Features and scope of application:

2A11 aluminum alloy is the earliest hard aluminum, generally called standard hard aluminum, with medium strength. It has good plasticity in annealing, quenching and hot state. It can be heat-treated and strengthened. It can be used in quenching and natural aging conditions. The weldability is good, and there is a tendency to crack when performing gas welding and argon arc welding; the cutting is good in the quenching aging state and is poor in the annealing state.

chemical composition:

| Al | Si | Cu | Mg | Zn | Mn | Ti | Ni | Fe | Fe + Ni |

| balance | ≤0.7 | 3.8 - 4.8 | 0.40~0.8 | ≤ 0.30 | 0.40 - 0.8 | ≤ 0.15 | ≤ 0.10 | 0-0.7 | 0-0.7 |

Note: single: ≤ 0.05; total: ≤ 0.10

Mechanical properties:

Tensile strength σb (MPA): ≥370

Yield strength σ0.2 (MPA): ≥215

Elongation δ5 (%): ≥12 Note: Longitudinal mechanical properties of bar at room temperature

Heat treatment specification:

1) Homogenization annealing: heating 480 ~ 495 ° C; holding 12 ~ 14h; furnace cooling.

2) Complete annealing: heating 390 ~ 430 ° C; holding time 30 ~ 120min; air cooling.

3) Rapid annealing: heating 350 ~ 370 ° C; holding time is 30 ~ 120min; air cooling.

4) Quenching and aging: quenching 495 ~ 510 ° C, water cooling; artificial aging 155 ~ 165 ° C, 6 ~ 10h, air cooling; natural aging: room temperature 96h.

Related Application

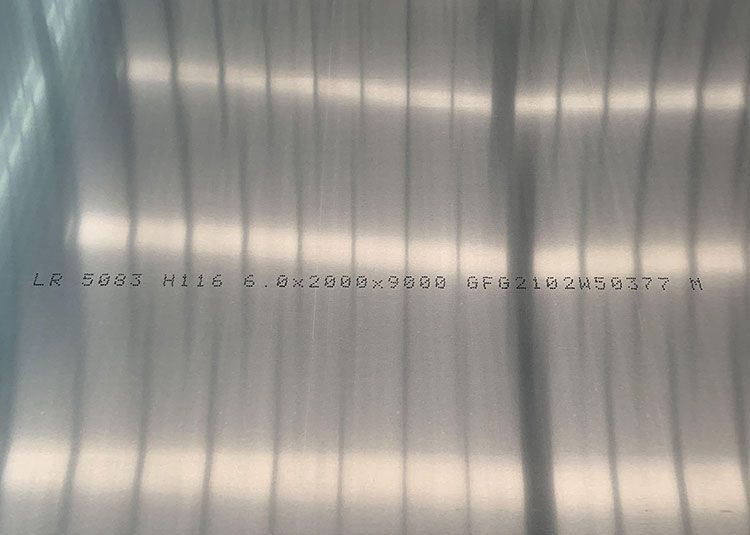

Aluminum Sheet Coils For Trailers And Tankers

3003-H16 Aluminum Sheet, 5052-H32 Aluminum Sheet, 5083-O H111 Aluminum Sheet, 5454 Aluminum Sheet

Aluminum Sheet For Autobody

5052-O aluminum sheet, 5182-O aluminum sheet, 5754-O aluminum sheet, 6016-T4 aluminum sheet

Related Blog

High-end 2A11 Aviation Aluminum Plate for Aircraft Bolts