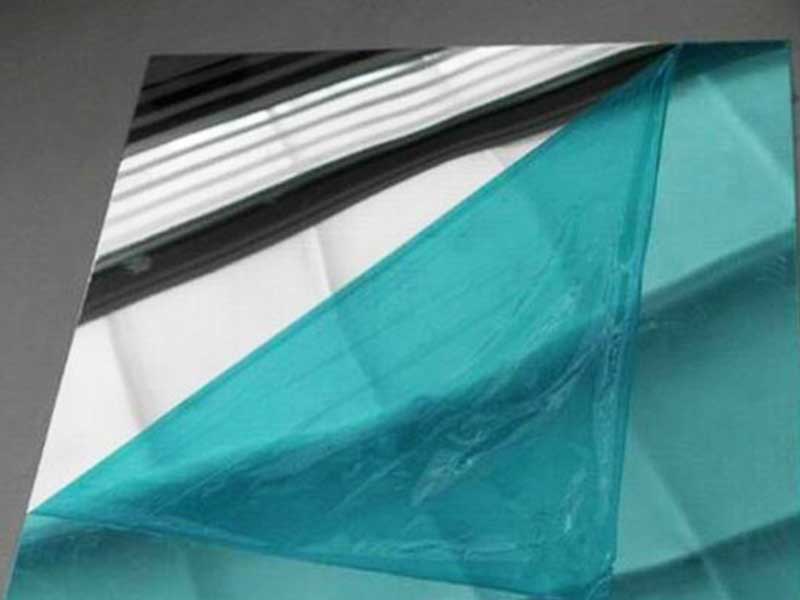

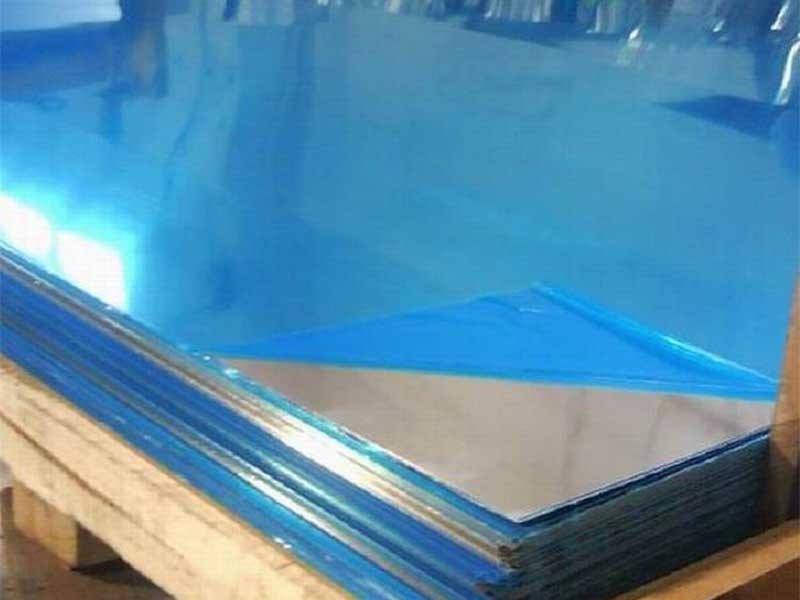

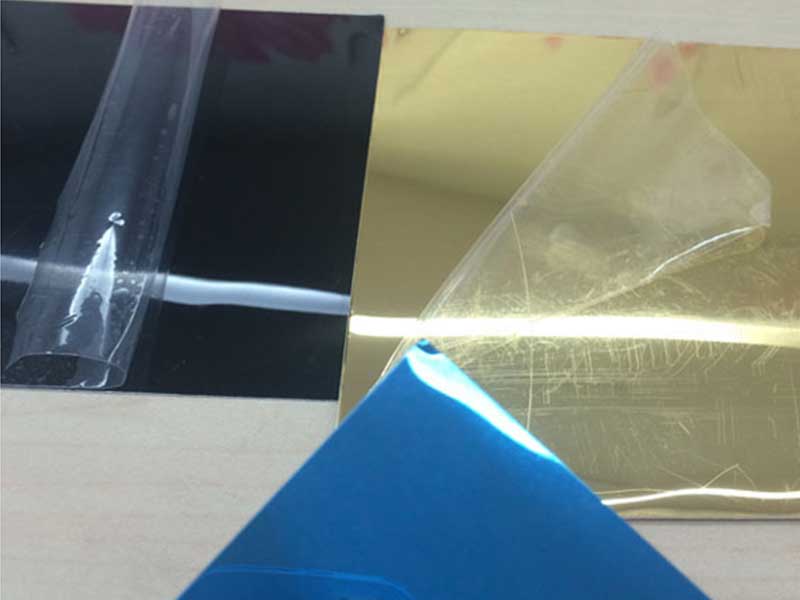

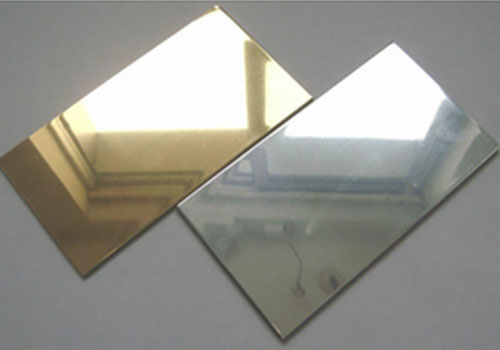

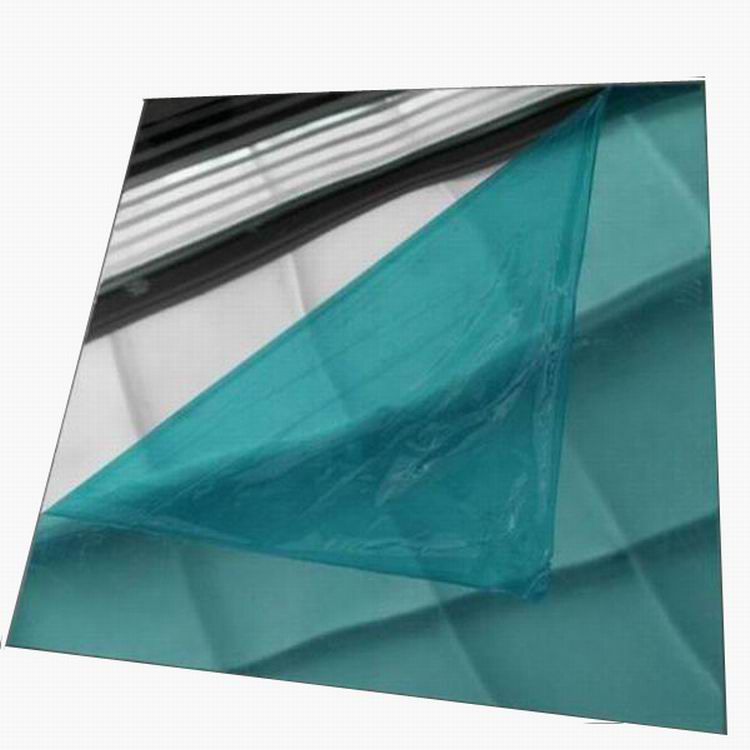

When discussing aluminum sheets, particularly reflective ones, very few things can match the exceptional qualities of the 1060 0.25mm mirror finish reflective aluminum sheet. Renowned for its versatility and aesthetic appeal, this product serves multiple industries—from decorative applications in architecture to functional uses in electronics and aerospace. To fully unravel its brilliance, we'll dive into its specifications, advantages, uses, and chemical properties.

Specifications and Technical Parameters

Here's a detailed look at some technical specifications of the 1060 mirror finish aluminum sheet:

| Property | Value |

|---|---|

| Material Alloy | 1060 |

| Thickness | 0.25 mm |

| Finish | Mirror |

| Temper | O (Annealed) |

| Width | Varies (commonly 1000mm, 1220mm) |

| Length | Customizable (based on requirement) |

| Density | About 2.7 g/cm³ |

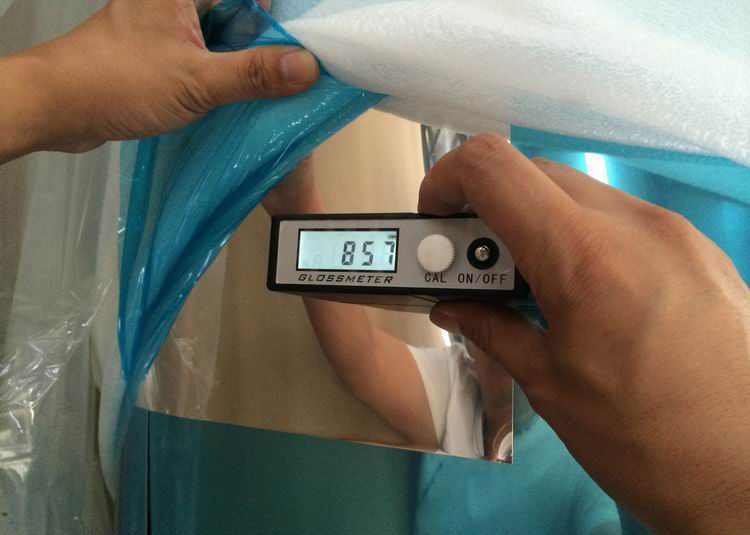

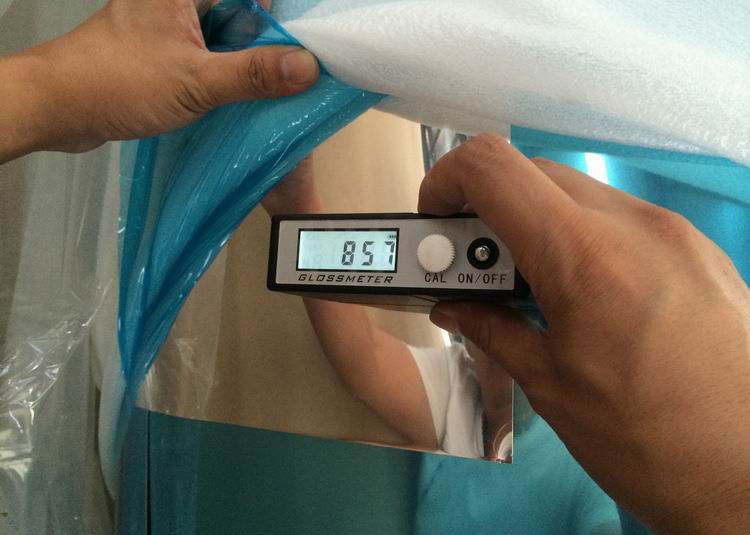

| Reflectivity | 85% or more |

| Tensile Strength | Approx. 110 - 130 MPa |

| Elongation at Break | 15-20% |

| Conductivity | Excellent (approximately 37.68×10^6 S/m) |

Alloy Tempering and Its Significance

The 1060 series aluminum sheet is recognized for its pure aluminum content (typically 99.6%). The '0' designation refers to the manufacturing process of annealing (the “O” tempers) which encourages malleability, subsequently facilitating applications requiring intricate bending and rolling without the risk of cracking or breaking. This quality significantly benefits industries that fabricate lightweight but durable components, shaping design freedom while retaining integrity. This reflects a remarkable attribute further contributing to applications across lighting systems, vehicles, or decorations trodden on heart.

Implementation Standards

The 1060 mirror aluminum sheet adheres to exacting standards characterized by solid international legislation, offering a set of implementations via different parameters summarized below:

- ASTM B221: Concerning standard specification for Aluminum and Aluminum-Alloy Extruded Bars, Rods, Tubes, Shapes, and Forgings.

- ASTM B737: Embraces standard practices for sizing of aluminum wire and it's often applied to various products requiring durability against higher operational intensities under atmospheric conditions.

- ISO 9001: A certification basis ensuring that a manufacturing unit has rigorous processes to uphold quality management.

Chemical Properties Table

the innovative characteristics of a 1060 0.25mm aluminum sheet also extends towards the chemistry. Here’s a succinct overview:

| Element | Weight Percent (min) |

|---|---|

| Aluminum (Al) | 99.6% |

| Iron (Fe) | 0.25% |

| Copper (Cu) | 0.05% max |

| Manganese (Mn) | 0.05% max |

| Magnesium (Mg) | 0.05% max |

| Silicon (Si) | 0.25% max |

| Zinc (Zn) | 0.05% max |

| Other Elements | Remaining total is minutely tolerant |

Unique Applications and Advantages

The mirror finish on a 1060 aluminum sheet does far more than just lighting up a meeting room; it plays vital roles across its embodiments. Several industries find specific advantages in utilizing this product:

Architectural Design & Decor: The aesthetic reflective property mirrors vibrant designs and provides depth, creating significant impacts in features such as wall panels and ceilings.

Electronics & Thermal Management: Through efficient heat conduction and resistance, it's utilized in components that necessitate reflection and protection, especially aimed towards achieving optimal thermal management.

Automotive Rotand Placement: With low weight, high reflectance and durability, fabricating trims, dashboards or lighting enclosures becomes effortless without a dent in their coordination standards.

In light of environmental consciousness, the reflective surface also bolsters energy efficiency through the absorption and reflection of light, leading to lower material usage on light fixtures and HVAC units—truly an ecoluminary design element.