High-Performance Coil & Strip Solutions for Architectural and Industrial Panels

Aluminum strip panel using 5005 and 5052 alloys delivers excellent corrosion resistance, medium-to-high strength, and superior surface quality for architectural façades, curtain walls, interior cladding, signage, and industrial panel systems. These alloys offer stable anodizing performance, good formability, and consistent flatness, making them ideal for coil-coated, anodized, or PVDF-painted panel applications that demand both aesthetics and durability.

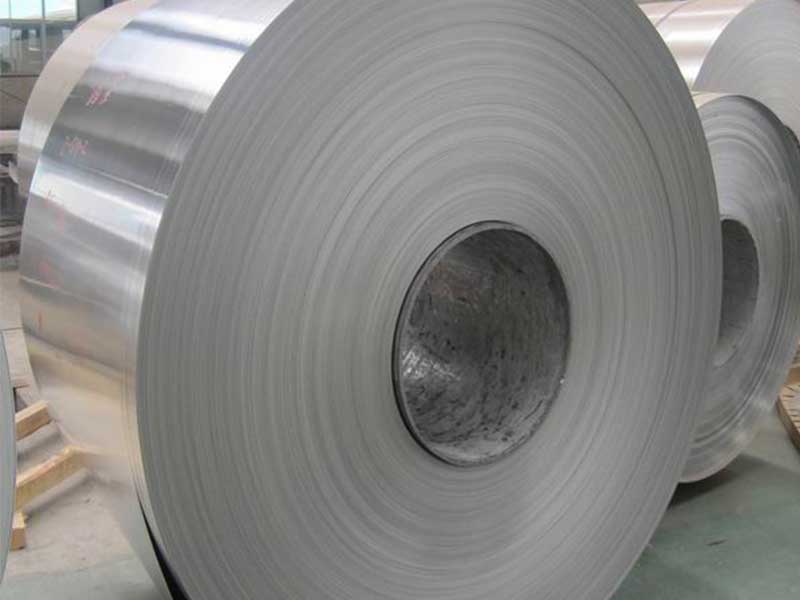

Aluminum strip panels made from 5005 and 5052 alloys are widely used as base materials for composite panels, honeycomb panels, and solid sheet façades. Supplied in coil or precision-cut strip form, they offer:

- Stable mechanical properties across coil length

- Excellent corrosion resistance in outdoor and marine environments

- Consistent surface for anodizing or high-end coating systems

5005 is favored for architectural anodized finishes due to its color consistency, while 5052 is chosen where higher strength and better seawater resistance are required.

Features of 5005 / 5052 Aluminum Strip Panels

Performance Highlights

| Feature | 5005 Alloy | 5052 Alloy |

|---|

| Strength level | Low–medium | Medium–high |

| Corrosion resistance | Very good (atmospheric) | Excellent (atmospheric and marine) |

| Anodizing quality | Very good, color-uniform façade applications | Good, used where strength more critical |

| Formability & bending | Excellent cold formability | Very good, suitable for moderate-to-deep forming |

| Weldability | Good with common processes | Excellent, especially TIG/MIG |

| Surface quality | Fine, uniform grain for decorative uses | Clean, robust surface for coated panels |

| Weight reduction vs. steel | ~65% lighter than mild steel | ~65% lighter than mild steel |

| Service life in exterior use | Long-term with proper coating/anodizing | Long-term, even in coastal or industrial zones |

Typical Panel & Coil Supply Range

| Parameter | Range / Option |

|---|

| Alloy | 5005, 5052 |

| Temper | H14, H16, H18, H24, H32, O (soft) |

| Thickness range | 0.20 – 4.0 mm (typical façade: 0.5 – 3.0 mm) |

| Width range | 20 – 1600 mm (customized on request) |

| Coil inner diameter | 150 / 305 / 508 mm |

| Coil outer diameter | Up to 1800 mm |

| Coil weight | 500 – 6000 kg per coil |

| Surface finish | Mill finish, brushed, embossed, coil-coated, anodized |

| Protective film | Single or double-sided PE film |

Chemical Composition

Aluminum Alloy 5005 Chemical Composition (Typical, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Others (total) | Al |

|---|

| % | ≤0.30 | ≤0.70 | ≤0.20 | ≤0.20 | 0.50–1.1 | – | ≤0.25 | ≤0.20 | ≤0.05 | ≤0.15 | Balance |

Aluminum Alloy 5052 Chemical Composition (Typical, wt%)

| Element | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (each) | Others (total) | Al |

|---|

| % | ≤0.25 | ≤0.40 | ≤0.10 | 0.05–0.20 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | – | ≤0.05 | ≤0.15 | Balance |

Mechanical & Technical Specifications

Typical Mechanical Properties

Values are indicative; actual data depend on thickness and temper.

5005 Aluminum Strip Panel

| Temper | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) | Typical Use Case |

|---|

| O | 45 – 75 | 110 – 145 | 18 – 25 | Deep drawing, complex bends, formed covers |

| H14 | 80 – 120 | 145 – 185 | 8 – 16 | Coil-coated façade, interior wall panels |

| H16 | 110 – 150 | 165 – 205 | 6 – 14 | Stiff panels, trays, display structures |

| H18 | 130 – 170 | 175 – 215 | 4 – 10 | Very flat strips, signage, nameplates |

5052 Aluminum Strip Panel

| Temper | Yield Strength Rp0.2 (MPa) | Tensile Strength Rm (MPa) | Elongation A50 (%) | Typical Use Case |

|---|

| O | 65 – 95 | 170 – 215 | 18 – 28 | Deep-drawn components, formed housings |

| H32 | 130 – 180 | 210 – 260 | 8 – 14 | Structural panels, marine cladding |

| H34 | 150 – 200 | 220 – 270 | 6 – 12 | High-rigidity strips, transport panels |

| H36 | 170 – 220 | 230 – 280 | 5 – 10 | Heavy-duty exterior and trailer panels |

Dimensional & Flatness Control

| Property | Typical Value / Control Level |

|---|

| Thickness tolerance | As per EN/ASTM, commonly ±0.02–0.05 mm (depending on gauge) |

| Width tolerance | ±0.5 – ±1.0 mm |

| Coil shape | Controlled crown and edge wave for smooth unwinding |

| Flatness (wave height) | Optimized for panel lamination and composite lines |

| Edge type | Mill edge or slit edge, deburred on request |

Surface Options & Coating Systems

Aluminum strip panels using 5005 and 5052 can be delivered in several surface conditions depending on the end application.

Surface Condition Comparison

| Surface Type | Description | Typical Use |

|---|

| Mill finish | As-rolled, clean, light rolling pattern | Structural back sheets, non-visible components |

| Brushed / satin | Mechanically brushed for decorative texture | Interior panels, display systems, furniture |

| Embossed | Stucco, diamond, or custom patterns | Anti-slip panels, ceiling panels, insulation jacketing |

| Anodized (5005 focus) | Controlled anodic layer, stable color | High-end façades, curtain walls, exterior signage |

| Coil-coated (PE/HDPE) | Polyester-based coatings, good cost-performance | Interior cladding, advertising panels |

| PVDF / FEVE coated | Premium weathering resistance, gloss retention | Architectural façades, coastal and high-UV zones |

Applications

Architectural & Building Envelope

| Application Area | Why 5005 / 5052 Works Well |

|---|

| Curtain wall panels | Lightweight, strong, and compatible with PVDF system |

| Solid façade cladding | Good flatness and thermal expansion compatibility |

| Composite panels (ACM base) | Clean coil surface, stable coating performance |

| Interior wall & ceiling panels | Excellent formability, various textures and colors |

| Column covers & soffits | Easy bending and rolling, smooth surface |

5005 strip is often selected when an anodized, metallic look must match across large building surfaces. 5052 is preferred for canopies, balcony panels, and areas with higher wind loads or structural demands.

Transportation & Industrial Panels

| Segment | Typical Use of 5005 / 5052 Strip Panels |

|---|

| Truck & trailer bodies | Side walls, door panels, roof strips |

| Bus & rail vehicle interiors | Ceiling and side panels, luggage rack cladding |

| Marine & offshore structures | Cabin panels, partition walls, protective liners |

| HVAC & ducting | Lightweight, corrosion-resistant duct panels |

| Machinery enclosures | Access doors, covers, soundproof panels |

5052’s higher magnesium content provides outstanding resistance to marine atmospheres and road de-icing salts, making it a frequent choice for exterior transport and marine panel systems.

Signage & Display

| Usage | Benefit of 5005 / 5052 |

|---|

| Outdoor signs & billboards | Durable, UV-resistant when coated, good rigidity |

| Corporate identity panels | Color-stable anodizing (5005) or PVDF coating |

| Wayfinding & interior signage | Clean, flat surfaces for precise printing |

Temper Selection Guidelines

Choosing the right temper is critical for performance and processing efficiency.

| Requirement / Process | Recommended Alloy & Temper | Reason |

|---|

| Deep forming, tight radii | 5005-O / 5052-O | Maximum ductility and low cracking risk |

| Coil coating + moderate forming | 5005-H14 / H16 | Good balance of strength and bendability |

| High rigidity, thin gauge | 5005-H18 or 5052-H34 | Higher yield strength for stiffness |

| Structural panels in marine / transport | 5052-H32 / H34 | Superior corrosion resistance and strength |

| Anodized architectural sheets | 5005-H14 / H16, special anodizing-quality coils | Uniform color and gloss across façade elements |

Processing & Fabrication Advantages

| Process | Performance of 5005 / 5052 Aluminum Strip Panels |

|---|

| Cutting & shearing | Clean edges, minimal burr with proper tooling |

| Punching | Good edge quality, especially in O, H14, H32 tempers |

| Bending & folding | Tight radii achievable; 5052 requires slightly larger radius in hard tempers |

| Welding | Compatible with common filler wires, limited loss of strength in H tempers near welds |

| Riveting & fastening | Compatible with aluminum and stainless fasteners with correct isolation |

| Adhesive bonding | Excellent with properly pre-treated surfaces |

Why Choose 5005 & 5052 for Aluminum Strip Panels

- Balanced combination of strength, weight reduction, and corrosion resistance

- Proven reliability in architectural, transportation, and marine environments

- Flexible surface finishing path: anodized, painted, brushed, or embossed

- Stable coil quality suited to high-speed composite panel and roll-forming lines

- Long service life with low maintenance when used with suitable coatings

By matching alloy, temper, thickness, and coating system to the end-use conditions, aluminum strip panels using 5005 and 5052 provide a durable, visually appealing, and cost-effective solution for modern building envelopes and engineered panel systems.