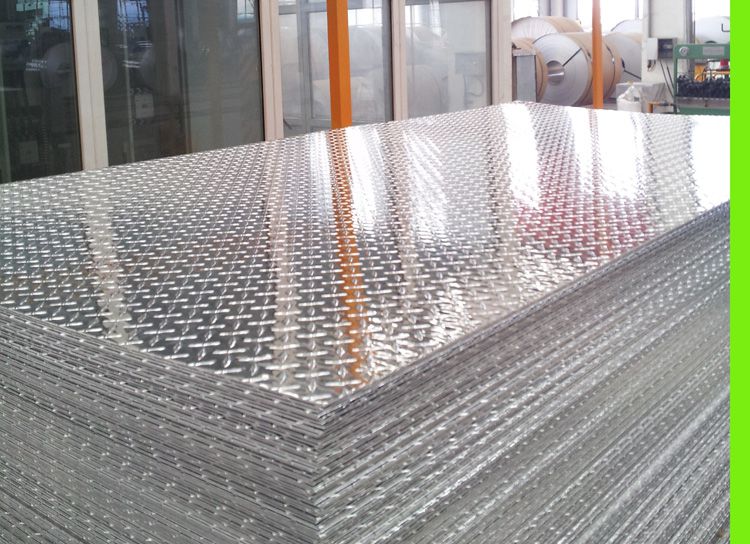

The 0.5mm AA1100 embossed aluminum sheet is a lightweight, decorative, and corrosion‑resistant material widely used for building decoration, interior finishing, HVAC, packaging, and appliance panels. Its combination of a pure aluminum alloy (AA1100) with an embossed surface pattern delivers both functional and aesthetic benefits.

| Item | Description |

|---|---|

| Product name | 0.5mm AA1100 Embossed Aluminum Sheet / Plate |

| Alloy grade | AA1100 (EN AW‑1100 / Al 99.0) |

| Temper | Commonly H14, H16, H18, O |

| Thickness | 0.5 mm (other thicknesses on request) |

| Surface pattern | Stucco, orange peel, diamond, hammered, etc. |

| Surface finish | Mill finish, embossing finish |

| Width range | Typically 600–1600 mm |

| Length form | Coil or cut‑to‑length sheet |

| Standard compliance | ASTM B209, EN 485, GB/T 3880 (or as required) |

Features

Lightweight and easy to fabricate

| Property | Typical Value / Behavior |

|---|---|

| Density | ~2.71 g/cm³ |

| Thickness | 0.5 mm (ultra‑light gauge) |

| Formability | Excellent; suitable for bending and shallow draw |

| Workability | Easy cutting, shearing, stamping, and folding |

| Joining | Suitable for riveting, adhesive bonding, some welding |

The thin 0.5 mm gauge significantly reduces weight while maintaining enough rigidity, especially when combined with the embossed texture that enhances stiffness.

High corrosion resistance

AA1100 is a commercially pure aluminum with very low alloy content, giving it outstanding resistance to:

- Atmospheric corrosion

- Moisture and condensation

- Many mild industrial and marine environments

This makes it ideal for outdoor decorative panels, HVAC duct jackets, and insulation cladding.

Attractive embossed surface

| Emboss Type | Visual Effect | Functional Benefit |

|---|---|---|

| Stucco / orange peel | Soft, textured, diffuse reflection | Hides fingerprints, minor dents, and scratches |

| Diamond / lentil | Geometric, reflective pattern | Improved grip, slip reduction in some uses |

| Hammered | Decorative, artisan‑like appearance | Strong visual interest for interior design |

The embossed texture:

- Reduces glare and diffuse light reflection

- Helps conceal small surface imperfections

- Increases perceived thickness and stiffness

Good thermal and electrical properties

| Property | Typical Range for AA1100 |

|---|---|

| Thermal conductivity | ~220–230 W/(m·K) |

| Electrical conductivity | ~57–60 % IACS |

| Melting range | ~643–657 °C |

| Service temperature | Typically up to ~150–200 °C (non‑load‑bearing) |

These properties support applications in insulation cladding, HVAC systems, and low‑voltage shielding or grounding components.

Chemical Composition (AA1100)

| Element | Content (wt.%) |

|---|---|

| Al | ≥ 99.00 |

| Si | ≤ 0.45 (Si + Fe) |

| Fe | ≤ 0.35 (Si + Fe) |

| Cu | 0.05–0.20 |

| Mn | ≤ 0.05 |

| Mg | ≤ 0.05 |

| Zn | ≤ 0.10 |

| Ti | ≤ 0.05 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

The high aluminum content ensures excellent corrosion resistance and formability, making it very suitable for decorative and cladding applications where complex shapes and bends are common.

Mechanical & Technical Specifications

Typical properties for 0.5mm AA1100 embossed sheet (values vary by temper and standard; for reference only):

| Property | Temper O | Temper H14 | Notes |

|---|---|---|---|

| Tensile strength Rm (MPa) | 60–100 | 110–145 | According to ASTM B209 / EN 485 |

| Yield strength Rp0.2 (MPa) | ≤ 30 | 95–125 | H14 is half‑hard |

| Elongation A50 (%) | ≥ 25 | 5–12 | Higher in soft temper |

| Brinell hardness HB | ~20–28 | ~30–40 | Depends on embossing and finish |

| Thickness tolerance (0.5 mm) | ±0.02–0.03 mm | ±0.02–0.03 mm | According to production standard |

| Flatness | ≤ 3–5 mm/m | ≤ 3–5 mm/m | Before embossing |

| Coating / film (optional) | PE, PVDF, PVC film | PE, PVDF, PVC film | For higher decoration or protection |

Dimensional Range & Supply Forms

| Parameter | Typical Range / Options |

|---|---|

| Thickness | 0.2–1.5 mm (0.5 mm focus specification) |

| Standard width | 600 / 800 / 1000 / 1200 / 1250 / 1500 mm |

| Custom width | Up to ~1600 mm (depending on mill) |

| Coil inner diameter | 505 mm or 610 mm |

| Coil outer diameter | Up to ~1500 mm |

| Coil weight | 0.5–3.0 MT, or as customer requirement |

| Sheet length | 1000–6000 mm, or cut to customer size |

Surface Quality and Options

| Feature | Description |

|---|---|

| Base finish | Mill finish, clean and uniform |

| Emboss depth | Usually 0.05–0.20 mm (pattern‑dependent) |

| Surface protection | Interleaved paper, PE protective film, or bare |

| Color coating (optional) | RAL colors, wood grain, stone pattern, etc. |

| Edge condition | Mill edge or slitted edge |

| Oil / dry | Lightly oiled or dry‑lubricated, as requested |

The embossed finish can be combined with color‑coated surfaces to create highly decorative and scratch‑resistant panels for interior and exterior design.

Main Applications

Building and architectural decoration

| Application Area | Typical Usage Description |

|---|---|

| Interior wall & ceiling panels | Light decorative cladding in malls, offices, stations |

| Column wraps & soffits | Cylindrical or curved decorative covers |

| Door skins and cabinet panels | Lightweight, corrosion‑resistant facing material |

| Elevator & corridor panels | Anti‑fingerprint, scratch‑concealing finishes |

The 0.5mm thickness is ideal where weight savings and flexible forming are more important than high structural strength.

HVAC and insulation cladding

| Component | Function of Embossed AA1100 Sheet |

|---|---|

| Duct jacket / duct covering | Protects insulation, resists weather and corrosion |

| Pipe insulation cladding | Wraps around insulated pipes indoors and outdoors |

| Tank / vessel cladding | Decorative and protective outer layer |

| HVAC housing panels | Lightweight covers and access doors |

The embossed texture increases stiffness and helps maintain appearance over time, even under minor handling impacts.

Transportation and packaging

| Field | Typical Use |

|---|---|

| Vehicle interiors | Ceiling liners, side panels, luggage racks |

| Protective covers | Machine and equipment protection panels |

| Industrial packing | Corrugated‑like wraps for large equipment |

The low weight of the 0.5mm sheet helps reduce overall vehicle mass and shipping costs.

Appliances and consumer products

| Product Type | Role of 0.5mm AA1100 Embossed Sheet |

|---|---|

| Refrigerators & freezers | Inner liners, decorative back panels |

| Kitchen equipment | Decorative fronts for cabinets, hoods |

| Lighting fixtures | Reflective yet diffused reflector surfaces |

| Exhibition displays | Temporary yet attractive paneling |

The combination of clean metallic appearance and textured surface is widely favored in modern home and commercial appliances.

Advantages Compared with Plain (Non‑Embossed) Sheet

| Aspect | Embossed AA1100 (0.5mm) | Plain AA1100 (0.5mm) |

|---|---|---|

| Appearance | Textured, decorative, hides imperfections | Smooth, more reflective, shows scratches more |

| Stiffness / rigidity | Slightly higher due to emboss profile | Lower, more prone to “oil canning” |

| Scratch visibility | Reduced; pattern camouflages marks | Scratches and dents more visible |

| Anti‑slip performance | Improved with diamond or lentil pattern | Limited |

| Light reflection | Diffuse reflection, less glare | Mirror‑like (for bright finish) or semi‑dull |

Processing and Fabrication Notes

| Operation | Suitability / Note |

|---|---|

| Cutting | Shearing, slitting, laser (with care to avoid burrs) |

| Bending | Good; bend radius should consider embossing direction |

| Deep drawing | Limited; better for shallow forming and light stamping |

| Welding | Possible (TIG, MIG), though pure Al has lower strength joints |

| Adhesive bonding | Very suitable with proper surface cleaning |

| Surface cleaning | Mild alkaline or neutral detergents recommended |

The embossed pattern can influence bending lines: bending parallel or perpendicular to the pattern may slightly change the bend quality and springback.

Why Choose 0.5mm AA1100 Embossed Aluminum Sheet?

| Benefit Category | Points |

|---|---|

| Cost‑effectiveness | Economical pure aluminum alloy with stable performance |

| Appearance | Decorative texture with modern metallic look |

| Weight & handling | Very light, easy to transport, handle, and install |

| Durability | Corrosion‑resistant and impact‑tolerant surface |

| Versatility | Works across building, HVAC, appliances, and packaging |

For customers seeking a material that is both decorative and functional—particularly where light weight and corrosion resistance matter—the 0.5mm AA1100 embossed aluminum sheet offers a balanced, reliable solution.