Below is a technical, engineering‑oriented look at A1100 H26 white coated aluminum coil—what the grade and temper really imply, how standards and parameters tie together, and why this alloy/temper/coating combination is selected for specific applications (ceiling, facade, interior panels, signage, enclosure casings, etc.).

1. What A1100 H26 Really Means in a Coated Coil

1.1 Alloy 1100 – Almost Pure Aluminum as a “Neutral” Base

A1100 is a commercially pure wrought aluminum (≥ 99.00% Al). In the coated coil industry, this “purity” is less about conductivity and more about:

- Predictable surface chemistry – stable oxide, excellent coating adhesion.

- Non‑hardening by heat treatment – mechanical properties are mainly controlled by cold work (H temper) and thickness.

- Excellent corrosion resistance – especially under paint films or lacquers.

- Good plasticity – suitable for light forming, bending, and clinching without cracking the coating (within limits).

1100 is widely accepted under standards such as:

- ASTM B209 – Aluminum and Aluminum-Alloy Sheet and Plate

- GB/T 3880.1 / 3880.2 – Aluminum and aluminum alloy sheet, strip for general applications

- EN 573-3 – Chemical composition (alloy designation: EN AW-1100)

1.2 Temper H26 – Designed for Shape Retention Under Coating

In coated coils, H26 is not just a temper code; it is a design choice:

- “H” = strain hardened (work‑hardened)

- “2” = strain hardened and then partially annealed

- “6” = approximate strength between H24 and H28, often simplified as “60% cold work” in product literature

In practice, A1100 H26 is selected when you need:

- Higher yield strength than H24, to resist oil-canning and panel deflection.

- Finite ductility retained by partial anneal, so roll forming, slitting, light bending and moderate profile forming are possible without micro-cracking the paint (within proper radii).

Typical mechanical properties for A1100 H26 (indicative, not guaranteed values):

- Tensile Strength: ≥ 125 MPa

- 0.2% Yield Strength: ≥ 105 MPa

- Elongation (L0 ≥ 50 mm): 3–7% (depends on thickness)

Exact guaranteed values follow the relevant purchasing and product standard (ASTM/GB/EN plus factory specification).

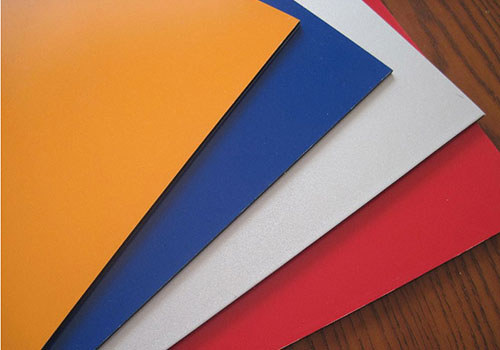

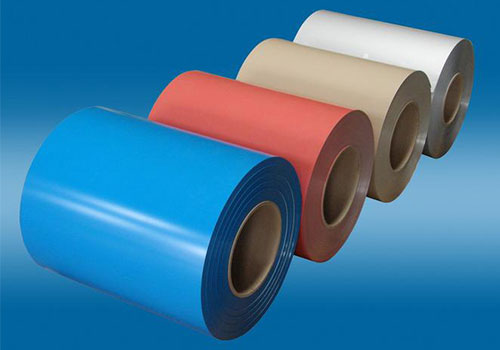

2. White Color Coated Surface: An Engineered Optical Layer

The white surface on A1100 H26 coil is not simply “painted aluminum”; it is a coordinated coating system:

2.1 Typical Coating Systems

- Polyester (PE) white coil coating

- Good color richness, economic option.

- Suitable for interior roofing, ceiling, decorative panels, advertising panels.

- Polyvinylidene Fluoride (PVDF) white coil coating

- Excellent UV and chalking resistance.

- EN 13523 / AAMA 2604/2605 compliant systems often used on facades and external cladding.

2.2 Optical & Application Parameters

White color coatings on A1100 are often evaluated under:

- Color tone & stability:

- CIE Lab* reading vs. standard;

- ΔE ≤ 1.0–1.5 (lab standard control) for good batch consistency.

- Gloss level:

- Classified as matt (10–30 GU), silk (30–60 GU), or high gloss (≥ 70 GU) at 60°.

- Matching gloss to application: matt/silk for interior ceilings, higher gloss for signage and appliances.

- Film thickness:

- Top coat: typically 18–25 μm (PE) or 25–30 μm (PVDF).

- Primer: 5–7 μm.

- Back coat: 5–10 μm, depending on bonding/adhesion requirements.

Integrating the coating parameters with the substrate temper is critical: higher film thickness improves anticorrosion and UV resistance but increases sensitivity to tight bending radii; H26 ensures enough panel rigidity without being too brittle for common fabrication.

3. Implementation Standards and Test Methods

A1100 H26 white color coated aluminum sheet coil generally aligns with:

- Base aluminum standards

- ASTM B209 / B209M

- GB/T 3880.2

- EN 485‑2 (mechanical properties), EN 573‑3 (chemistry)

- Coil coating & paint performance standards

- EN 13523 series (coil coated metals – test methods)

- ISO 2813 (gloss), ISO 2409 (cross-cut adhesion)

- AAMA 2603 / 2604 / 2605 for architectural performance levels

- Coating line QA benchmarks

- T‑bend test: typical requirement T2–T3 or better (no cracking for certain systems)

- Impact resistance: e.g., ≥ 50 kg·cm without paint peel

- Salt spray resistance (ASTM B117 or ISO 9227):

- PE systems: ~500–1,000 h no base metal corrosion beyond set criteria

- PVDF systems: often ≥ 1,500 h

Adoption of these standards dictates how coil is specified and contracted between supplier and end user.

4. Chemically Pure – But Functionally Tuned: A1100 Composition

4.1 Nominal Chemical Composition of A1100

Typical limits according to common standards (wt.%):

| Element | Typical Range / Max (wt.%) | Functional Note |

|---|---|---|

| Al | ≥ 99.00 | High purity for adhesion, corrosion resistance, conductivity |

| Si | ≤ 0.45 | Improves fluidity, slightly affects strength |

| Fe | ≤ 0.35 | Impurities controlled to keep ductility and surface quality |

| Cu | 0.05 – 0.20 | Slight strength increase but too much harms corrosion resistance |

| Mn | ≤ 0.05 | Traces help refine grain |

| Mg | ≤ 0.05 | Controlled low to maintain “non-heat-treatable” behavior |

| Zn | ≤ 0.10 | Minimizes galvanic side effects |

| Ti | ≤ 0.03 | Grain refiner |

| Others (each) | ≤ 0.05 | Trace clean-up elements |

| Others (total) | ≤ 0.15 |

Exact composition follows the specified standard (ASTM, EN, GB) and mill practice.

4.2 Why This Matters in a White Coated Coil

- A clean Al–Fe–Si matrix provides a uniform oxide layer, critical for pretreatment and consistent coating adhesion.

- Low Cu + high Al purity = enhanced resistance to under‑film corrosion, avoiding blistering or filiform corrosion in the white top coat.

- Tight composition control improves the predictability of surface conversion layers (e.g. chromate-free pretreatments), making color and adhesion more stable from coil to coil.

5. Physical & Mechanical Parameters – What You Actually Specify

5.1 Dimensional & Tolerance Parameters

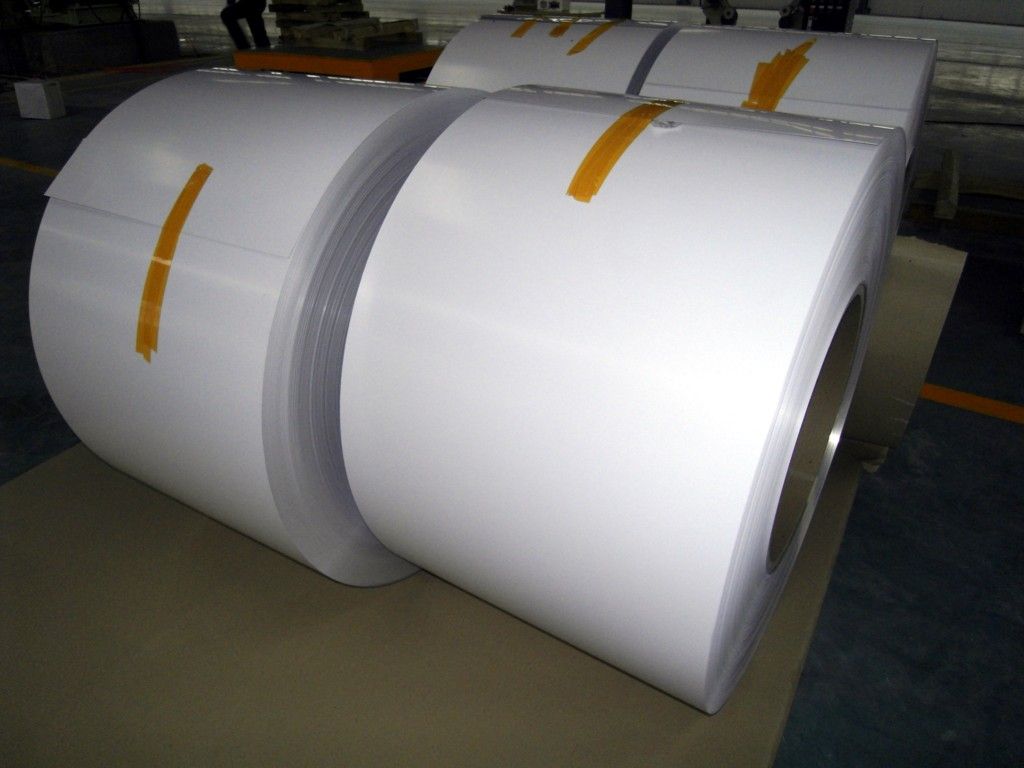

Common specification ranges for A1100 H26 white color aluminum sheet coil:

- Thickness: 0.20 – 1.2 mm for typical facade/ceiling/decoration profiles

- Width: up to 1,250 – 1,600 mm (line-dependent)

- Coil ID: φ 405 mm / 505 mm / 508 mm / 610 mm

- Coil OD: typically up to 1,500 – 1,800 mm

Thickness and width tolerances follow:

- ASTM B209,

- GB/T 3880.2 or

- equivalent EN 485‑4 tolerances.

5.2 Mechanical/Performance Benchmarks (Indicative)

For well‑produced A1100 H26 white color coil:

- Tensile Strength: 125–150 MPa

- Yield Strength: 105–130 MPa

- Elongation: 3–7% (depending on thickness & standard gauge length)

- Pencil hardness of coating: HB–2H (depending on paint system)

- Cross-cut adhesion: Grade 0 (no peeling) as per ISO 2409

- Coating flexibility: T2–T3 no cracking visible to naked eye

- Reverse impact: ≥ 50 kg·cm without paint loss (typical spec)

These values balance between enough strength for stiffness and sufficient ductility for practical fabrication of panels and trim parts.

6. Where the Alloy–Temper–Coating Combination Makes Sense

6.1 Targeted Application Segments

- Interior and semi-exterior ceilings

- Linear strip ceilings, clip-in ceilings, open cell ceilings.

- Benefits: light weight, good flatness, easy installation, stable white shade.

- Coil-based facade cassettes and cladding profiles

- Especially for low to mid wind load zones or where complex structural loads are minimal.

- White enhances solar reflectivity and aesthetics.

- Signboards and display panels

- Uniform color and smooth surface are essential; A1100 provides stable planar surfaces.

- Electrical & electronic enclosures, appliance casings

- Non‑magnetic, high thermal conductivity, stable coating adhesion.

6.2 Choosing H26 vs Other Tempers for Coated Materials

- H14 / H16: softer; more formable but less stiff; higher risk of panel waviness.

- H24: mid strength, more elongation; better for deeper drawn parts.

- H26 (focus): fitter for flat panels and shallow formed profiles requiring shape retention and surface regularity, typical for ceilings/facades/signage.

- H28: very high strength but often too brittle for coated bending and roll forming without cracking risk.

Thus A1100 H26 white coil is particularly suitable where:

Forming depth is low to moderate, geometric stiffness is mainly from profile, and long‑term flatness and appearance are as important as basic mechanical strength.

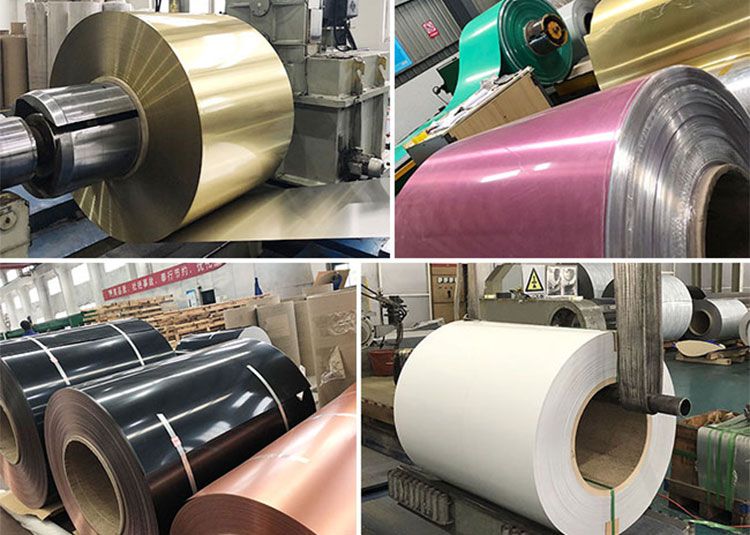

7. Process View: How Quality Is Engineered, Not Inspected

To understand performance consistency, it helps to look at the process chain:

Casting & Hot Rolling of 1100 Slab

- Control of Fe/Si dispersion, minimizing inclusions; influences surface smoothness and anodic/cathodic neutrality beneath coating.

Cold Rolling to Target Gauge & Temper (H26)

- Cold reduction % finely tuned to hit the strength–ductility window needed for a specific application.

- Final anneal/partial anneal defines “H26” character—too much anneal and it behaves like H24; too little and bendability suffers.

Surface Pretreatment

- Alkaline or acidic cleaning → neutralization → conversion coating (often chromate‑free).

- This stage designs the interfacial chemistry that governs long‑term paint adhesion and corrosion resistance.

Coil Coating Line

- Roll‑coating with primer → curing → topcoat → curing.

- Oven profile (time/temperature) tuned to produce optimized cross‑link density, affecting hardness, gloss retention, chalking rate.

Quality Testing

- All mechanical & coating tests: gloss, color ΔE, bend, impact, salt spray, MEK rubs for curing state.

- Only after correlating these properties is the coil slit or re‑coiled as product.

From this angle, A1100 H26 white color aluminum sheet coil is not just “white metal”; it is the intersection of metallurgical state, thermal history and polymer chemistry.

8. Specification Checklist (For Engineers and Buyers)

When specifying or evaluating A1100 H26 white color coated aluminum sheet coil, the essential items to define are:

- Alloy & Temper: A1100 H26 (EN AW‑1100 H26, AA1100 H26, or GB/T 1100 H26 equivalent)

- Standards: ASTM/EN/GB for substrate + EN 13523 & AAMA level for coating

- Dimensions:

- Thickness (e.g. 0.45 / 0.5 / 0.7 mm)

- Width (e.g. 600–1,250 mm)

- Coil ID/OD

- Coating System:

- Resin: PE or PVDF (and fluoropolymer content if relevant, e.g., ≥70% PVDF)

- Total coating thickness top/bottom

- Color code: RAL / Pantone, target ΔE tolerance

- Gloss range

- Mechanical Core Requirements:

- Minimum tensile and yield strength

- Minimum elongation

- Allowed bending radius (inside radius ≈ 1–1.5 × thickness, depending on coating)

- Performance Requirements:

- Adhesion, T-bend, impact

- Salt spray hours and evaluation criteria

- UV/chalking resistance class (if exterior use)

- Packaging & Storage Conditions:

- Eye to sky/eye to side requirement, vertical/horizontal packing;

- Anti‑moisture wrapping and interleaving to protect the white finish.