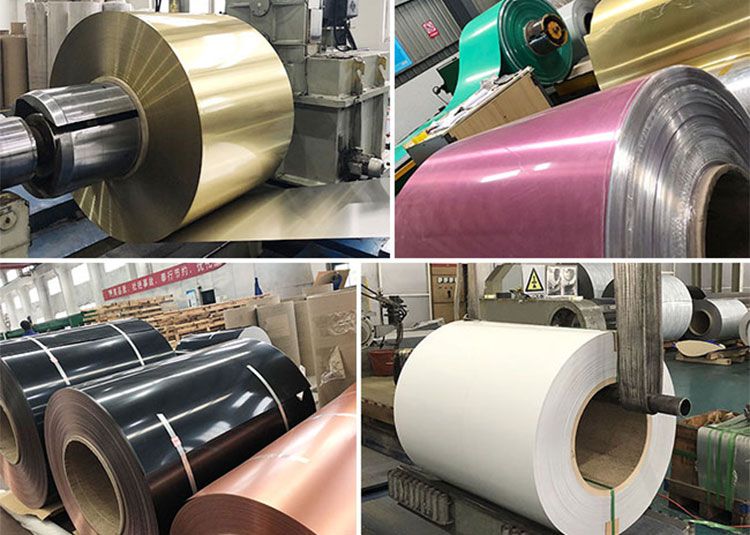

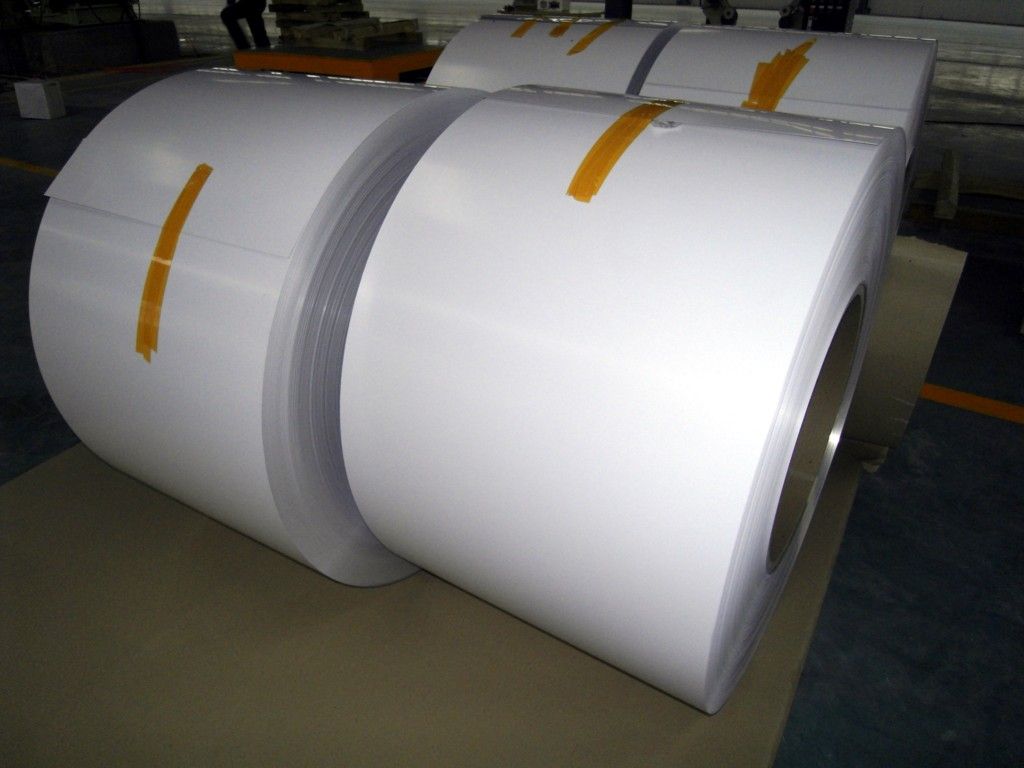

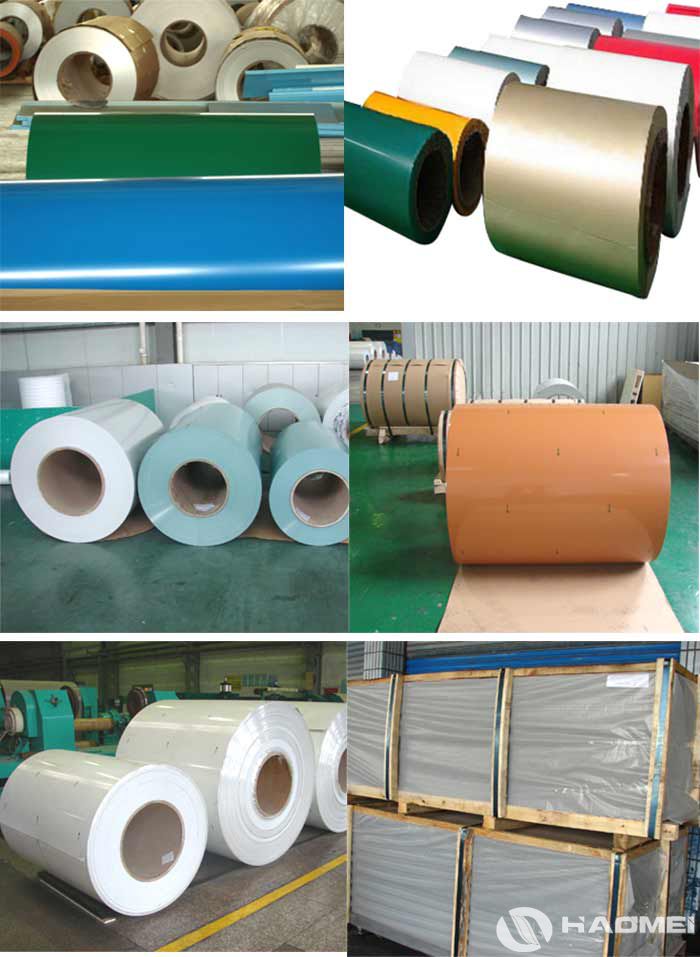

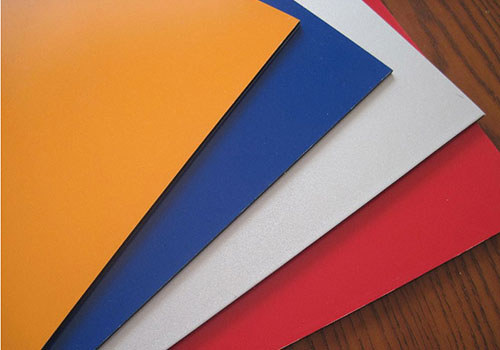

In an era of innovations where lightweight and durable materials drive numerous industries, color coated aluminum plates is know due to their versatility, aesthetic value, and excellent sustainability properties. Among the rich variety of aluminum alloys, 1100, 3003, 3105, and 5052 insulated aluminum plates pose substantial advantages suited to a myriad of applications. This comprehensive analysis explores their functions, unique applications, technical details, standards, alloy tempering, and chemical properties.

Aluminum alloys are referred to by their principal alloying elements and fall under a numerical designation. The series and the meanings behind them are:

1100 (Pure Aluminum): Marked primarily with 99% aluminum content, it’s known for excellent corrosion resistance, good conductivity, and ductility. The low tensile strength makes it ideal for intricate forming processes.

3003 (Aluminum-Manganese Alloy): Containing approximately 1.25% manganese, the 3003 alloy provides improved strength and corrosion resistance when compared to the 1100 series, making it widely used in producing applications needing moderate strength characteristics.

3105 (Aluminum-Manganese-Magnesium Alloy): Boasting an alloy consisting of 98% aluminum with colling additions of manganese and magnesium, the 3105 alloy is known for further enhancements in mechanical strength alongside superior workmanship qualities desirable in residential siding and mobile homes.

5052 (Aluminum-Magnesium Alloy): A higher strength variant designed for moderate-to-high-stress applications as it encompasses around 2.5% magnesium; it also resists fatigue which makes it suitable in marine or automotive contexts.

Functionality

The color-coated aluminum plates are not just aesthetically pleasing but come infused with value owing to their multitude of functional benefits:

Corrosion Resistance: Each series proffers inherent resistance to corrosive elements, especially pertinent for outdoor applications. Their coating hardships shield against moisture, extending physical integrity over time.

Voice and Heat Absorption-properties: Due to thermoplastic capabilities, they exhibit palpable thermal coefficient advantages, often replacing more energy-intensive materials in applications.

Aesthetic Versatility: Showcasing a vibrant palette and effects tied to their coated facades enables architects and builders to encourage unique, artistic expressions encouraged through creativity and design.

Machinability and Workability: The aforementioned alloys provide easy machinability, which allows aggressive finishing, cutting, welding, and processing standards bolstered by versatile pretreatments on coated versions.

Applications

Here are noteworthy applications categorized by specific industry use and emphasizing coefficient adherence to market demands.

Working with 1100, 3003, 3105, and 5052 color-coated aluminum plates daily gives me a unique appreciation for the subtle differences in their workability and final product characteristics. 1100, with its pure aluminum composition, is a dream to work with – incredibly formable and easy to coat, resulting in a consistently smooth, vibrant finish. However, its softness makes it less ideal for applications demanding high strength. 3003, with its manganese alloying, offers a nice balance of formability and strength, making it a popular choice, but the slight increase in hardness can sometimes lead to minor coating inconsistencies if the coating process isn't precisely calibrated. 3105, a higher-strength alloy, pushes the limits of formability, demanding more careful handling and tooling to avoid cracking during bending or stamping. Finally, 5052, with its magnesium alloying, is a fantastic choice for corrosion resistance, perfect for outdoor applications, although its slightly less ductile nature needs to be considered during the design phase.

The color coating itself is another layer of complexity. Achieving uniform color and adhesion across these different alloys requires a deep of the surface preparation and the specific properties of each alloy. For instance, the slightly different surface oxidation rates can affect the bond strength of the coating. We constantly monitor and fine-tune our coating parameters to ensure consistent quality across

Construction Uses: Commonly applied in façades, doors, windows, roof panels, and siding. Its aesthetics align flawlessly for those elements meant for enhanced design with longevity herein.

Transport Applications: Within the automotive and marine sectors, alloys like 5052 thrive and prove trusted choices, demarcating painted surfaces; they transpose styling options along principles of lower body weight for greater fuel efficiency.

Consumer Manufacturing: Predominantly for products such as appliance cladding. Color-coated stabilized finishes amplify purity and translate multiple marketing opportunities.

Signage Industries: Reflective properties lend themselves effectively to billboards and modest typical signage deployments.

Technical Specification Table

Below provides a concise perspective into elemental representations as opposed within the multitude of frameworks:

| Property | 1100 | 3003 | 3105 | 5052 |

|---|---|---|---|---|

| Aluminum | 99.0 | 98.1 | 98.0 | 97.0 |

| Density (g/cm³) | 2.70 | 2.73 | 2.73 | 2.68 |

| Yield Strength (MPa) | Up to 70.0 | Effective yield 120 | Good yield 125 | Resilient yield 210 |

| Elongation (%) | Extremely high (25 Ed) | Up to 20 | Around 15 | Robust at 12 |

| Corrosion Resistance | Excellent | Good | Better | Exceptional intake |

| Coating Standard | AAMA 2605 | Enable AAMA 2605 | Trust in 2604 | Supported against 2604 |

Implementation Standards

Acceptance standards such as American Architectural Manufacturers Association (AAMA) are adhered to hold up durability as higher-class coatings grant cutting peculiar qualities for ongoing incidents. Pre-coating by standardized labels aligns thermal suspension measures sought globally for architectural features demanding glorification alongside performance metrics conforming towards product fidelity engagement.

Alloy Tempering

Aluminum temper reference classifications ensure respective securing through different heat treatments enhancing characteristic retains. Heat processing for rolled sheets (like that typically adapted from cold rolling) strikes adjustable functional traits when gears finish enhancements optimizing workshop deployability.