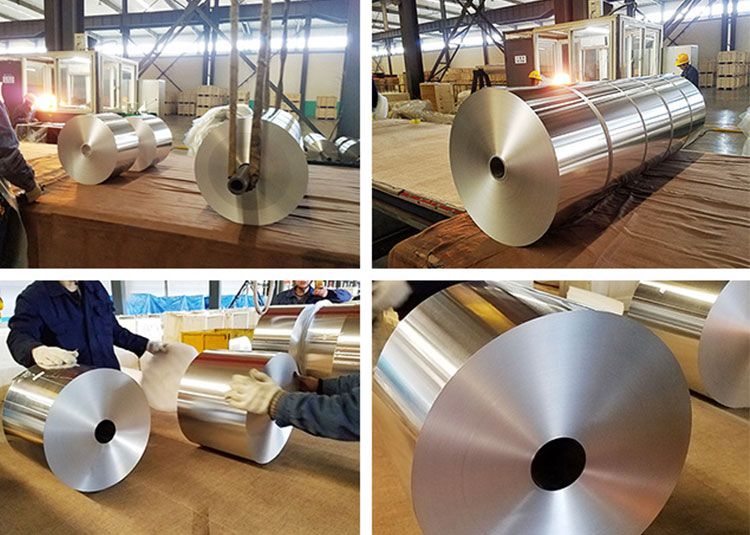

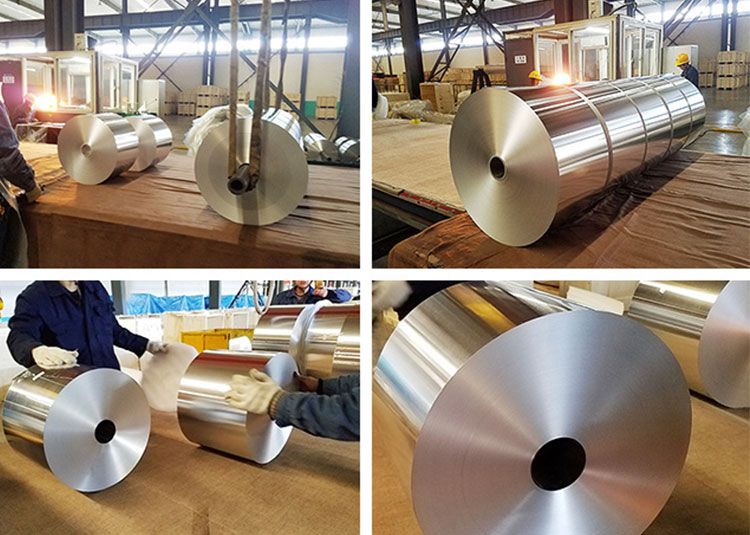

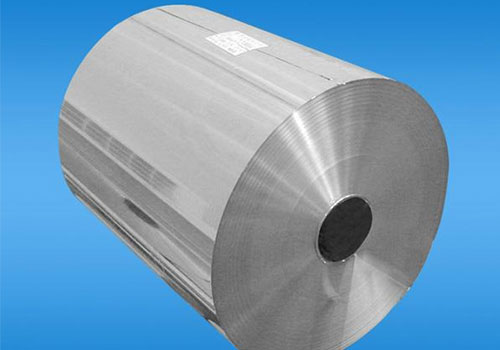

Alloy 8011 H24 Aluminum Foil Jumbo Roll (38 microns) is a versatile, high-performance foil designed for converting into packaging, insulation, sealing, and protective barrier products. Combining the widely used AA 8011 alloy with the H24 temper (strain-hardened and partially annealed), this foil offers an ideal balance of strength, formability, puncture resistance, and barrier performance. At 38 µm thickness, it sits in a "workhorse" range-thick enough for demanding converting processes while remaining flexible, lightweight, and cost-efficient at scale.

This product is typically supplied as a jumbo roll to support high-speed laminating, printing, slitting, and rewinding operations. It is engineered to run smoothly on modern converting lines, providing consistent gauge control, strong mechanical properties, and dependable surface quality for coatings, adhesives, and inks.

Product Snapshot

| Item | Description |

|---|

| Product name | Alloy 8011 H24 Aluminum Foil Jumbo Roll 38 Microns |

| Alloy | AA 8011 |

| Temper | H24 (strain hardened + partially annealed) |

| Thickness | 38 µm (0.038 mm) |

| Supply form | Jumbo roll (for slitting/rewinding/converting) |

| Typical finish options | Bright / matte (single or both sides depending on process) |

| value | Balanced strength + forming + barrier for packaging & industrial converting |

Features That Matter in Converting and Packaging

| Feature | Customer benefit | Why 38 µm helps |

|---|

| Excellent barrier to light, odor, and oxygen | Protects aroma, freshness, and sensitive contents | Thicker gauge improves barrier robustness and handling |

| Strong puncture and tear resistance | Reduces pinholes and damage during processing and transport | 38 µm offers higher puncture resistance vs thinner foils |

| Stable web performance | Runs reliably on laminators, slitters, and rewinders | Better stiffness and flatter web at speed |

| Good formability in H24 temper | Supports embossing, folding, and forming where needed | Balanced hardness reduces cracking risk |

| Surface compatibility for laminating/printing | Bonds well with adhesives and coatings (with proper pretreatment) | Greater thickness tolerates multi-layer converting operations |

Typical Applications

AA 8011 H24 foil at 38 microns is commonly used as a barrier and structural layer in both consumer and industrial products.

| Application area | Typical converted product forms | Performance role |

|---|

| Flexible packaging & laminates | Foil-paper laminates, foil-PE/PET laminates, sachet structures | High barrier + stiffness + print/lamination base |

| Lidding & sealing structures | Heat-seal lids (as part of laminate), peelable sealing webs | Dimensional stability and seal integrity (laminate-dependent) |

| Pharmaceutical & medical packaging | Secondary barrier layers in laminated structures | Light/oxygen barrier, protection and shelf-life support |

| Thermal insulation facings | Foil-faced insulation, reflective facers | Reflectivity + vapor barrier + durability |

| Industrial wrapping and protection | Protective wraps, interleaving, specialty covers | Puncture resistance and shielding |

Note: End-use compliance (food contact, pharma) depends on surface condition, lubricants, cleanliness, and applicable certifications. Always align with destination regulations and converter process requirements.

AA 8011 is an Al-Fe-Si series alloy widely selected for foil due to its excellent processability, consistent strength, and good barrier performance. The H24 temper provides a practical mid-point: stronger than fully annealed foil, but still formable enough for downstream operations that require bending, folding, or moderate forming.

| Parameter | AA 8011 | H24 temper relevance |

|---|

| Strength level | Medium | Helps resist web breaks and handling damage |

| Formability | Good | Partially annealed state improves bend behavior |

| Surface quality | High potential | Suitable for converting when properly controlled |

| Typical use | Packaging/insulation foil | Converting-friendly temper for jumbo roll supply |

Chemical Composition (Typical AA 8011)

The following table reflects typical composition ranges commonly used for AA 8011 foil production. Actual mill certificates may vary by standard and customer specification.

| Element | Typical content (wt. %) |

|---|

| Aluminum (Al) | Balance |

| Iron (Fe) | 0.60–1.00 |

| Silicon (Si) | 0.50–0.90 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.20 |

| Magnesium (Mg) | ≤ 0.05 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.08 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

Technical Specifications: Alloy 8011 H24, 38 µm Jumbo Roll

Specifications can be tailored to different converting lines. The table below shows common supply parameters for customer evaluation and quick referencing.

| Property | Typical value / range | Notes |

|---|

| Thickness | 38 µm ± customer tolerance | Thickness tolerance available per agreement |

| Thickness in mm | 0.038 mm | Useful for design conversions |

| Alloy | AA 8011 | Foil-grade alloy |

| Temper | H24 | Strain hardened + partially annealed |

| Width | Custom (commonly 200–1600 mm) | Subject to mill capability and order |

| Inner core ID | 76 mm / 152 mm | Standard paper/aluminum cores |

| Outer diameter | Custom | Depends on coil weight and handling limits |

| Coil/jumbo roll weight | Custom | Optimized for converter logistics |

| Surface finish | Bright/matte | Often one side brighter due to rolling |

| Pinholes | Controlled | Target depends on end-use requirements |

| Edge condition | Slit edge | Clean edges improve runnability |

| Packaging | Export seaworthy | Moisture protection recommended |

Mechanical & Physical Performance (Typical Ranges)

Mechanical performance depends on process route, gauge control, and exact temper. The following values are typical indicators for 8011 H24 foil at medium gauge.

| Property | Typical range | Test/remarks |

|---|

| Tensile strength (MPa) | 130–170 | Direction-dependent |

| Yield strength (MPa) | 110–150 | Indicative for H24 |

| Elongation (%) | 2–6 | Varies with direction and surface |

| Density (g/cm³) | 2.70 | Aluminum standard |

| Thermal conductivity (W/m·K) | ~235 | Useful for insulation facings |

| Melting range (°C) | ~643–657 | Alloy-dependent |

| Light barrier | Excellent | Essentially opaque at this gauge |

| Water vapor barrier | Excellent | Performance depends on laminate integrity |

Why 38 Microns Is a Practical "Converter Gauge"

| Converting concern | How 38 µm supports it |

|---|

| Web stability at speed | Higher stiffness improves tracking and reduces flutter |

| Slitting and rewinding yield | Reduced edge damage compared with very thin foil |

| Lamination durability | Handles tension and nip pressure reliably |

| Puncture-sensitive designs | Better resistance for industrial and premium packaging |

| Consistency across batches | Mature production gauge with strong process control |

Quality Options Commonly Requested

| Option | Purpose | Typical user |

|---|

| Degreased / low residual oil | Better lamination/printing and cleanliness | Food/pharma and high-end laminates |

| High surface cleanliness | Reduced defects and stronger adhesion | Printing and coating lines |

| Controlled roughness / wettability | Improved bonding with adhesives | Laminators |

| Tight gauge tolerance | Stable performance at high speed | High-output converters |

| Enhanced pinhole control | Better barrier integrity | Packaging applications |

Handling, Storage, and Converting Notes

| Topic | Recommendation |

|---|

| Storage | Keep dry, temperature-stable, and away from corrosive atmospheres |

| Condensation control | Acclimatize rolls before opening to prevent moisture pickup |

| Handling | Use proper clamps/shafts; avoid edge impacts to reduce tears |

| Lamination | Confirm adhesive compatibility and surface treatment needs |

| Slitting | Use sharp knives and correct tension profile to avoid edge waves |

Alloy 8011 H24 Aluminum Foil Jumbo Roll 38 Microns is a converter-ready aluminum foil designed for packaging laminates, insulation facings, and industrial barrier applications. With the proven AA 8011 chemistry and balanced H24 temper, it delivers strong puncture resistance, stable web performance, and excellent barrier protection against light, odor, and oxygen. Supplied as a customizable jumbo roll with controlled thickness, surface quality, and cleanliness options, this 38 µm aluminum foil supports reliable high-speed slitting, printing, and lamination for demanding commercial production.