When customers talk about “mirror aluminum sheet,” they often picture thick, structural panels. Yet one of the most versatile formats is much thinner: the 0.4 mm mirror aluminum sheet. At this ultra-light gauge, aluminum stops behaving like a heavy plate and starts acting more like a functional skin: reflective, formable, and ready to integrate into modern product designs.

What 0.4 mm Really Means in Practice

A thickness of 0.4 mm sits at the sweet spot between foil and plate. It is:

- Thin enough to be easily bent, rolled, or laminated onto other substrates

- Thick enough to handle basic mechanical loads, resist tearing under normal handling, and maintain surface flatness when installed correctly

In practice, 0.4 mm mirror aluminum is widely used as:

- A visible surface layer for composite panels, signage, and decorative cladding

- An internal reflective layer in lighting fixtures, LED systems, and optical components

- A protective and decorative cover in appliances, electronics, transportation interiors, and exhibition structures

At this gauge, the sheet is rarely used as a standalone structural component. Instead, it behaves as a high-performance, reflective surface bonded, framed, or supported by other materials.

Mirror Finish: How Function Follows Appearance

The defining feature of a mirror aluminum sheet is its surface quality. While it is primarily chosen for aesthetics, the mirror finish also has functional roles:

- Enhanced light reflectivity for energy efficiency in lighting and solar-related applications

- Reduced light absorption, helping equipment stay cooler and extending component life

- Improved visibility, guidance, and safety in reflective signage, interior wayfinding, and display elements

Typical specular reflectivity for high-quality mirror aluminum can range from about 80% to over 90%, depending on the polish grade and coating system. The finish is achieved by precise rolling, polishing, and often chemical or anodic treatment to stabilize gloss and clarity.

Alloys and Tempers: The “Personality” of the Sheet

Behind the mirror surface is the alloy and temper combination, which decides whether the sheet behaves like a forgiving decorative material, a robust industrial skin, or something in between.

Common alloy choices for 0.4 mm mirror aluminum include:

1050 / 1060 / 1100 series

- High-purity, non-heat-treatable alloys

- Excellent formability and high reflectivity

- Well-suited for deep drawing, bending, and complex cosmetic parts

3003 series

- Aluminum-manganese alloy with improved strength

- Good corrosion resistance, especially in humid or mildly corrosive environments

- Often used in building interiors, HVAC covers, and light-industrial applications

5005 or similar 5xxx series

- Aluminum-magnesium alloy with higher strength

- Better corrosion resistance, especially for architectural environments

- Suitable for anodizing with good color uniformity and weather resistance

Typical tempers for 0.4 mm mirror sheet:

O temper (annealed)

- Very soft; ideal for complex forming, embossing, or deep profiles

- Used when the mirror surface must follow tight curves or deep draws

H14 / H16 / H18

- Strain-hardened tempers offering increasing strength and hardness

- H14: medium strength for general forming

- H16 / H18: higher hardness, better flatness, and scratch resistance, but reduced formability

The choice of alloy and temper depends on your balance between three needs: formability, strength, and optical quality. For purely decorative indoor panels, a soft, ultra-bright 1xxx alloy may be ideal. For cladding or architectural details, a 3xxx or 5xxx alloy in a harder temper provides more durability without sacrificing too much mirror effect.

Parameters That Define Performance

When specifying 0.4 mm mirror aluminum sheet, a few parameters matter far more than just thickness and alloy name.

Common technical specifications include:

Thickness tolerance

- Typically ±0.02 mm or better for high-quality rolled coil

- Consistent thickness helps maintain flatness and predictable bending performance

Width and length

- Standard coil widths often range from 600 mm to 1,500 mm or more

- Cut-to-length sheets can be supplied per project needs, such as 1,000 × 2,000 mm or customized sizes

Surface grade

- High-gloss / super-mirror / standard mirror finishes

- Surface defects (scratches, roll marks, pits) tightly controlled under internal and industry standards

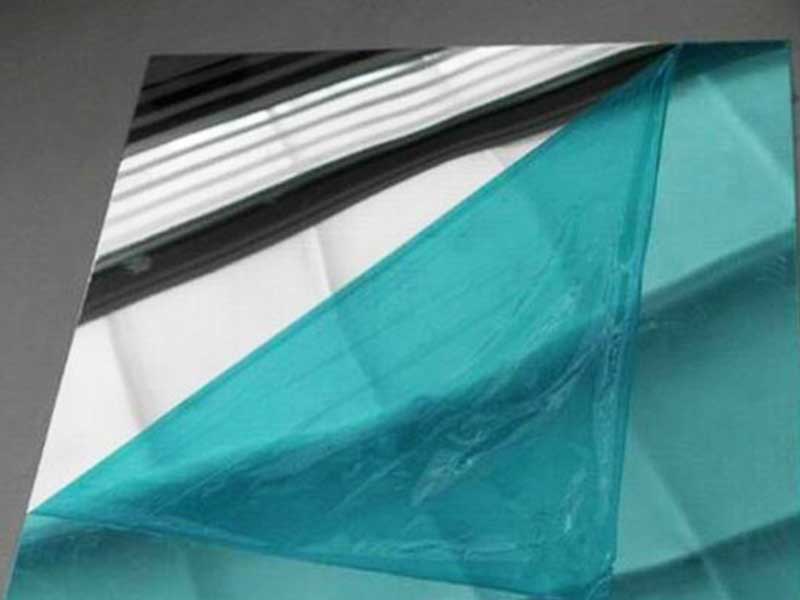

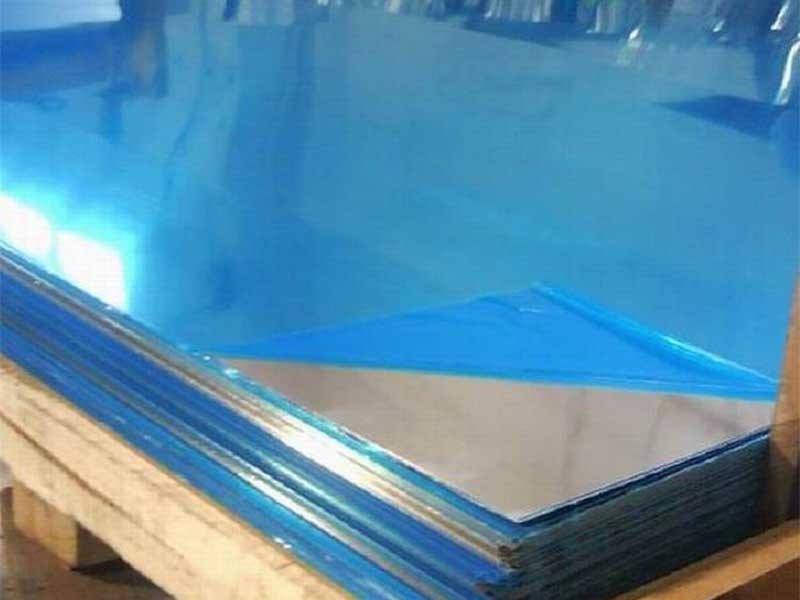

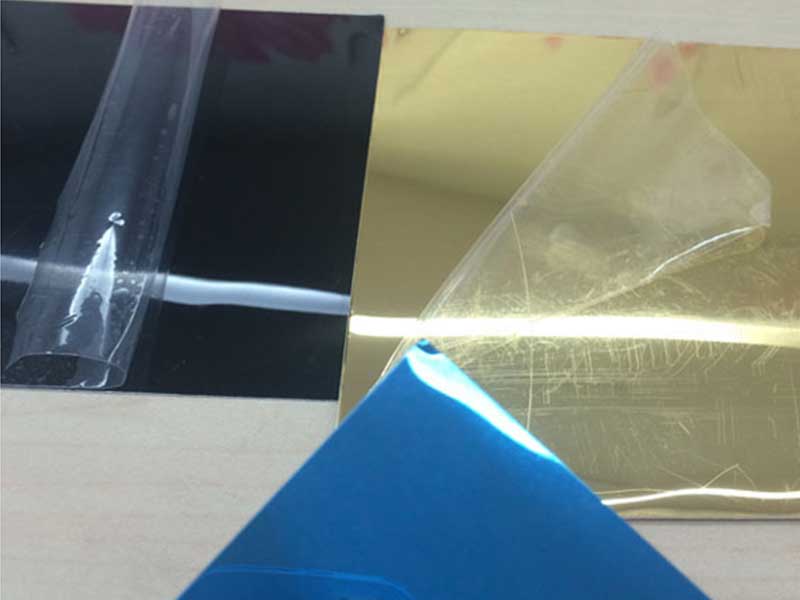

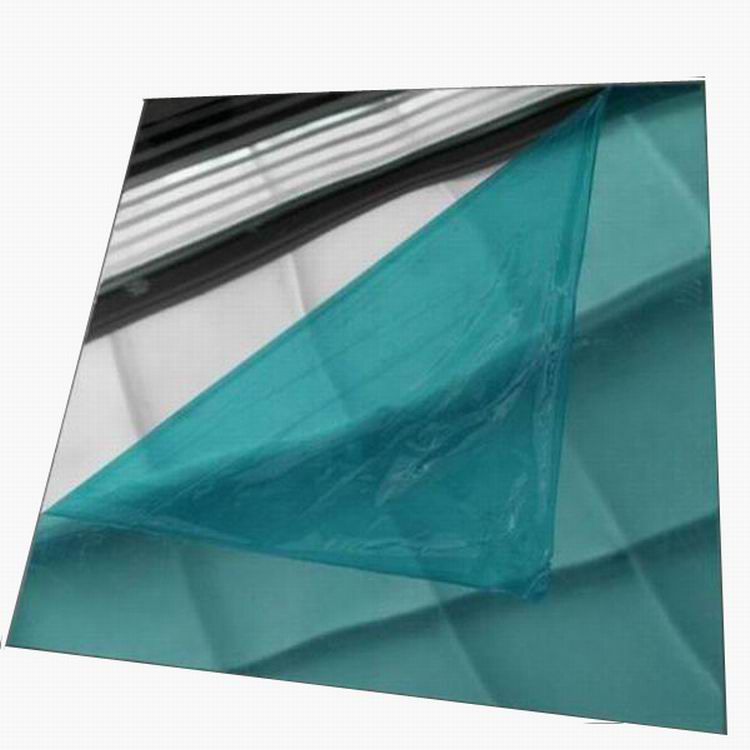

Protective film

- PE or PVC film is commonly applied on one or both sides

- Protects the mirror surface during cutting, bending, and installation

Reflectivity and gloss

- Measured using glossmeters (e.g., at 60° angle) and reflectance meters

- Often specified in terms of specular reflectivity (%) and total reflectance

Implementation Standards and Quality Control

0.4 mm mirror aluminum sheet usually follows recognized standards for base material and mechanical properties, then adds manufacturer-specific surface and optical criteria.

Typical reference standards include:

- EN / ASTM / GB standards for aluminum and aluminum alloy sheet and strip, covering composition, mechanical properties, and tolerances

- ISO-related standards for surface quality, gloss, thickness, and dimensional inspection

- ROHS and REACH compliance for restricted substances, especially important in electronics and export products

In production, quality control often covers:

- Base coil inspection (alloy, temper, flatness, thickness)

- Surface processing (polishing, rolling, anodizing or coating)

- Optical tests (brightness, reflectivity, color consistency)

- Environmental and corrosion testing where relevant (salt spray, humidity, UV resistance for coated or anodized products)

This combination ensures that what arrives on site is not only dimensionally accurate but visually uniform—a crucial point for applications like continuous interior wall panels or long commercial façades.

Chemical Composition: What’s Inside Matters

Below is a representative chemical composition range for a commonly used high-purity mirror alloy such as 1060 (values are typical maximums in weight percent; exact specs vary by standard and supplier):

| Element | Typical Content (wt%) |

|---|---|

| Al | ≥ 99.6 |

| Si | ≤ 0.25 |

| Fe | ≤ 0.35 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.03 |

| Mg | ≤ 0.03 |

| Zn | ≤ 0.05 |

| Ti | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

| Others (total) | ≤ 0.10 |

High aluminum content is the reason 1xxx series mirror sheets achieve superior reflectivity and excellent corrosion resistance, especially for indoor and mild outdoor environments. If higher structural or corrosion performance is required, 3xxx and 5xxx alloys with manganese or magnesium are used, with slightly lower but still very good reflectivity.

Typical Applications Viewed as “Functional Skins”

Thinking of 0.4 mm mirror aluminum sheet as a functional skin helps clarify where it truly excels:

Architectural interiors

- Ceiling panels, column wraps, door and elevator cabs, decorative trims

- Provides a bright, spacious visual effect and easy-to-clean surfaces

Signage and displays

- Retail fixtures, branding panels, exhibition booths, point-of-sale displays

- Lightweight for easy installation, yet visually striking and durable

Lighting and optical systems

- Reflectors in LED fixtures, light boxes, signage backplates, solar concentrators

- High reflectivity maximizes light output and uniformity

Appliance and electronics covers

- Panels for air conditioners, purifiers, Hi-Fi equipment, computer cases, and smart home devices

- Creates a premium appearance while keeping weight and cost under control

Transportation interiors

- Decorative panels in buses, trains, and aviation interiors (when alloy and processing meet the respective standards)

- Combines fire-safe substrate systems with reflective aesthetics in carefully engineered assemblies

In almost all these cases, the 0.4 mm mirror aluminum is not an isolated component. It is bonded, framed, mounted, or laminated—working together with core materials like plastics, honeycomb, MDF, or steel frames.

Practical Considerations for Designers and Buyers

When choosing 0.4 mm mirror aluminum sheet for a project, a few practical points often determine long-term satisfaction:

- Match alloy and temper to forming needs: deep bends and curves demand softer tempers; flat panels and straight folds can use harder tempers for better flatness and scratch resistance.

- Confirm surface protection: always specify protective film type and side (single or double) to avoid damage in fabrication.

- Consider environment: indoors vs outdoors, chemical exposure, humidity, and UV all influence whether you should choose plain-polished, anodized, or coated mirror surfaces.

- Test samples: for visually critical applications, always evaluate real samples under project lighting conditions; even small differences in reflectivity and color tone can be noticeable in a finished installation.

A 0.4 mm mirror aluminum sheet is, essentially, a high-precision reflective membrane engineered to bond, cover, guide light, and beautify. its alloys, tempers, parameters, and standards turns it from a simple “shiny sheet” into a tailored, high-performance component that can elevate both function and design across industries.