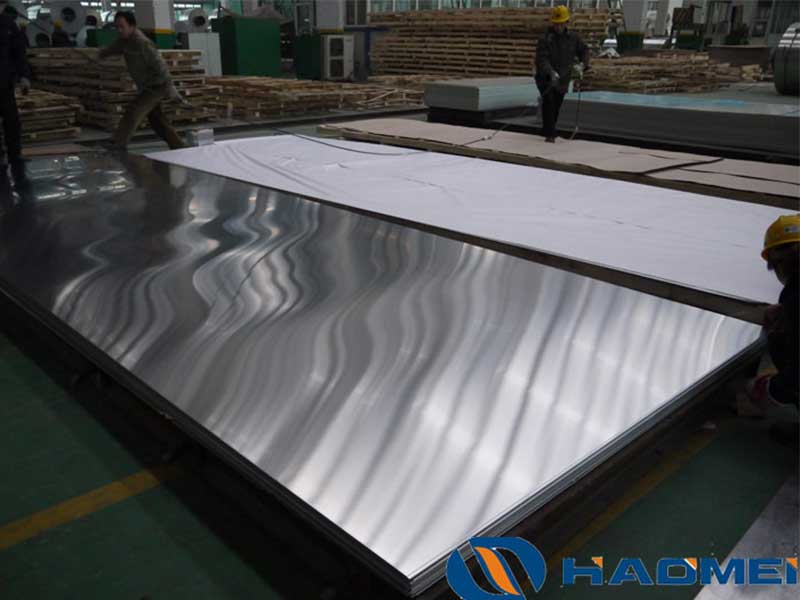

Aluminum sheet in 1mm, 2mm, and 5mm thicknesses is widely used across construction, transportation, packaging, and manufacturing. These thicknesses cover most light to medium-duty structural and decorative requirements, balancing strength, weight, and formability.

| Parameter | 1mm Sheet | 2mm Sheet | 5mm Sheet |

|---|---|---|---|

| Typical Alloy Families | 1xxx, 3xxx, 5xxx, 6xxx | 1xxx, 3xxx, 5xxx, 6xxx | 5xxx, 6xxx |

| Typical Tempers | O, H14, H24, T4 | H14, H24, H32, T4, T6 | H116, H321, T6 |

| Application Type | Lightweight, non‑structural | General purpose, semi‑structural | Structural, load‑bearing |

| Formability | Excellent | Very good | Moderate (depends on alloy/temper) |

| Relative Weight per m² | ~2.7 kg | ~5.4 kg | ~13.5 kg |

| Preferred Uses | Cladding, covers, signs | Panels, enclosures, trays | Base plates, frames, tooling |

Note: Actual alloys and tempers depend on supplier and project requirements; values are indicative.

2. Typical Alloys and Chemical Composition

Common alloy choices for these thicknesses include 1100, 3003, 5052, and 6061. The table below shows typical composition ranges (wt.%):

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al (approx.) |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤0.95* | ≤0.95* | 0.05–0.20 | ≤0.05 | ≤0.05 | – | ≤0.10 | – | ≥99.00 |

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | – | – | ≤0.10 | – | Balance |

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | 0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.03 | Balance |

| 6061 | 0.40–0.80 | 0.70 | 0.15–0.40 | 0.15 | 0.80–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance |

*Combined Si + Fe.

Typical thickness–alloy pairing:

- 1mm: 1100, 3003, 5052 (for higher corrosion resistance), 6061 (when extra strength is needed).

- 2mm: 3003, 5052, 6061 (good balance of strength and workability).

- 5mm: 5052-H32/H116 and 6061-T6 for structural and marine/industrial applications.

3. Mechanical Properties (Representative Values)

Actual values vary by alloy, temper, and thickness. Below are typical mechanical properties for common choices:

| Alloy–Temper | Thickness | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Brinell Hardness (HB) |

|---|---|---|---|---|---|

| 3003-H14 | 1–2mm | 130–180 | 110–145 | 5–10 | ~40–50 |

| 5052-H32 | 1–5mm | 210–260 | 130–180 | 7–12 | ~60–70 |

| 6061-T6 | 1–5mm | 260–320 | 240–280 | 8–12 | ~90–100 |

Implications by thickness:

- 1mm: High ductility; easy to bend, roll, cut; suitable for deep drawing (depending on alloy).

- 2mm: Stronger panels; good stiffness; still readily formable by press brake and roll forming.

- 5mm: Significantly stiffer and stronger; often used for base plates, frames, and machined components.

4. Physical & Performance Characteristics

| Property | Typical Value (Al Alloys) | Benefit |

|---|---|---|

| Density | ~2.70 g/cm³ | ~1/3 the weight of steel |

| Thermal Conductivity | 120–180 W/m·K | Effective heat spreading and dissipation |

| Electrical Conductivity | 30–40 MS/m (depending on alloy) | Useful for bus bars, grounding plates |

| Coefficient of Expansion | ~23 × 10⁻⁶ /K | Predictable expansion for design |

| Melting Range | ~580–660°C | Not suitable for high‑temperature structures |

| Corrosion Resistance | Medium to excellent (alloy‑dependent) | Suitable for outdoor and marine environments |

| Surface Reflectivity | ~80–90% (visible) | Good for reflectors, architectural cladding |

5. Dimensional & Technical Specifications

Typical supply range for 1mm, 2mm, and 5mm aluminum sheets:

5.1 Standard Dimensions

| Parameter | Typical Options |

|---|---|

| Thickness | 1.0mm, 2.0mm, 5.0mm (tolerance per standard) |

| Width | 1000mm, 1200mm, 1250mm, 1500mm (others on request) |

| Length | 2000mm, 2440mm, 3000mm, 4000mm (custom cut) |

| Surface Finish | Mill finish, brushed, embossed, anodized, coated (PE/PVDF) |

| Edge Condition | Mill edge, slit edge |

| Standards | ASTM B209, EN 485, GB/T 3190 (or equivalent) |

5.2 Thickness Tolerance (Typical, as per common standards)

| Nominal Thickness | Typical Tolerance (mm) |

|---|---|

| 1.0mm | ±0.04 |

| 2.0mm | ±0.06 |

| 5.0mm | ±0.10 |

Exact tolerances depend on alloy, temper, and applicable standard.

6. Application Focus by Thickness

6.1 1mm Aluminum Sheet

Features:

- Very lightweight and easy to handle

- High formability and excellent bendability

- Compatible with stamping, laser cutting, and forming

Typical Applications:

- Architectural: Interior wall panels, decorative cladding, column wraps

- Signage & Displays: Advertising boards, license plates, face panels

- HVAC & Appliances: Ducting, housings, covers, decorative trims

- Packaging & Enclosures: Light protective covers, electronic casings, battery shells (depending on alloy)

Why choose 1mm:

When weight and formability are more critical than structural strength, and you need fast, economical fabrication.

6.2 2mm Aluminum Sheet

Features:

- Good stiffness while remaining formable

- Balanced weight–strength ratio

- Suitable for both flat panels and bent profiles

Typical Applications:

- Building & Construction: Exterior facades, curtain wall panels, balcony paneling, soffits

- Transportation: Interior panels in buses, trains, trucks; floor linings with reinforcing profiles

- Industrial: Machine guards, equipment covers, control panel fronts, trays

- Furniture & Fixtures: Cabinet fronts, retail shelving panels, partitions

Why choose 2mm:

For general-purpose structural panels where you need higher rigidity than 1mm but still want relatively easy bending and lower weight than thicker plates.

6.3 5mm Aluminum Sheet

Features:

- High stiffness and excellent load-bearing capacity

- Suitable for machining, drilling, and tapping

- Often used in higher-strength alloys (5052, 6061)

Typical Applications:

- Structural & Mechanical: Frames, base plates, machine tables, support brackets

- Marine & Outdoor: Boat hull sections, deck plates, ramps, marine structural parts (5052, 5083)

- Transportation: Truck bodies, toolboxes, floor panels with anti-slip patterns (e.g., checker plate)

- Engineering & Tooling: Jigs, fixtures, mounting plates, precision-machined components (6061-T6)

Why choose 5mm:

When structural stability, impact resistance, and long-term durability under load are primary design criteria.

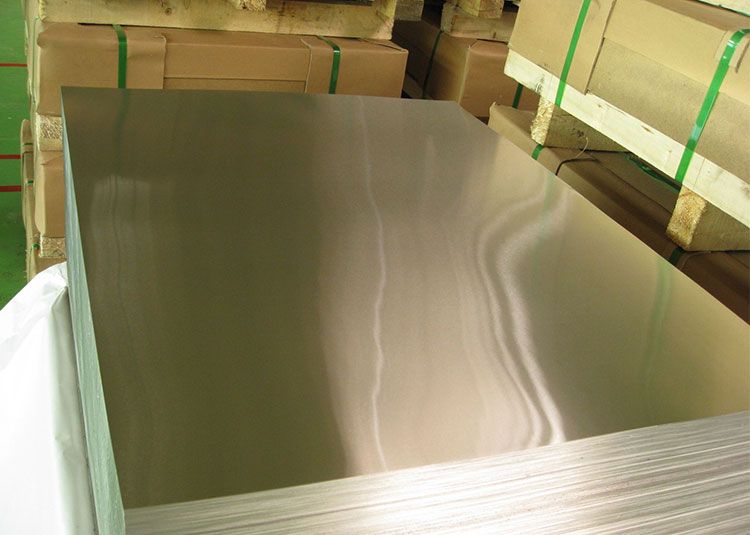

7. Surface Treatment & Finishing Options

Surface treatments enhance corrosion resistance, durability, and aesthetics:

| Treatment | Typical Thickness / Spec | Benefits |

|---|---|---|

| Anodizing | 5–25 µm (decorative); up to ~60 µm (hard) | Improved corrosion resistance, color options, harder surface |

| Powder Coating | 60–120 µm | Durable color finish, good outdoor stability |

| PVDF Coating | 25–35 µm | Excellent UV and weather resistance for facades |

| Brushed Finish | – | Decorative appearance, hides minor scratches |

| Pattern/Embossed | – | Increased slip resistance, visual design |

Most 1mm and 2mm sheets for architectural use are supplied anodized or coated, while 5mm structural plates are often delivered mill finish for further machining or welding.

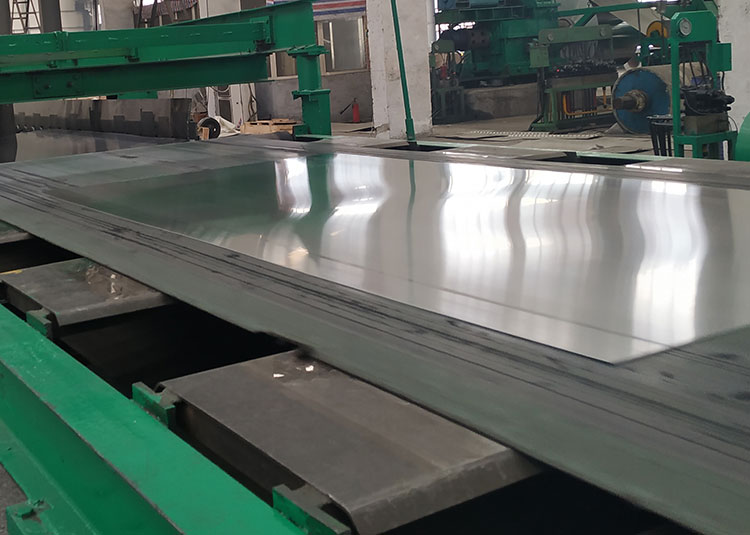

8. Fabrication & Processing

Aluminum sheets in 1mm, 2mm, and 5mm thickness can be processed using standard equipment:

| Process | 1mm | 2mm | 5mm |

|---|---|---|---|

| Cutting | Shear, laser, punching | Shear, laser, plasma, punching | Sawing, plasma, waterjet, milling |

| Bending | Easy bending, small radii | Moderate radii; press brake | Requires higher tonnage, larger radii |

| Welding | TIG, MIG (all thicknesses) | TIG, MIG | MIG, TIG; pre‑heat may help in thick sections |

| Forming/Stamping | Excellent for ductile alloys | Good | Limited; mainly for simple bends |

| Machining | Not typical for structural | Limited machining | Common for structural and tooling |

Correct alloy–temper selection is critical to avoid cracking during bending, especially for 5mm sheets.

9. Benefits to Customers

- Weight Savings:

- ~66% lighter than steel for similar volume, reducing transport and installation costs.

- Corrosion Resistance:

- Natural oxide layer and optional anodizing/coating support long outdoor service life.

- Design Flexibility:

- Multiple thicknesses allow layered design: 1mm for covers, 2mm for panels, 5mm for structure.

- Ease of Fabrication:

- Compatible with common cutting, bending, and welding processes; short processing times.

- Recyclability:

- Aluminum is 100% recyclable with minimal property loss, supporting sustainable design.

- Attractive Appearance:

- Clean metallic finish; can be easily colored or textured for high-end architectural and consumer products.

10. Selecting the Right Thickness

Use the following simplified guide when choosing between 1mm, 2mm, and 5mm:

| Design Requirement | Recommended Thickness |

|---|---|

| Lightweight cover, non‑load‑bearing | 1mm |

| Indoor panels, signage, trims | 1–2mm |

| Building facade, semi‑structural panels | 2mm |

| Machine guards, equipment panels | 2mm |

| Structural frame, base plate, tool plate | 5mm |

| Marine or heavy-duty flooring | 5mm (often patterned) |

For projects with specific mechanical, environmental, or regulatory requirements, final selection should consider alloy, temper, design load, and safety factors in accordance with applicable engineering standards.

By the performance differences and proper use cases of 1mm, 2mm, and 5mm aluminum sheets, customers can optimize their designs for strength, cost efficiency, and long-term durability.