | Typical Uses |

|---|---|---|---|

| 1060 | Highest purity, excellent ductility, best electrical conductivity, low cost | Lowest strength | Decorative panels, insulation jacketing, signage, non-structural covers |

| 1100 | Good corrosion resistance, better strength than 1060, good formability | Not heat-treatable, moderate strength | Building decoration, reflectors, interior trim, HVAC cladding |

| 3003 | Higher strength than 1xxx, very good corrosion resistance, good workability | Slightly higher cost than 1xxx | Cold rooms, truck body interior, toolboxes, stair treads (light duty) |

| 3004 | Even higher strength, good formability, better load capability | Slightly lower formability than 1060 | Floors, heavy-duty steps, ramps, mechanical covers, transport flooring |

7. Major Application Areas

7.1 Construction & Architecture

- Wall and ceiling decorative panels

- Elevator and corridor wall protection plates

- Stair treads, platforms, walkways, and ramps

- Door kick plates and corner guards

Benefits:

- Attractive metallic appearance

- Safe, anti-slip surfaces

- Easy cutting and on-site installation

7.2 Refrigeration, HVAC & Insulation

- Cold room wall and ceiling lining (3003/3004 recommended for strength)

- Ducting and piping insulation jacketing (1060/1100)

- Outdoor equipment enclosures and housings

Benefits:

- High corrosion resistance in humid, low-temperature environments

- Good thermal conductivity for stable insulation performance

- Embossed pattern hides dents and handling marks

7.3 Transportation & Vehicle Use

- Truck and trailer floors, side panels, toolboxes

- Bus and van interior panels, step plates

- Railway carriage interior decoration

Benefits:

- Weight reduction compared with steel plates

- Slip-resistant surface for safer access

- Good vibration and fatigue resistance (especially 3003/3004)

7.4 Industrial & Commercial Facilities

- Machine guards and equipment covers

- Anti-slip working platforms and catwalks

- Shelving, cabinets, and storage boxes

Benefits:

- Long service life with low maintenance

- Easy processing for customized shapes

- Clean, professional aesthetic

8. Processing & Fabrication Notes

| Operation | Suitability & Recommendations |

|---|---|

| Cutting | Shearing, sawing, laser, and plasma are all feasible |

| Bending | Bend across pattern direction when possible; use larger radii to avoid cracking on raised surfaces |

| Forming | Deep drawing easier with 1060/1100 O temper; moderate forming with 3003/3004 H14/H24 |

| Welding | TIG/MIG welding with proper filler (e.g., 1100, 4043) is workable |

| Surface Treatment | Anodizing improves corrosion & appearance; painting/coil coating available |

| Cleaning | Neutral detergents preferred; avoid strong alkali that attacks aluminum |

Embossed aluminum sheet in 1100, 1060, 3003, and 3004 offers:

- Optimized balance of weight, strength, and appearance

- High corrosion resistance for indoor and many outdoor environments

- Enhanced safety thanks to slip-resistant patterns

- Flexible processing for cutting, bending, and finishing

- Cost-effective life cycle due to low maintenance and long service life

For decorative cladding and insulation, 1060 / 1100 are economical and easy to form. For higher mechanical requirements (floors, platforms, transport flooring), 3003 / 3004 provide the necessary strength and durability.

By selecting the right alloy, thickness, and pattern, you can tailor embossed aluminum sheets precisely to your performance and budget needs.