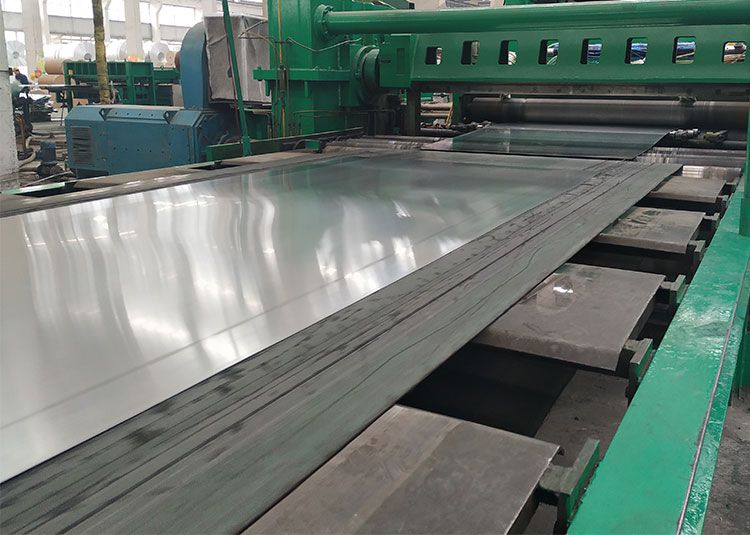

5005 H36 Aluminum Plate: The "Quiet Performer" for Clean Looks and Confident Forming

If you judge aluminum only by strength numbers, 5005 H36 aluminum plate can look modest on paper. But that misses why this alloy-temper combination is chosen again and again in real projects. 5005 H36 is the material people pick when the finished surface must look calm and consistent, when light forming is needed without drama, and when corrosion resistance must be dependable without heavy coatings. Think of it as a "quiet performer": it rarely demands attention during fabrication, yet it delivers a finished result that feels intentionally high-quality.

5005 is a non-heat-treatable, magnesium-bearing aluminum alloy in the 5xxx family. Its strengths come from solid-solution strengthening and work hardening rather than precipitation heat treatment. The H36 temper indicates it has been strain-hardened and then stabilized to a defined level of strength and formability. In practical terms, H36 sits in the "stronger than soft sheet, still workable" zone that suits panels, trims, architectural elements, and general-purpose plate applications where appearance and corrosion behavior matter as much as mechanical performance.

What the H36 temper really means in a workshop

"Temper" can sound abstract until you connect it to what operators and buyers care about: bending behavior, springback, flatness stability, and surface quality after processing.

H36 belongs to the H3x category, which generally indicates strain hardening followed by stabilization. Stabilization helps reduce the risk of property drift over time and improves consistency after forming or mild thermal exposure. Compared with softer tempers, 5005 H36 typically offers better dent resistance and stiffness for panels. Compared with higher work-hardened tempers, it can be more forgiving during forming and less prone to cracking at tight radii, depending on thickness and bend direction.

From a "finished look" perspective, 5005 is widely valued for its anodizing response. While 6061 is famous for strength and machinability, it can show color variation after anodizing. 5005 is often selected when a uniform anodized finish is a priority for consumer-facing or architectural surfaces.

Typical applications that benefit from 5005 H36

5005 H36 aluminum plate is frequently used where you want the metal to behave predictably across multiple steps: cutting, routing, forming, fastening, and finishing.

Common uses include architectural wall panels, decorative trims, interior and exterior cladding, appliance panels, signage backplates, lighting components, and enclosures that need corrosion resistance without excessive weight. In many of these applications, the "real product requirement" is not maximum tensile strength-it is a clean surface, stable performance in humid or mildly industrial environments, and a temper that doesn't fight back during fabrication.

parameters customers usually evaluate

When specifying 5005 H36 aluminum plate, buyers typically focus on a set of parameters that translate directly into fabrication outcomes.

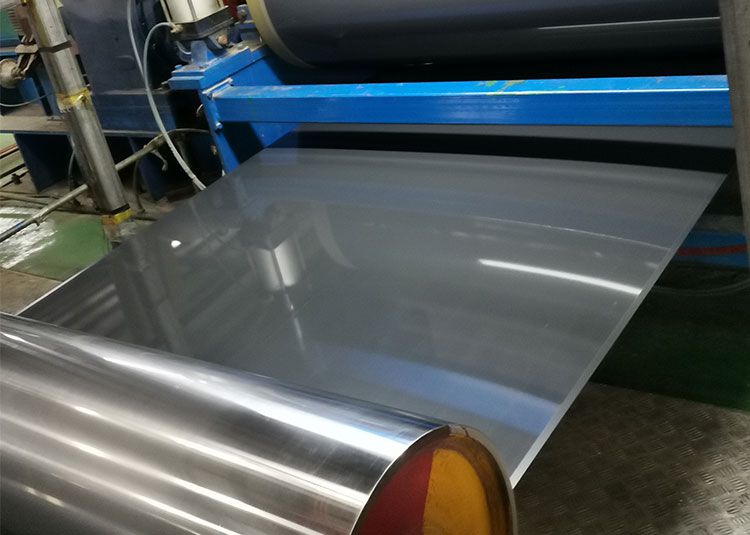

Thickness and tolerances are crucial for flatness and fit-up, especially in panel systems. Surface condition matters because 5005 is often chosen for visible parts; mill finish, brushed finish, or pre-treated surfaces may be requested depending on anodizing or painting plans. Plate width and length affect yield and nesting efficiency. Protective film options can reduce handling marks and scratches-often a hidden cost driver on appearance-critical work.

Mechanically, the typical expectation is moderate strength with good corrosion resistance and good workability. Exact values depend on product form and thickness, so it's best to confirm with the mill test certificate for your batch. As a rule of thumb, H36 will provide noticeably higher strength than annealed (O temper) material, while still allowing forming operations that are common in architectural fabrication.

Implementation standards and common specification references

Customers often ask, "Which standard is this produced to?" The standard depends on region and supply chain, but the most common references for 5005 aluminum plate and sheet include:

ASTM B209 for aluminum and aluminum-alloy sheet and plate is widely used in North America and in international trade. It governs chemical composition, mechanical properties, dimensions, tolerances, and workmanship requirements.

EN 485 series is commonly referenced in Europe for wrought aluminum products, covering mechanical properties and tolerances. Equivalent designations and temper definitions are aligned under EN standards, though purchasing language can vary by supplier.

If anodizing performance is critical, it is also common to discuss surface quality requirements and acceptance criteria beyond the base plate standard, since appearance can be influenced by surface defects, handling, and pretreatment.

Alloy chemistry: why 5005 behaves the way it does

5005 is essentially aluminum with a controlled addition of magnesium, plus tight limits on elements that might interfere with corrosion behavior or surface finishing. Magnesium increases strength while maintaining excellent corrosion resistance, especially in marine or humid atmospheres compared with many other families. The alloy's relatively clean chemistry also supports good anodized appearance.

Below is a commonly cited chemical composition table for Aluminum Alloy 5005. Always treat it as a reference and confirm exact limits per the governing standard and your supplier's test report.

5005 Aluminum Alloy – Typical Chemical Composition (wt.%)

| Element | Content (wt.%) |

|---|---|

| Aluminum (Al) | Remainder |

| Magnesium (Mg) | 0.50–1.10 |

| Silicon (Si) | ≤ 0.30 |

| Iron (Fe) | ≤ 0.70 |

| Copper (Cu) | ≤ 0.20 |

| Manganese (Mn) | ≤ 0.20 |

| Zinc (Zn) | ≤ 0.25 |

| Chromium (Cr) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.20 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

This chemistry is one reason 5005 is often described as an "anodizer-friendly" alloy in practice. Lower copper content, in particular, supports good corrosion resistance and can help avoid some finishing inconsistencies seen in alloys with higher copper levels.

Processing and fabrication notes that influence real-world results

5005 H36 is generally easy to cut with standard fabrication methods. For clean edges on visible parts, shops often prefer sharp tooling and optimized feed rates to reduce burrs. When forming, bend radius guidelines depend on thickness and grain direction; bending with the grain typically requires a larger radius than bending across it. If your design pushes tight bends in thicker plate, it's wise to validate with a forming trial or consider an alternative temper.

Welding is possible using common aluminum welding processes, though the heat-affected zone will locally soften because 5005 relies on work hardening rather than heat treatment. If a welded structure needs uniform strength, designers often account for this by adjusting geometry or using fastening methods where appropriate.

For finishing, 5005 is frequently selected for anodizing and also performs well with paint systems after proper pretreatment. If color consistency across large panel areas is critical, it helps to source material from the same production lot and maintain consistent surface preparation steps.

Why customers choose 5005 H36 over "stronger" alloys

A stronger alloy is not automatically a better panel. In many architectural and aesthetic applications, the decision is driven by how the surface looks after anodizing, how uniformly the sheet or plate behaves during forming, and how confidently it resists corrosion over time. 5005 H36 offers a balanced answer: enough strength to feel solid and resist everyday dents, enough formability to fabricate efficiently, and a surface-friendly chemistry that supports the kind of finish customers actually see.

If you're selecting aluminum plate as if it were only a structural material, 5005 H36 may seem understated. If you're selecting it as a visible, fabricated, long-life product surface, it becomes one of the smartest, most practical choices in the 5xxx family.