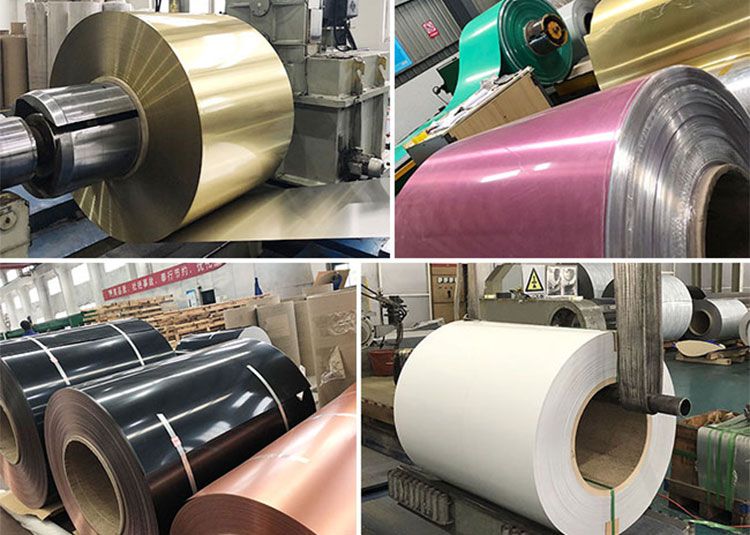

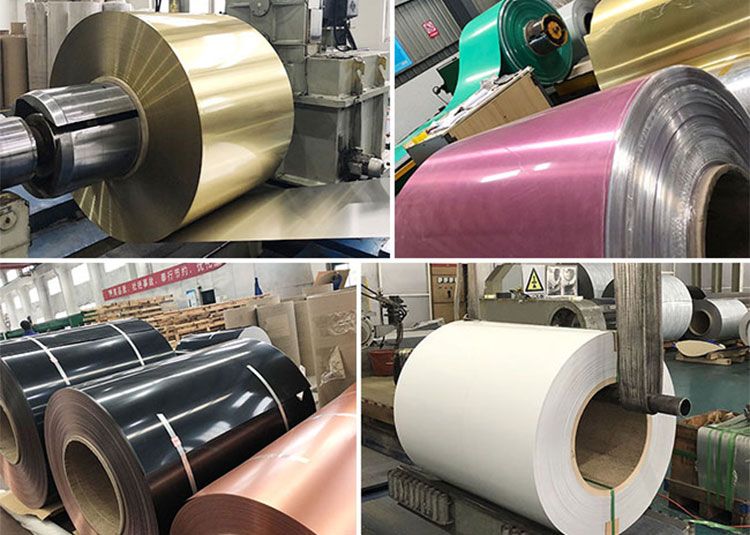

Color coated aluminum sheet coil strip is a product made of aluminum coil as the base material after surface paint coloring treatment. The common coatings are fluorocarbon coating, polyester coating, etc.

Because of its good flatness, decoration, weather resistance, mechanization and environmental protection, it is widely used in aluminum plastic panels, industrial factory roof walls, aluminum louvers, composite panels, aluminum ceilings, pop cans and electronic products.

The coating selection of coated aluminum coils can be considered according to their application fields and project cost requirements. The coating can be divided into PVDF fluorocarbon, HDP high weather resistant polyester, PE polyester ect., according to the weather resistance and anti-corrosion performance of the coating.

Specification:

✔ Thickness: 0.02mm~0.60mm

✔ Width: 1240mm, 1270mm, 1520mm, 1570mm etc.

✔ Color: refer to our standard color catalogue, also can produce according to customer’s requirements.

✔ Max Diameter: 1200mm

✔ Weight: 2.5 Ton/Coil; 3 Ton/Coil.

✔ Interior Diameter: 505mm or 405mm.

Application:

PE Coil is widely and mainly used for building decoration, such as ACP, aluminum ceilings, aluminum sheets, honeycomb panels and aluminum roofing, lighting decoration, household electrical appliance, food package, furniture etc.

Performance Parameter:

1.Thickness<= 0.50mm

Items | Test Item | Standard | National Standard | Test Report |

1 | Color Difference | ECCA T3 | △E<= 2.0 | △E<= 1.5 |

2 | Gloss Difference | ECCA T2 | <= 10 | <= 5 |

3 | Coating Thickness | ECCA T1 | Min 14 Micron | Min 16 Micron |

4 | Pencil Hardness | ASTM D3363 | >= HB | >= HB |

5 | T-Bend | ASTM D4145 | <= 3T | <= 2T |

6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

7 | Impact | ASTM D2794 | >= 20Kg.cm | >= 20Kg.cm |

8 | Boiling Water Resistance | GB/T 17748 | 2h no change | 2h no change |

9 | Solvent Resistance | ASTM D2248 | 200times paint | 200times paint |

10 | Salt Resistance | ASTM B117 | 720Hrs<= Grade 1 | 720Hrs<= Grade 1 |

11 | Dirt Resistance | GB/T 9780 | <= 5% | <= 5% |

12 | Color Retaining | GB/T16259 | 600 hrs△E<= 2 | △E<= 2 |

13 | Gloss Weaken Level | 600 hrs <= Grade 2 | <= Grade 2 | |

14 | Chalking | 600 hrs no change | no change |

2.Thickness> 0.50mm

Items | Test Item | Standard | National Standard | Test Report |

1 | Color Difference | ECCA T3 | △E<= 2.0 | △E<= 1.5 |

2 | Gloss Difference | ECCA T2 | <= 10 | <= 5 |

3 | Coating Thickness | ECCA T1 | Min 14 Micron | Min 16 Micron |

4 | Pencil Hardness | ASTM D3363 | >= HB | >= HB |

5 | T-Bend | ASTM D4145 | <= 3T | <= 2T |

6 | Adhesion | ASTM D3359 | Grade 0 | Grade 0 |

7 | Impact | ASTM D2794 | >= 20Kg.cm | >= 50Kg.cm |

8 | Boiling Water Resistance | GB/T 17748 | 2h no change | 2h no change |

9 | Solvent Resistance | ASTM D2248 | 200times paint | 200times paint |

10 | Salt Resistance | ASTM B117 | 720Hrs<= Grade 1 | 720Hrs<= Grade 1 |

11 | Dirt Resistance | GB/T 9780 | <= 5% | <= 5% |

12 | Color Retaining | GB/T16259 | 600 hrs△E<= 2 | △E<= 2 |

13 | Gloss Weaken Level | 600 hrs <= Grade 2 | <= Grade 2 | |

14 | Chalking | 600 hrs no change | no change |