0.5mm Mirror Finish Aluminum Sheet: When Reflectivity Becomes a Functional Surface

A 0.5mm mirror finish aluminum sheet is often described as "decorative," but that label misses its real value. At this thickness, mirror aluminum becomes a precision surface rather than just a shiny material: it reflects light, reduces visual noise in product design, boosts perceived cleanliness in interiors, and-when properly specified-keeps that appearance stable through forming, handling, and service.

From a distinctive viewpoint, think of 0.5mm mirror aluminum as an engineered optical skin. Its job is not only to look bright, but to maintain controlled reflectance after cutting, bending, laminating, and cleaning. That is where alloy choice, temper, coating system, and standards matter as much as the mirror polish itself.

What "Mirror Finish" Really Means at 0.5mm

Mirror finish aluminum sheet is produced through controlled rolling, surface refinement, and often brightening processes to create a highly reflective face. In most real-world projects, mirror performance is measured not just by initial gloss, but by how well the surface resists:

- micro-scratches during fabrication

- haze increase after wiping and cleaning

- oxidation marks at edges

- print-through from packaging films

- distortion caused by bending radii that are too tight for the chosen temper

Because 0.5mm is thin, it responds quickly to forming forces and surface contact-making protective film selection and correct temper selection essential to preserve the "mirror" effect beyond the warehouse.

Typical Parameters for 0.5mm Mirror Finish Aluminum Sheet

Below are common supply parameters used in architectural trims, appliance skins, lighting reflectors, signage, elevator panels, and consumer product shells. Exact values vary by alloy/temper and finishing route, but these ranges help spec the product correctly.

Thickness: 0.50 mm (tolerance commonly per ASTM/EN standard agreements)

Width: typically 1000 mm, 1220 mm, 1250 mm; other widths available by slitting

Length: typically 2000 mm, 2440 mm, 2500 mm; coil supply also common

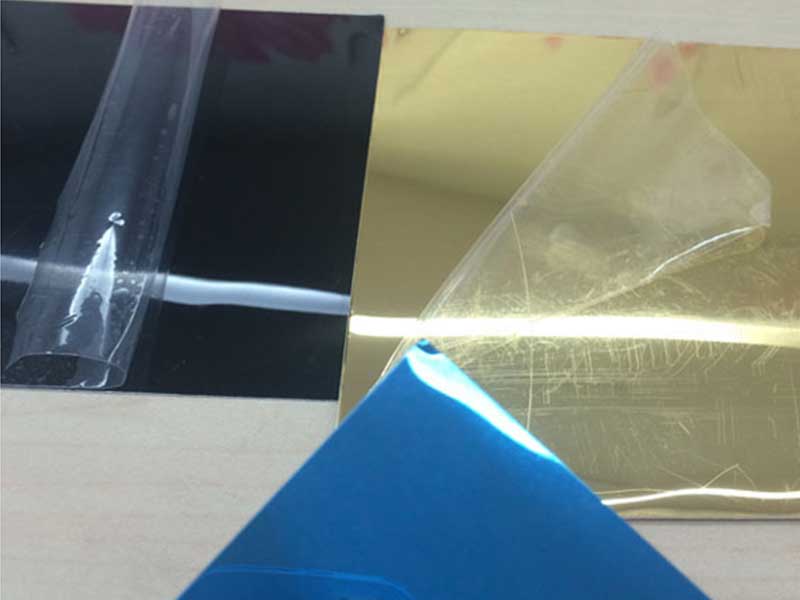

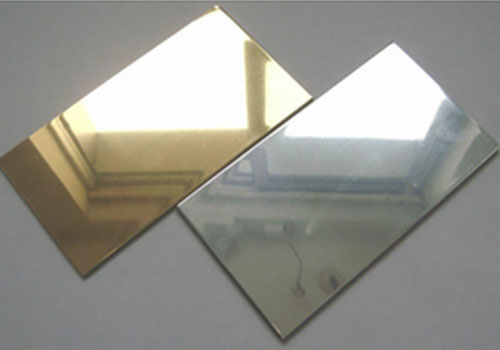

Surface: mirror finish on one side; reverse side may be mill finish or lightly processed

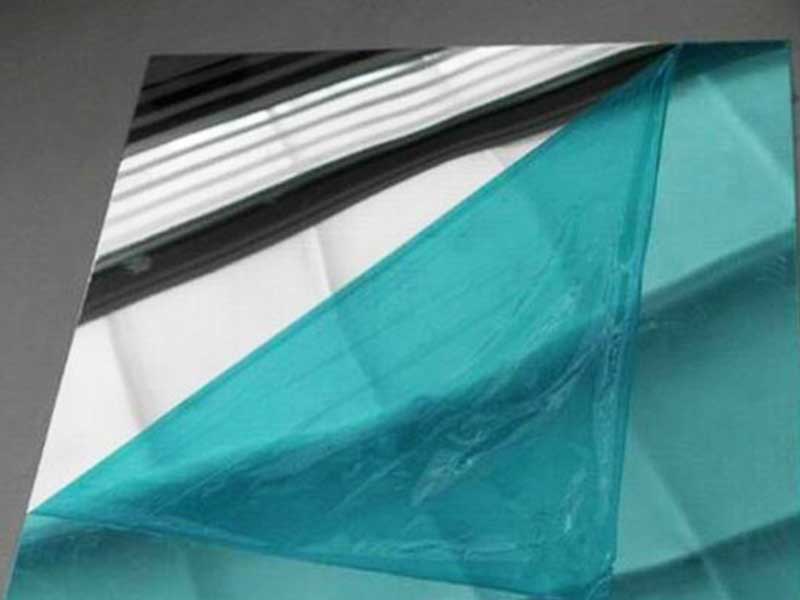

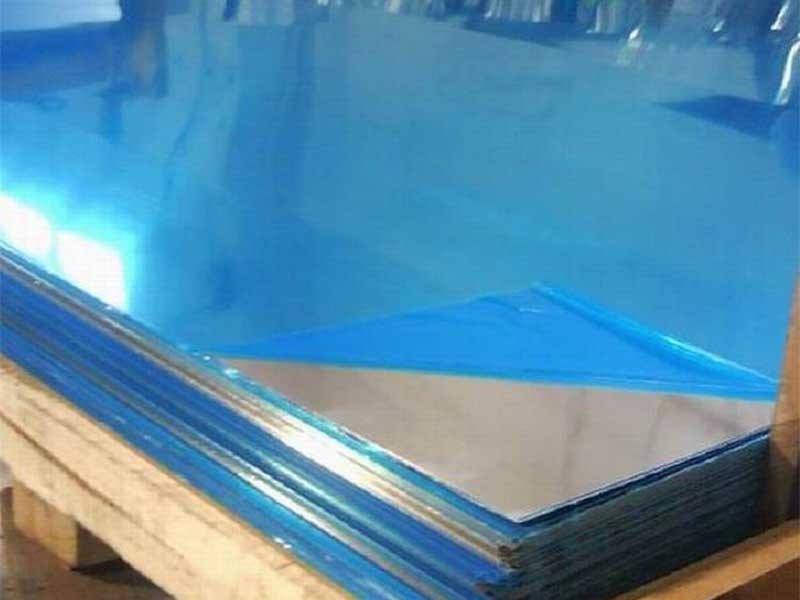

Protective film: PE film (low/medium/high tack); laser film optional for high-end fabrication

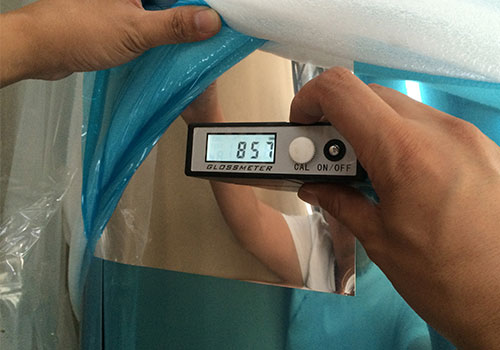

Reflectivity reference: often marketed in the 85%–95% class depending on process and measurement method

Flatness: controlled for visual applications; coil set and waviness requirements should be agreed per order

Edge: trimmed/squared; deburred for safety and cleaner lamination

For projects that treat the sheet as a "reflector," request the reflectance test method up front. Reflectivity numbers can shift depending on whether the measurement is specular, total reflectance, or a defined angle geometry.

Alloy and Temper: Choosing the "Mirror Personality"

Mirror aluminum sheet is frequently produced from 1xxx and 3xxx series alloys because they provide excellent surface quality and consistent anodizing/coating response.

Common alloy options for 0.5mm mirror finish aluminum sheet

- 1050 / 1060 / 1070 / 1100: high purity aluminum for maximum brightness and stable reflectivity; great for lighting reflectors, decorative panels, and applications that prioritize appearance and corrosion resistance

- 3003: improved strength versus 1xxx; good for panels that need more dent resistance while still achieving an attractive mirror finish

- 5052 (select mirror grades): better corrosion resistance in marine/chemical environments and stronger than 3xxx, though achieving ultra-high mirror can be more process-sensitive

Typical tempers you'll see

- O (annealed): best formability; useful for deep drawing or complex bends, but more prone to handling dents and surface impressions

- H14 / H24: balanced strength and formability; a practical choice for trims and panels where light forming is needed

- H16 / H18: higher hardness; better dent resistance and flatness stability, but requires larger bend radii to prevent surface micro-cracking or visible distortion

At 0.5mm, temper influences not only mechanical behavior but also the visual outcome after forming. If the part includes tight bends, choosing a softer temper often preserves mirror continuity better than forcing a hard temper through aggressive tooling.

Implementation Standards and Quality References (How Professionals Specify It)

Mirror finish aluminum sheet is usually purchased against foundational aluminum standards plus project-specific surface agreements.

Commonly referenced standards include:

- ASTM B209 for aluminum and aluminum-alloy sheet and plate (dimensions, tolerances, general requirements)

- EN 485 series for aluminum wrought products (mechanical properties and tolerances in many regions)

- GB/T 3880 for wrought aluminum and aluminum alloy sheets/strips (widely used in Asia)

- RoHS / REACH compliance declarations for electronics, interiors, and consumer products where restricted substances matter

- Coating standards if supplied as coated mirror aluminum, such as PVDF/PE coating performance requirements used in architectural applications (project-specific or regional norms)

Because mirror finish is a surface-driven product, many buyers add practical acceptance language such as allowable scratch level, film type, gloss range, or "no cloudiness under standard inspection lighting." These details often matter more than broad alloy standards when your goal is flawless visual reflection.

Surface Engineering Options: Bare Mirror vs. Coated Mirror

The mirror face can be supplied as:

Bare mirror aluminum

- Highest immediate reflectivity

- Requires careful handling and cleaning discipline

- Suitable for indoor decorative use, reflector components, and laminated applications

Coated mirror aluminum (clear lacquer, PE, or PVDF systems)

- Better fingerprint resistance and easier maintenance

- Improved oxidation and chemical stain resistance

- Often preferred for signage, interior panels, and environments with frequent cleaning

If a project includes strong cleaning agents, cooking fumes, or public-touch exposure, a transparent protective coating can extend the "mirror life" dramatically.

Forming and Fabrication: Protecting the Optical Surface

Working with 0.5mm mirror finish aluminum sheet is like machining a visible lens cover: the surface is the product. Best practice usually includes:

- keeping protective film on during cutting and bending

- using clean tooling and non-marking pads

- specifying bend radius based on temper to reduce surface stress whitening and visual waviness

- separating sheets with soft interleaving for transport

- removing film only after installation or final assembly to minimize micro-abrasion

Even small process decisions-like sliding sheets across a table-can convert a high-grade mirror into a hazy reflection. That's why mirror aluminum is as much about process control as it is about metallurgy.

Chemical Properties: Typical Composition Table (Representative)

The chemistry depends on the chosen alloy. Below are representative composition ranges commonly used in mirror-grade sheet supply. Actual mill test certificates govern final values.

Typical Chemical Composition (wt. %)

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|

| 1050 | ≤0.25 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | ≥99.50 |

| 1060 | ≤0.25 | ≤0.35 | ≤0.05 | ≤0.03 | ≤0.03 | ≤0.05 | ≤0.03 | ≥99.60 |

| 1100 | ≤0.95 (Si+Fe) | included | 0.05–0.20 | ≤0.05 | - | ≤0.10 | - | ≥99.00 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | - | ≤0.10 | - | Rem. |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | ≤0.10 | ≤0.10 | Rem. |

Notes: "Rem." indicates remainder aluminum. Some standards present Fe and Si separately or combined; limits can vary slightly by standard revision and region.

Why 0.5mm Is a Strategic Thickness for Mirror Aluminum

Designers and fabricators repeatedly return to 0.5mm because it sits in a sweet spot:

- thin enough for tight packaging, wrapped edges, and lightweight assemblies

- thick enough to maintain handling integrity compared with ultra-thin foils

- compatible with common coil-processing and lamination lines

- cost-efficient for large-area decorative coverage while still feeling "solid" in installed form

In lighting and display applications, 0.5mm also balances reflectivity with rigidity, helping maintain consistent light distribution without the ripple effect that can appear in thinner material when mounted poorly.

How to Specify 0.5mm Mirror Finish Aluminum Sheet Without Ambiguity

If the goal is to receive mirror aluminum that performs like an optical surface, purchase specs should naturally include:

- alloy and temper, matched to forming requirements

- one-side mirror requirement and back-side condition

- protective film type and adhesion level for your process

- whether the mirror face is bare or clear-coated

- reference standard for dimensions and tolerances (ASTM B209, EN 485, GB/T 3880, or agreed equivalent)

- agreed inspection lighting conditions and acceptable surface criteria

This approach prevents a common mismatch: ordering "mirror aluminum" and receiving a shiny sheet that looks good on the pallet but hazes, scuffs, or distorts once it hits production.

A 0.5mm mirror finish aluminum sheet isn't just a reflective panel-it's a controlled interface between product and environment. It reflects light, signals quality, and withstands the daily physics of touch, cleaning, and assembly. When you treat it as a performance surface and specify alloy, temper, standards, coating, and film correctly, mirror aluminum delivers not only brilliance, but consistency.