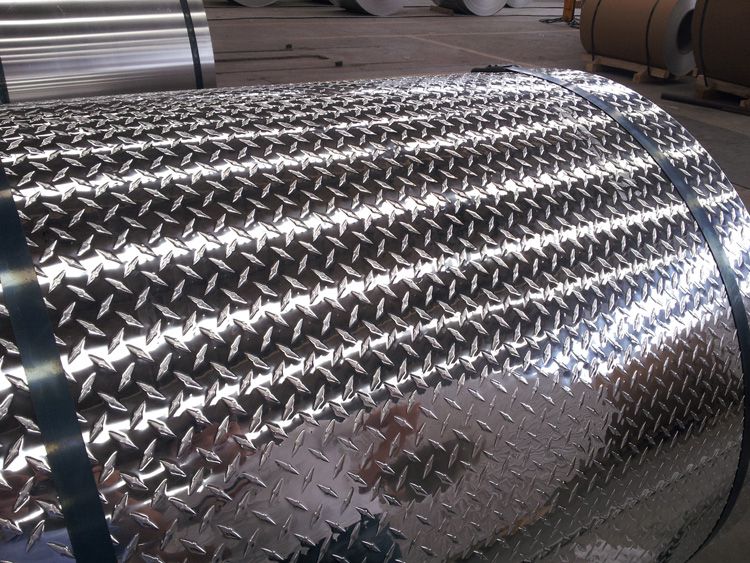

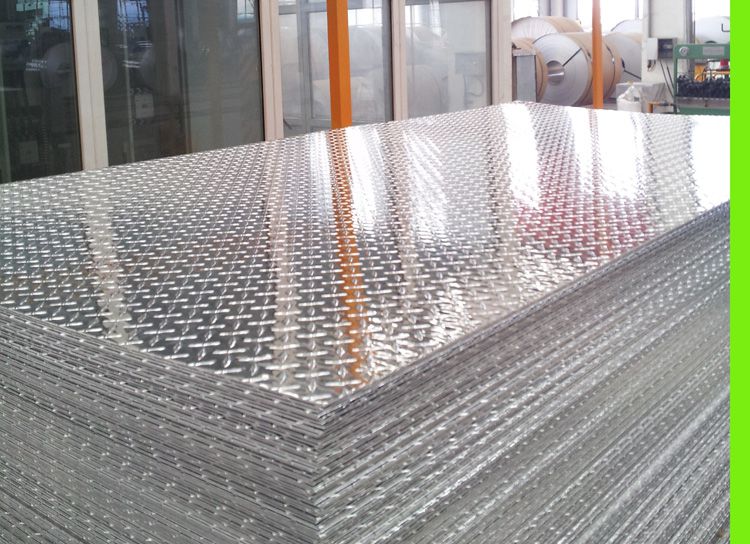

Stucco Embossed Aluminum Sheet for Decoration, Insulation & HVAC

Aluminum embossed sheet 1050 1060 1100 offers excellent corrosion resistance, formability, and thermal performance, ideal for insulation jacketing, HVAC ducts, refrigeration, decoration, and packaging. Available in stucco and other patterns, thickness 0.25–2.0 mm, widths up to 1600 mm, with stable surface quality and consistent embossing depth.

Aluminum embossed sheet in alloys 1050, 1060, and 1100 belongs to the 1xxx series commercially pure aluminum. Embossed (usually stucco) texture is mechanically rolled onto the surface, creating a decorative, slip‑resistant, and rigidity‑enhancing pattern.

These grades are widely used in:

- Thermal insulation jacketing for pipes, vessels, and equipment

- HVAC air-conditioning ducts and ventilation systems

- Refrigeration and cold storage lining

- Decorative panels and cladding for buildings and interiors

- Packaging and automotive heat shields

1050/1060/1100 share similar properties: high thermal conductivity, outstanding corrosion resistance, excellent formability, and non-toxic, lightweight characteristics.

2. Features & Advantages

2.1 Main Features

| Feature | Description |

|---|

| High purity aluminum | 99.0–99.6% Al content, guaranteeing high ductility and good corrosion resistance |

| Embossed / stucco surface | Increases surface strength and rigidity, hides small scratches, improves appearance |

| Excellent formability & workability | Suitable for bending, roll forming, spinning, and deep drawing |

| Good corrosion resistance | Performs well in urban, industrial, and mildly marine environments with suitable coating |

| High thermal reflectivity | Reflects radiant heat, effective for thermal insulation jacketing |

| Lightweight | ~2.71 g/cm³ density, reducing structural load vs steel |

| Easy to clean & maintain | Emboss/texture masks fingerprints and minor stains |

| Good weldability and adhesive bonding | Compatible with TIG/MIG welding, riveting, folding, and bonding |

| Recyclable & eco‑friendly | 100% recyclable without loss of performance |

| Smooth backside (optional PE film) | Back F side generally mill finish, optional PVC/PE protective film on surface |

2.2 1050 vs 1060 vs 1100 — Feature Comparison

| Property / Grade | 1050 | 1060 | 1100 |

|---|

| Nominal Al content | 99.5% | 99.6% | 99.0% min |

| Strength level | Lowest of three | Similar to 1050 | Slightly higher strength |

| Weldability | Excellent | Excellent | Excellent |

| Corrosion resistance | Excellent | Excellent | Excellent |

| Workability/formability | Excellent (deep draw friendly) | Excellent | Excellent (good for complex forming) |

| Typical applications | General emboss & insulation | Insulation jacketing, HVAC | Architectural, packaging, cookware base |

3. Typical Applications

3.1 Thermal & Cryogenic Insulation

- Pipe and tank jacketing for power plants, chemical plants, petrochemical, LNG facilities

- Insulation of chillers, storage tanks, air ducts, equipment enclosures

- Outer cladding for PU / rock wool / glass wool / cellular glass insulation systems

Benefits in insulation:

- Embossed surface reduces glaring reflection and improves handling grip

- Minimizes contact area between metal and insulation layer, helpful for moisture drainage

- Resistant to water, many chemicals, and external mechanical knocks (when used with proper thickness)

3.2 HVAC & Refrigeration

- Air-conditioning duct covers, turning vanes, flanges

- Refrigerated trucks and vans lining

- Cold room / freezer inside facing panels

- Defrost shields, drip trays, protective covers in refrigerators

3.3 Architectures & Interior Decoration

- Wall, ceiling, partition panels for industrial buildings or workshops

- Decorative cladding for elevators, corridors, manual protective walls

- Soffits and internal/external façade decoration (with appropriate coating or anodizing)

3.4 Others

- Packaging for machinery or sensitive equipment

- Automotive and motorcycle thermal shields

- Households: toolboxes, storage cabinets, shelves, anti-slip panels where light load applies

4. Alloy Chemical Composition

Typical compositions in accordance with GB/T, EN, or ASTM standards (reference values)

4.1 Chemical Composition – 1050 Aluminum Alloy

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others each | Others total | Al (min) |

|---|

| % max | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.03 | 0.10 | 99.50 |

4.2 Chemical Composition – 1060 Aluminum Alloy

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others each | Others total | Al (min) |

|---|

| % max | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.03 | 0.10 | 99.60 |

4.3 Chemical Composition – 1100 Aluminum Alloy

| Element | Si + Fe | Cu | Mn | Mg | Zn | Ti | Others each | Others total | Al (min) |

|---|

| % max | 0.95 | 0.05–0.20 | 0.05 | 0.05 | 0.10 | 0.05 | 0.05 | 0.15 | 99.00 |

5. Tempers and Mechanical Properties

1050/1060/1100 embossed sheets are commonly supplied in softer conditions suitable for forming and rolling over insulation molds.

5.1 Available Tempers

| Alloy | Common Tempers for Embossed Sheet | Description |

|---|

| 1050 | O / H12 / H14 / H24 / H26 | Soft to half‑hard; mostly O, H14, H24 |

| 1060 | O / H12 / H14 / H24 / H26 | Jacketing & ducting frequently O or H24 |

| 1100 | O / H12 / H14 / H16 / H18 / H24 | Slight strength gain; widely used in H14 / H24 |

“O” temper is annealed and very soft; “H” tempers are strain-hardened to different degrees.

5.2 Typical Mechanical Properties

(Indicative, may vary by standard, thickness, and production route)

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation A50 (%) | Typical Use |

|---|

| 1050 | O | 60–95 | ≥20 | 25–35 | Deep forming, jacketing with shaping |

| 1050 | H14 | 95–125 | ≥50 | 15–25 | General cladding, basic rigidity |

| 1050 | H24 | 100–135 | ≥60 | 12–20 | Ducts, panels needing higher strength |

| 1060 | O | 60–95 | ≥20 | 25–35 | Pipe jacketing, embossed coil |

| 1060 | H14 | 95–130 | ≥55 | 14–23 | HVAC plates, cladding |

| 1060 | H24 | 105–135 | ≥60 | 12–20 | Outdoor jacketing, transport |

| 1100 | O | 65–100 | ≥20 | 25–35 | Complex shaping, spinning |

| 1100 | H14 | 100–135 | ≥55 | 12–22 | Architectural panels, packaging |

| 1100 | H24 | 110–145 | ≥65 | ~10–20 | Heavy-duty jacketing & facing |

6. Dimension Range & Embossing Parameters

6.1 Standard Size Ranges

| Item | Typical Range / Specification |

|---|

| Thickness (embossed) | 0.25 – 2.0 mm (common: 0.3 / 0.4 / 0.5 / 0.7 / 0.8) |

| Width | 500 – 1600 mm (commonly 914, 1000, 1200, 1250 mm) |

| Coil Inner Diameter | 505 / 508 / 610 mm (cut‐to-length plates available) |

| Coil Weight | 0.5 – 3 tons typical, customized by request |

| Sheet Length | 1000 – 6000 mm or custom cut |

| Tolerance, thickness | ±0.02–0.05 mm (depends on standard & thickness) |

| Tolerance, width | ±2.0 mm typical; tighter tolerance optional |

Dimensions can be customized according to project and fabrication needs.

6.2 Embossing (Stucco) Parameters

| Parameter | Typical Value / Description |

|---|

| Emboss pattern type | Stucco (orange peel) standard; other patterns upon request |

| Embossing coverage | Full surface coverage, uniform texture |

| Embossing depth | Approx. 0.02 – 0.08 mm (per side) |

| Pattern regularity | Controlled pitch & spread for consistent appearance |

| Finish on bottom side | Mill finish (plain) or light brushed |

| Surface protections | Optional PE/PVC protective film; paper interleaving |

7. Physical Properties Relevant to Insulation & HVAC

7.1 Basic Physical Data

| Property | Typical Value (1xxx Series) |

|---|

| Density | ~2.71 g/cm³ |

| Melting Temperature | ~645–660 °C |

| Thermal Conductivity (20 °C) | 200–230 W/(m·K) |

| Linear Thermal Expansion | ~23.6 × 10⁻⁶ /K |

| Electrical Conductivity | ~58% IACS (depends on purity) |

| Emissivity (uncoated mill) | ~0.20–0.25 (can increase with oxides) |

| Emissivity (painted/coil coated) | 0.80–0.90 depending on coating |

High thermal conductivity & good reflectivity make these alloys ideal for insulation and cold systems.

8. Surface Finish & Coating Options

8.1 Standard Surface

| Side | Condition |

|---|

| Embossed F | Stucco embossed / bright / semi-matte |

| Backside B | Mill finish or lightly matt rolled |

8.2 Optional Surface Treatments

| Option | Description |

|---|

| Color coated (PE / PVDF) | Coil coated for exterior weather resistance & colored appearance |

| Anodized | Light decorative or erosive protection (limited for 1xxx alloys) |

| Degreased & chemically treated | Improved adhesion for glue, coating, or insulation facing tape |

| Laminated film | Film lamination for improved corrosion protection & decoration |

9. Performance Advantages in Real Use

9.1 Corrosion & Weathering Resistance

- Naturally forms an oxide film to resist oxidation

- Suitable for industrial atmosphere, slight marine and urban conditions

- When combined with coating or lamination, service life can extend to 15–30 years in jacketing applications (depending on environment and installation)

9.2 Structural & Handling Benefits

| Aspect | Behavior / Advantage |

|---|

| Weight | ~1/3 the weight of steel for same thickness |

| Rigidity | Embossing increases panel stiffness without extra thickness |

| Formability | Bends, folds and rolls easily on site |

| Safety | Embossed surface gives better grip, slightly reducing slip |

9.3 Aesthetic & Functional Appearance

- Stucco texture hides small surface flaws and fingerprints

- Reduces mirror reflections – more comfortable for workers in bright plant rooms

- Ensures more consistent visual effect across large walls & pipe racks

10. Typical Standards & Quality Control

10.1 Referenced Standards

| Region | Typical Standards |

|---|

| ASTM | B209 (Aluminum and Aluminum-Alloy Sheet & Plate) |

| EN | EN 485 / EN 573 (chemical & mechanical requirements) |

| GB/T | GB/T 3190 / 3880 series for 1xxx wrought aluminum |

10.2 Quality Control Items

| Control Item | Scope / Target |

|---|

| Chemical composition | Ensure compliance with selected alloy grade |

| Mechanical properties | Tensile, yield, elongation according to temper |

| Thickness, width | Within specified tolerances |

| Emboss uniformity | Uniform texture, no missing or blurred patterns |

| Surface defects | No major roll dents, oil spots, corrosion, stains |

| Coil shape | Low camber, minimal coil set, easiness in decoiling |

11. Packing, Protection & Handling

11.1 Packing Methods

| Item | Detail |

|---|

| Coil packing | Core with inner sleeve, plastic or kraft paper wrap, edge protectors, steel straps |

| Sheet packing | Wooden pallet or wooden case, plastic & paper interleave, strapping |

| Moisture protection | Desiccant bags, moisture-proof packaging (particularly export) |

| Surface protection | Optionally PE/PVC film on embossed side to prevent scratches |

11.2 Storage & Handling Recommendations

- Store in dry, ventilated warehouse, avoid acidic / alkaline vapor environments

- Keep original packing before use; protect edges from impact

- Use soft slings or rubber pad clamps when lifting to avoid deformation and scratches

12. How to Select Between 1050, 1060, and 1100 Embossed Sheet

| Requirement | Recommended Grade | Reason |

|---|

| Maximum purity, good flexibility | 1060 | Highest Al content, slightly better ductility |

| Balanced cost & availability | 1050 / 1060 | Large-volume, mature supply chain |

| Higher strength within 1xxx series | 1100 (H14/H24) | Cu addition slightly increases strength |

| Complex forms (deep drawing/spinning) | 1050 / 1060 / 1100-O | Very soft material for tight bending curves |

| Domestic and export insulation jacketing | 1060-H24 / 1060-O | Market mainstream, commonly accepted specifications |

13.1 Quick Technical Sheet

| Item | Data / Range |

|---|

| Product | Aluminum embossed (stucco) sheet & coil |

| Alloys | 1050, 1060, 1100 |

| Tempers | O, H12, H14, H16, H18, H24, H26 |

| Thickness | 0.25 – 2.0 mm (typical 0.3–1.2 mm) |

| Width | 500 – 1600 mm |

| Length (sheet) | 1000 – 6000 mm or customized |

| Coil ID | 505 / 508 / 610 mm |

| Pattern | Stucco (standard), other patterns on request |

| Surface | Embossed one side, plain backside |

| Standards | ASTM B209 / EN 485 / GB/T 3880 or agreed |

13.2 Main Advantages for SEO Focus

- Aluminum embossed sheet 1050 1060 1100 features high purity, corrosion resistance, and reliable formability, ideal for insulation jacketing and HVAC ducting.

- Stucco embossed aluminum sheet increases rigidity and slip resistance while keeping weight low.

- Thickness 0.25–2.0 mm, custom widths up to 1600 mm, and a range of tempers O / H14 / H24 meet various engineering requirements.