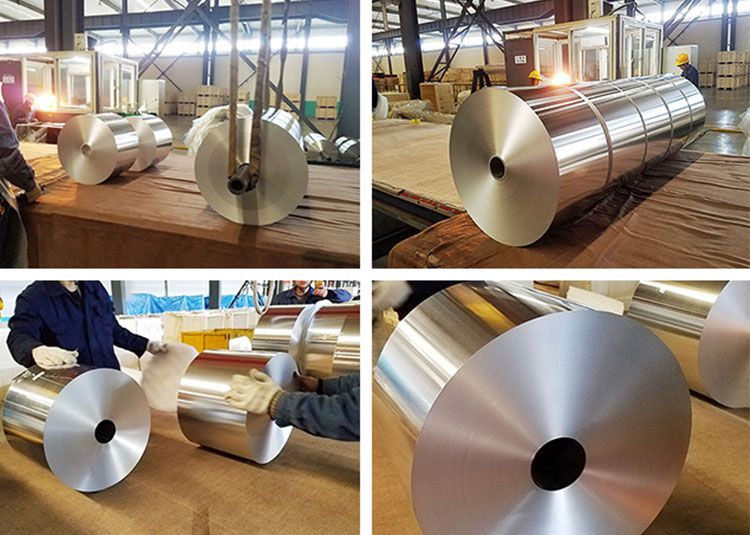

Aluminium foil is an indispensable material in both industrial and domestic applications. Among the various grades of aluminum alloys, Aluminium Foil Alloy 8011 stands out as a premier choice for a myriad of wrapping needs. With growing demands for specialized packing materials, the technical intricacies and properties of the 8011 jumbo roll foil can help businesses maximize efficiency and performance.

Why Choose Aluminium Foil Alloy 8011?

Aluminium Foil Alloy 8011 has become a go-to option for multiple wrapping applications, owing to its lightweight, malleable nature, and excellent barrier properties. This distinctive alloy, produced from high-purity aluminum, demonstrates superior protection against light, air, moisture, and microorganisms—ideal conditions needed to extend the shelf life of food and pharmaceutical products.

Technical Parameters and Characteristics

To fully appreciate the benefits of Aluminium Foil Alloy 8011, it’s essential to examine its specific parameters:

| Property | Specification |

|---|---|

| Alloy Designation | 8011 |

| Thickness Range | 0.006 mm to 0.2 mm |

| Width Range | Up to 1500 mm |

| Tempering | O, H18, H22, H24 |

| Composition (% Maximum) | Si: 0.1, Fe: 0.4, Cu: 0.005 |

| Tensile Strength | 100-500 MPa (varies by temper) |

| Elongation | 2%-12% (varies by temper) |

| Electrical Conductivity | Up to 30% IACS |

Implementation Standards

The manufacture of Aluminium Foil Alloy 8011 abides by various international and national standards to ensure consistency, safety, and performance. Primarily, these standards include:

- ASTM B570: Specification for Aluminium Foil Calibration

- EN 573-3: Chemical composition determination for Aluminium and its alloy

- FDA compliance: Regulations for food packaging

These standards contribute to laboratory-tested performance guarantees, ensuring that the production of 8011 Jumbo Rolls meets global quality assurance norms.

Alloy Tempering

Alloy tempering plays a crucial role in defining the performance of Aluminium Foil Alloy 8011. The distinguishing temper grades include O (annealed), H18, H22, and H24, revealing the soft or hard Alle mark dictates flexibility and application range whetheridable form or structure is key.

- O-Temper: Maximum flexibility for easier wrapping.

- H18 and H22: Higher hardness levels are required for more mechanical and barrier efficacy.

- H24: Pursuing a balance of moderate temper preparing well for any common household or commercial needs.

Chemical Properties

The chemical properties play an essential role in determining aluminum’s corrosion resistance coatings when exposed to ultra-sonic energies photochemical hidden demand pathways.

| Property | Value | Benefits |

|---|---|---|

| Aluminum Oxide Formation | ✔ | Increases refusal rates against contamination |

| Corrosion Resistance | Highly Resistant | Effectiveness at prolonged exposure to humidity |

| Thermal Conductivity | 235 W/m²K | Efficient at reflective heat-grade packaging |

| Yield Strength | Varies by processing | Guarantees deployment success in process reels |