1050 Mirror Finish Aluminium Sheet: A Technical Reflection Surface

Looking at 1050 mirror aluminium as a functional optical layer rather than a decorative plate reveals why this alloy has become a default choice for reflectors, light guides and high-end architectural elements.

Why 1050 Alloy Reflects Differently

In strict surface science terms, a perfect crystal with no surface defects would not be a good mirror for industrial use. Real optical performance in reflectors and light panels relies on a carefully engineered pattern of controlled irregularities and layer thicknesses that manage reflectance, scattering and absorptance.

For 1050 mirror aluminium, the “imperfection” is heavily controlled:

- Grain size and orientation after cold rolling and annealing decide how the surface roughens during polishing.

- Oxide thickness built on the aluminium surface decides how light interacts at the interface.

- Residual rolling lines at the nanometer scale can even be used to tune the directional reflectance (anisotropic reflection), which matters in high-efficiency lighting fixtures.

The mirror finish is essentially the final, visible signature of all these controlled “defects” and treatments.

Alloy Temper: How Temper Decides the Mirror’s Personality

The same 1050 alloy can behave like three different materials depending on temper. From a mirror-design point of view, temper is not just hardness; it is a deciding factor in formability, springback, surface stability and even long-term gloss retention.

Common tempers for 1050 mirror finish aluminium sheet include:

O (annealed)

Very soft, excellent deep drawing, spinning and complex forming. Ideal for lamp reflectors that require deep and smooth curvature.

The risk: excessive softness can make the surface more sensitive to handling damage before installation.H14 (half-hard)

Achieved through controlled cold working. Offers a balanced compromise between formability and rigidity. Suitable for moderate bending, roll-forming and paneling where the mirror must retain flatness under its own weight.H18 (full hard)

High strength within the 1xxx series range, limited formability but excellent for flat panels, laminated composites or applications where minimal shape distortion is required.

In practice, mirror-finish manufacturers often optimize the rolling schedule to reach a specific temper that supports polishing quality. If the material is rolled too hard, microscratches from final finishing may not be leveled easily. If it is too soft, the surface can “orange peel” during forming due to grain coarsening. The chosen temper is thus an engineered compromise between optical quality and mechanical behavior during downstream processing.

Typical Parameters of 1050 Mirror Aluminium Sheet

Though each mill controls its own process window, typical technical parameters can be summarized as follows:

- Alloy designation: 1050 (EN AW-1050 / AA 1050)

- Aluminium content: ≥ 99.5%

- Temper: O, H12, H14, H18 and customized intermediate tempers

- Thickness range: about 0.2 mm to 3.0 mm (thinner foils possible on request)

- Width range: up to approximately 1600 mm, depending on mill capacity

- Surface finishes:

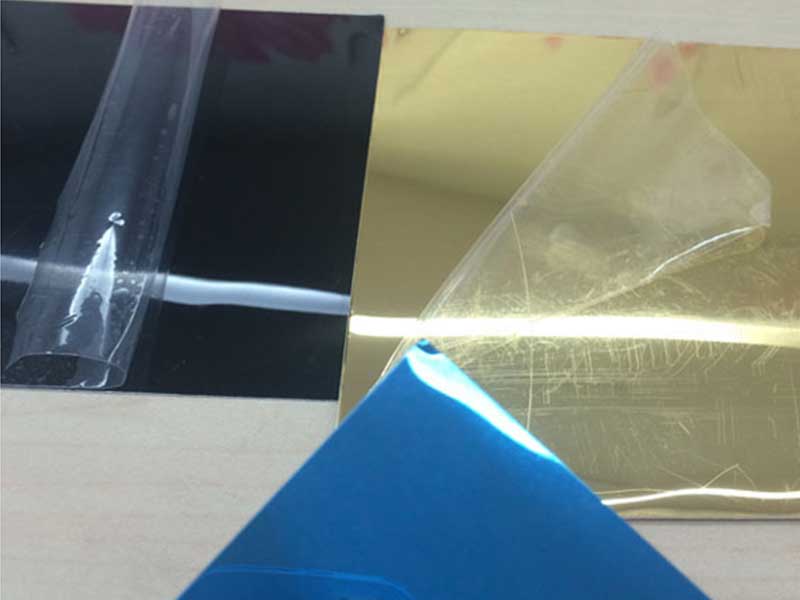

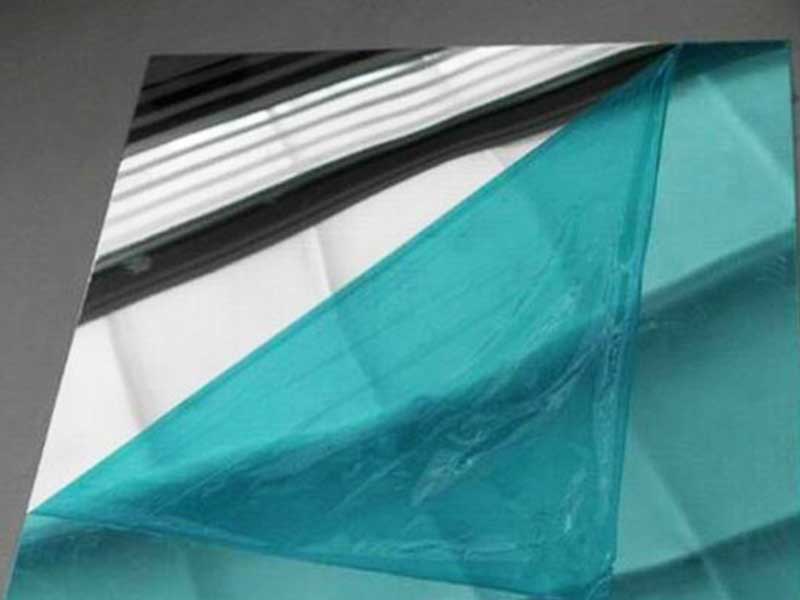

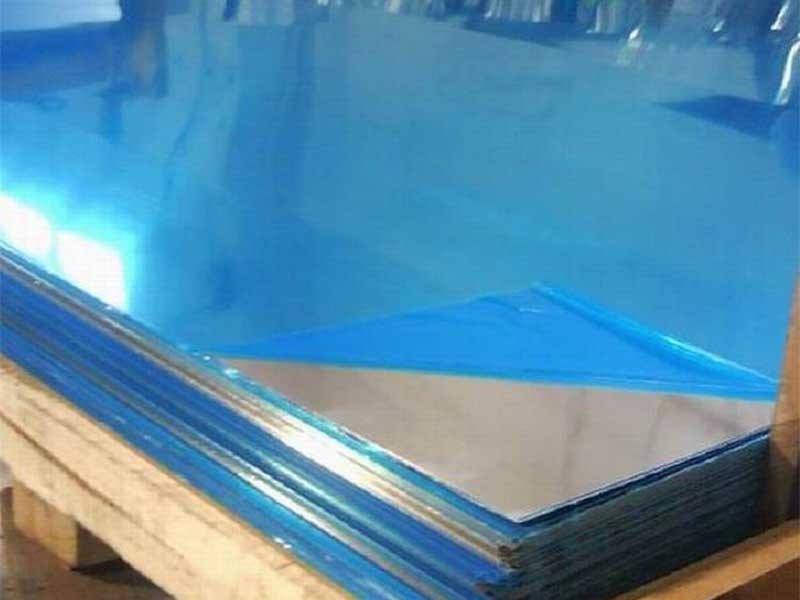

Bright mirror, super mirror (high reflectance), brushed mirror, anodized mirror - Surface protection:

PE protective film (one-side or both-side), laser film for laser cutting applications - Reflectivity levels (typical, visible spectrum):

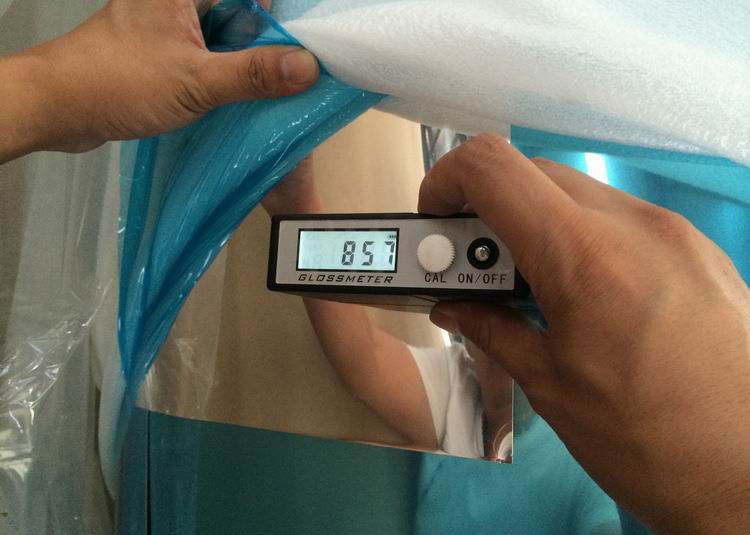

Standard bright: approximately 83–86% total reflectance

High-reflective / super mirror: approximately 86–90% total reflectance (with optimized polishing and/or anodic layers)

These numbers interact. Higher purity and tighter thickness tolerances support higher optical grades by keeping the surface flat and the interference patterns from thickness variations minimal.

Chemical Composition: Purity Framed by Tight Limits

While 1050 is often described simply as “99.5% aluminium,” the remaining fraction is carefully bounded. Those minor elements, though present only in tenths or hundredths of a percent, strongly influence polishability, corrosion behavior and brightness.

Typical chemical composition of 1050 alloy (mass fraction, %):

| Element | Si | Fe | Cu | Mn | Mg | Zn | Ti | Others (each) | Others (total) | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| Max | 0.25 | 0.40 | 0.05 | 0.05 | 0.05 | 0.07 | 0.05 | 0.03 | 0.10 | Balance |

| Min | — | — | — | — | — | — | — | — | — | ≥ 99.50 |

Mechanical and Physical Properties: What Lies Beneath the Shine

Mirror finish does not change the bulk nature of 1050 alloy. It remains a low-strength, highly ductile aluminium suited to applications where formability and reflectance are more important than structural load-bearing capacity.

Typical mechanical properties (reference values, room temperature):

- Tensile strength: about 60–100 MPa (depending on temper)

- Yield strength: about 20–80 MPa (depending on temper)

- Elongation (gauge length proportional): about 10–35% (higher in O temper)

- Elastic modulus: about 69 GPa

- Density: about 2.71 g/cm³

- Thermal conductivity: approximately 220 W/m·K

- Electrical conductivity: approximately 60% IACS or higher

From a mirror-design standpoint, the relatively low modulus and high ductility mean that mechanical support and frame design must be taken seriously for large-area reflectors. A perfectly polished sheet can lose much of its optical advantage if it is not adequately stiffened against vibration, thermal cycling or wind loads.

Implementation Standards and Technical Conformity

Behind the elegant mirror surface is a framework of standards ensuring that each coil and sheet uses an agreed language of quality.

Depending on region and application, 1050 mirror finish aluminium sheet typically aligns to:

- EN standards such as EN 485 (mechanical properties and tolerances for wrought aluminium alloy sheets and plates), EN 573 (chemical composition), and EN 13523 in the context of coated systems.

- ASTM standards like ASTM B209 for aluminium and aluminium-alloy sheet and plate in the US market.

- ISO standards relevant to dimensional tolerances, surface quality inspection methods and anodized coating performance.

Manufacturers of optical-grade mirror sheet often add their own enhanced internal criteria for:

- Peak-to-valley flatness over defined lengths.

- Local and global waviness (which significantly affects the apparent “mirror” in real use).

- Haze and gloss measurements using standardized geometry (for example, 60° gloss meters and hemispherical reflectometers).

These internal standards may be stricter than public norms, because true mirror grade has to satisfy not only industrial tolerances but also human visual sensitivity, which easily detects subtle surface distortions.

Surface Engineering: From Rolled Metal to Optical Layer

The route from cast slab to mirror sheet is a sequence of structure-shaping steps. While every producer has proprietary variants, the general path includes:

- Casting and homogenization, where grain structure and segregation are prepared for subsequent rolling.

- Hot and cold rolling, which refine gauges and strongly influence texture. The crystallographic texture built during rolling affects how the surface responds to polishing.

- Intermediate annealing, which resets or adjusts the grain structure to avoid orange-peel effect and to maintain adequate formability.

- Final cold finishing passes on mirror-precision rolls, which transfer high-gloss patterns to the aluminium surface.

- Optional chemical or electrochemical polishing stages to further reduce micro-roughness.

- Optional anodizing, in which a controlled oxide layer is grown to enhance corrosion resistance, improve reflectance in defined wavelengths, or give a colored reflective surface.

Here, the insight is that mirror reflectance is not just a “polish level.” It is the outcome of a deliberate interaction between alloy purity, rolling texture, lamination of oxide layers and final finishing technology. The difference between ordinary bright aluminium and true “mirror” grade is not a simple step up in polishing time, but a carefully integrated process design.

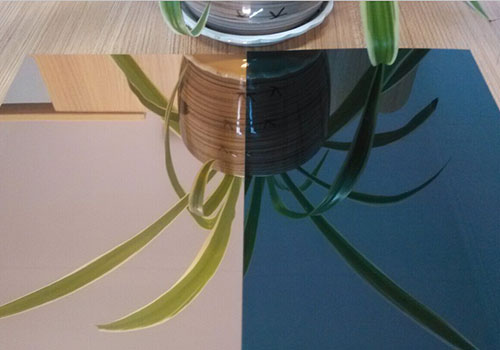

Optical Performance in Real Environments

In application, engineers rarely focus only on initial reflectivity numbers. Long-term stability matters more. For 1050 mirror finish aluminium, that stability is heavily influenced by:

- Natural oxide growth and thickening, which slightly shifts reflective properties over time.

- Surface contamination from dust, moisture, chemicals and industrial atmospheres.

- Mechanical wear from cleaning cycles.

That is why anodized mirror 1050 is widely used where lifetime and cleanability are critical. The anodic layer acts as a protective optical coating: harder than native oxide, better controlled in thickness and generally providing more stable reflectance over years of service.

In LED luminaires, light boxes and solar reflectors, the combination of high initial reflectance, good thermo-optical stability and relatively low mass per square meter makes 1050 mirror sheet an efficient way to control light paths and thermal behavior simultaneously.

Corrosion Behavior: The Invisible Guardian of the Reflective Layer

Chemically, 1050 alloy benefits from its purity in terms of corrosion resistance. Fewer galvanic couples within the matrix, fewer aggressive second phases at grain boundaries, and a very stable native oxide film all contribute to:

- Good resistance to atmospheric corrosion in most urban and rural conditions.

- Solid performance in many indoor industrial environments when not exposed to severe alkalis or chlorides.

- Excellent pairing with anodizing processes, where the oxide becomes thicker, denser and more abrasion resistant.

From a mirror perspective, corrosion is not just about material loss; it is about optical degradation. Pitting, even when extremely shallow, causes local scattering and visible defects. Thus, in coastal or chemically aggressive environments, anodized or coated mirror 1050 usually replaces bare mirror for long-term aesthetics and optical functionality.

Forming and Fabrication: Designing with Light and Metal Together

The forming behavior of 1050 mirror finish sheet is often discussed purely in terms of bend radius and drawability. From the standpoint of a lighting designer or an architect, there is a second layer: how the forming process will distort the mirror image.

Important considerations include:

- Grain orientation: bending parallel vs. transverse to the rolling direction can affect likelihood of surface strain markings.

- Bend radius: larger radii help preserve surface integrity and avoid visible tensile marks on the tension side of the bend.

- Post-forming stress relief: low-temperature treatments can mitigate elastic springback and warping that disturb optical alignment in complex assemblies.

For deep-drawn lamp reflectors, O-temper 1050 mirror often provides the best outcome, allowing complex shapes without cracking while still preserving a clean, continuous reflective surface. For flat or shallow-formed architectural panels, a half-hard temper maintains better resistance to “oil-canning” and surface waviness.

A Functional Mirror, Not Just a Shiny Sheet

1050 mirror finish aluminium sheet is best understood as a carefully controlled optical interface built on a nearly pure aluminium substrate. Its reflective performance is not a cosmetic afterthought; it is a functional property that emerges from:

- High aluminium content and tightly limited impurity levels.

- Precisely tuned temper states that balance formability with rigidity and surface stability.

- Integrated rolling, polishing and anodizing steps that engineer the micro-topography and oxide structure.

- Conformity to international standards, refined by manufacturer-specific criteria for gloss, haze, flatness and surface integrity.

By treating 1050 mirror aluminium as an engineered light-management material rather than just “bright metal,” designers can better choose temper, thickness, surface treatment and fabrication routes that preserve both its optical capability and its visual impact over the full lifetime of the product.