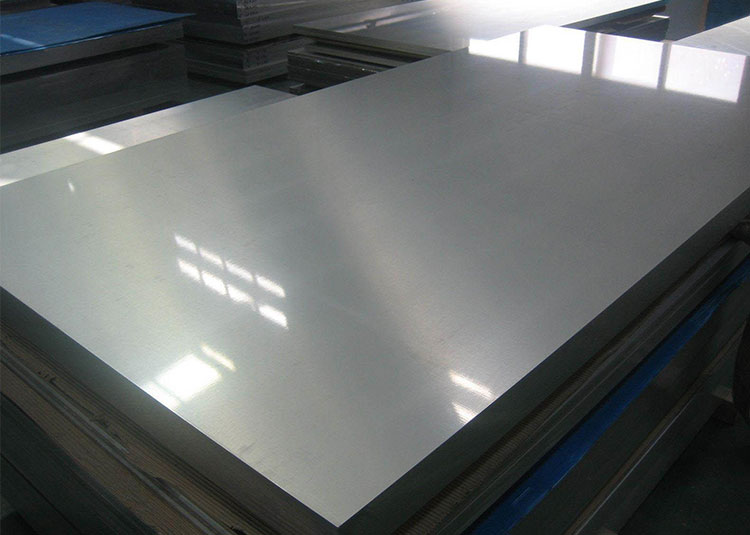

Marine and offshore engineering aluminum sheet plate is engineered specifically for harsh saltwater environments, offering a unique balance of strength, corrosion resistance, weldability, and weight savings. It is a preferred material for shipyards, offshore platform builders, and marine equipment manufacturers who need reliable performance with long service life and low maintenance.

High-strength marine and offshore engineering aluminum sheet plate for shipbuilding, offshore platforms, deck structures, and marine equipment. Excellent seawater corrosion resistance, low weight, easy fabrication, and stable mechanical properties. Available in grades 5083, 5086, 5454, 5052, 6061, and 6082, with a wide range of tempers, thicknesses, and widths for demanding marine environments.

Features of Marine Aluminum Sheet Plate

Core Performance Advantages

- High resistance to seawater and industrial atmospheres

- Excellent strength-to-weight ratio

- Good weldability with minimal loss of properties in the heat-affected zone

- Stable performance in low and medium temperatures

- Non-magnetic and spark-free, enhancing safety in offshore environments

- Easy forming, bending, and cutting for complex marine structures

Typical Marine Alloys

Marine aluminum sheet plate commonly uses Al-Mg and Al-Mg-Si alloys. These alloys combine corrosion resistance with structural strength and are approved by major classification societies (such as DNV, ABS, LR, BV, CCS) for marine service.

| Alloy Series | Typical Alloy | Alloy Type | Strengths | Typical Use Area |

|---|---|---|---|---|

| 5xxx | 5083 | Non-heat-treatable Al-Mg | High corrosion resistance, good welding | Hull plating, decks, side shell |

| 5xxx | 5086 | Non-heat-treatable Al-Mg | Good strength in welded condition | Superstructures, small craft hulls |

| 5xxx | 5454 | Non-heat-treatable Al-Mg | Better temp resistance vs 5052 | Tanks, piping, superstructure plating |

| 5xxx | 5052 | Non-heat-treatable Al-Mg | Excellent formability | Interior panels, fairings, cabinets |

| 6xxx | 6061 | Heat-treatable Al-Mg-Si | High structural strength | Racks, frames, machined marine parts |

| 6xxx | 6082 | Heat-treatable Al-Mg-Si | Very good strength and toughness | Offshore structures, heavy-duty supports |

Chemical Composition (Typical Values)

Values below are typical ranges in weight percent. Exact composition follows related EN, ASTM, or GB standards and can be supplied upon request.

5xxx Marine Alloys

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Others Each (%) | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|---|

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.40–1.00 | 4.00–4.90 | 0.05–0.25 | ≤0.25 | ≤0.15 | ≤0.05 | Remainder |

| 5086 | ≤0.40 | ≤0.50 | ≤0.10 | 0.20–0.70 | 3.50–4.50 | ≤0.25 | ≤0.25 | ≤0.15 | ≤0.05 | Remainder |

| 5454 | ≤0.25 | ≤0.40 | ≤0.10 | 0.50–1.00 | 2.40–3.00 | 0.05–0.20 | ≤0.25 | ≤0.20 | ≤0.05 | Remainder |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.20–2.80 | 0.15–0.35 | ≤0.10 | ≤0.10 | ≤0.05 | Remainder |

6xxx Marine Alloys

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Others Each (%) | Al (Balance) |

|---|---|---|---|---|---|---|---|---|---|---|

| 6061 | 0.40–0.80 | ≤0.70 | ≤0.40 | ≤0.15 | 0.80–1.20 | 0.04–0.35 | ≤0.25 | ≤0.15 | ≤0.05 | Remainder |

| 6082 | 0.70–1.30 | ≤0.50 | ≤0.10 | 0.40–1.00 | 0.60–1.20 | ≤0.25 | ≤0.20 | ≤0.10 | ≤0.05 | Remainder |

Typical Tempers and Mechanical Properties

Marine aluminum sheet plate is supplied in tempers optimized for strength, corrosion resistance, and formability. The most used tempers are H116, H321, H32, O for 5xxx series, and T6/T651 for 6xxx series.

Common Tempers

| Alloy | Common Marine Tempers | Description |

|---|---|---|

| 5083 | O, H111, H116, H321 | High corrosion resistance, hull & deck use |

| 5086 | O, H111, H116, H32 | Good strength in welded structures |

| 5454 | O, H111, H32 | Higher temperature service, tanks |

| 5052 | O, H32, H34 | Excellent formability, interior structures |

| 6061 | O, T4, T6, T651 | High strength, machined and structural use |

| 6082 | O, T6, T651 | Heavy-duty structural and offshore frames |

Typical Mechanical Properties at Room Temperature

Values below are indicative and may vary slightly by standard, thickness, and temper.

| Alloy–Temper | Tensile Strength Rm (MPa) | Yield Strength Rp0.2 (MPa) | Elongation A50 (%) | Brinell Hardness HBW |

|---|---|---|---|---|

| 5083-H116 | 305–345 | 215–240 | 10–14 | ~95–100 |

| 5083-H321 | 295–335 | 215–240 | 12–16 | ~90–100 |

| 5086-H116 | 275–315 | 190–230 | 10–14 | ~80–90 |

| 5454-H32 | 220–260 | 170–215 | 12–18 | ~65–75 |

| 5052-H32 | 215–265 | 160–210 | 7–14 | ~60–70 |

| 6061-T6 | 260–310 | 240–275 | 8–12 | ~90–95 |

| 6082-T6 | 290–340 | 250–300 | 8–12 | ~95–105 |

Corrosion Resistance and Surface Performance

Marine aluminum sheet plate is engineered to perform in direct seawater contact and splash zones, where chloride-induced corrosion is severe.

| Property | 5xxx Alloys (5083/5086) | 6xxx Alloys (6061/6082) |

|---|---|---|

| Seawater Corrosion | Excellent | Good (preferably coated/anodized) |

| Stress Corrosion Cracking | Very good in marine tempers | Good with proper design |

| Pitting Resistance | High due to Mg content | Moderate to good |

| Anodizing Response | Good, matte or decorative finish | Very good, hard and decorative |

| Galvanic Compatibility | Good with similar Al alloys | Requires isolation from Cu/steel |

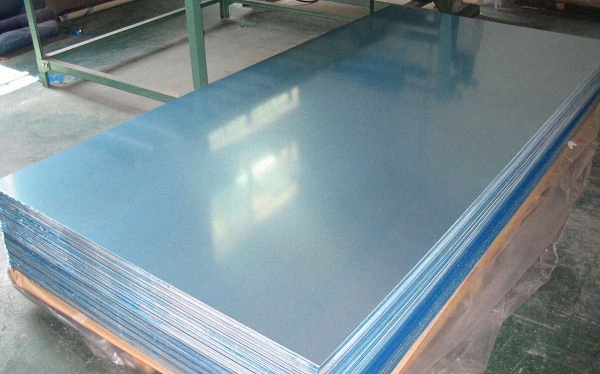

Dimensional Range and Tolerances

Dimensions can be customized to project drawings. The following ranges are typical for marine and offshore aluminum sheet plate.

| Parameter | Typical Range |

|---|---|

| Thickness (sheet) | 0.8 – 6.0 mm |

| Thickness (plate) | 6 – 150 mm (thicker on request) |

| Width | 1000 – 2600 mm |

| Length | 2000 – 12000 mm |

| Flatness | As per EN / ASTM / ship-class rules |

| Edge Condition | Mill edge, saw-cut, or machined |

Tight tolerances on thickness and flatness support automated welding and panel fabrication, reducing rework and fit-up issues in shipyards.

Processing and Fabrication Characteristics

Marine and offshore aluminum sheet plate is designed to integrate smoothly into existing fabrication lines.

| Process | Performance Notes |

|---|---|

| Welding | Excellent with MIG/TIG; minimal strength loss in 5xxx |

| Cutting | Compatible with plasma, waterjet, laser, and mechanical saws |

| Forming/Bending | Good cold formability, especially in O and H111 tempers |

| Machining | Good machinability for 6xxx; adequate for 5xxx with sharp tools |

| Surface Treatment | Suitable for anodizing, painting, and anti-fouling systems |

To maintain corrosion resistance, use appropriate filler wires (such as 5183, 5356) and avoid contamination from carbon steel tools and fixtures.

Main Applications in Marine and Offshore Engineering

Marine aluminum sheet plate supports a wide spectrum of marine and offshore structures where weight, durability, and safety are critical.

| Application Area | Typical Uses | Preferred Alloys |

|---|---|---|

| Shipbuilding – Hull | Side shell, bottom plates, bow/stern structures | 5083, 5086 |

| Shipbuilding – Deck & Superstructure | Weather decks, accommodation decks, bridges, wheelhouses | 5083, 5454, 5052 |

| Offshore Platforms | Helidecks, walkways, handrails, living quarters, escape routes | 5083, 6082, 6061 |

| Marine Outfitting | Bulkheads, doors, hatches, stairways, cable trays | 5052, 5083 |

| Storage & Process Tanks | Potable water, fuel, chemical and LNG containment | 5083, 5454 |

| High-Speed Craft & Ferries | Hull shell, deck structures, internal framing | 5083, 5086 |

| Port & Coastal Structures | Gangways, pontoons, floating docks, ladders | 5083, 6082 |

| Marine Equipment | Winch bases, cranes, davits, racks, skids | 6061, 6082, 5083 |

The low density of aluminum—about one-third that of steel—reduces overall vessel weight, enabling higher payload, better fuel efficiency, and improved stability, especially important for high-speed craft and multi-deck ships.

Benefits Compared to Traditional Steels

| Attribute | Marine Aluminum Sheet Plate | Marine-Grade Steel |

|---|---|---|

| Density | ~2.7 g/cm³ | ~7.8 g/cm³ |

| Corrosion Protection | Intrinsic seawater resistance, optional coating | Requires painting and cathodic protection |

| Maintenance | Lower; less rust, less repainting | Higher; frequent inspection and recoating |

| Fabrication Speed | High; easy cutting and welding | High, but more grinding and surface prep |

| Lifecycle Cost | Lower in many marine applications | Higher due to coating and corrosion repair |

Quality, Certification, and Traceability

Marine and offshore projects demand consistent quality and full documentation. Marine aluminum sheet plate can be supplied to meet:

- International material standards (such as EN, ASTM, ISO, GB)

- Classification society approvals (such as DNV, ABS, LR, BV, CCS)

- Mill test certificates (MTC) with heat number traceability

- Ultrasonic or other non-destructive testing for critical plates

| Quality Item | Available Options |

|---|---|

| Inspection | Visual, dimensional, ultrasonic, hardness tests |

| Documentation | EN 10204 3.1/3.2, classification approvals |

| Marking | Heat number, alloy, temper, dimensions, standard |

| Packaging | Seaworthy pallets, interleaf paper, film wrap |