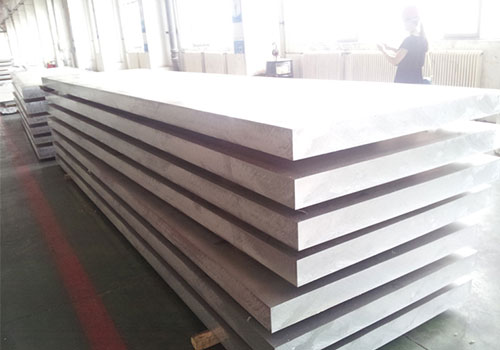

In the landscape of modern engineering and production, the use of aluminum alloys promises unparalleled performance, specifically the 7050 T7451 aluminum plate. This particular alloy stands out due to its superior mechanical properties and corrosion resistance, making it the pivotal embedding material across sectors like aerospace, automotive, and marine industries.

7050 T7451 Aluminum Plate: The Basics

The 7050 aluminum alloy belongs to the family of A7xxx series aluminum alloys, predominantly recognized for their high strength due to their zinc content. The T7451 temper, in particular, signifies a treatment standard that includes overaging to enhance its stability across various temperature readings. What sets the 7050 alloy apart can be summarized via its striking chemical composition and physical performance parameters that strongly underline its structural integrity and durability.

7050-T7451 aluminum plate, with its high strength-to-weight ratio, is a workhorse in our factory, particularly favored for applications demanding exceptional fatigue resistance and toughness. However, its very properties present unique challenges. We've found that achieving consistent weld quality is paramount, as improper welding techniques can lead to cracking and significant reductions in the material's inherent strength. Pre-heating and specific filler metal selection are crucial, and we've invested heavily in training to ensure our welders are proficient in these techniques. Furthermore, the inherent work-hardening characteristics mean machining can be demanding, requiring specialized tooling and careful consideration of cutting speeds and feeds to prevent tool wear and surface defects. Careful planning and precise execution are to avoiding costly rework or scrap.

Beyond the fabrication challenges, another critical area is the material's aging characteristics. 7050-T7451's peak strength is achieved through a specific heat treatment, and any deviation from this process can result in compromised mechanical properties. We maintain rigorous quality control checks at every stage of production, from incoming material inspection to final product testing. This includes regular calibration of our heat treatment equipment and meticulous documentation of every batch. Moreover, the plate's susceptibility to stress corrosion cracking requires careful consideration of the operating environment for the final product. We often advise our clients on surface treatments and protective coatings to mitigate this risk, ensuring the longevity

Chemical Properties Table

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | Balance |

| Zinc (Zn) | 6.0 - 7.7 |

| Magnesium (Mg) | 2.2 - 2.9 |

| Copper (Cu) | 2.0 - 3.0 |

| Chromium (Cr) | ≤ 0.10 |

| Zirconium (Zr) | 0.10 - 0.20 |

| Iron (Fe) | ≤ 0.15 |

Parameters: Mechanics and Tempering

The following markers characterize the accomplishments of 7050 T7451 aluminum plate:

- Yield Strength: approximately 500 MPa.

- Ultimate Tensile Strength: can reach up to 570 MPa under specific conditions.

- Elongation at Break: about 8%, showing this alloy's capacity for significant deformability.

- Hardness: measures around 155 HB (Brinell Hardness).

- Modulus of Elasticity: approximately 70 GPa, providing great elasticity for dynamic applications.

The T7451 temper post-anodization treatment normally follows a detailed procedure compromising the material's crucial mechanical properties while adding optimum resistance along with enhancing airframe performance characteristics.

Implementation Standards for 7050 T7451 Aluminum

The application of the 7050 T7451 must incorporate peer-reviewed standards set forth in ASTM B490 as well as following guidelines laid down by AMS standards constituting aluminum sheet/plate assemblies. Here are pinpointed mentions of specifications necessary for employing this versatile material:

- AMS 4047: Pertains to the airflow properties protection mechanisms.

- ASTM B211: Determines the replicability in most of the toughness and pliable configurations permitted for airline modules.

Alloy Tempering and Integrated Processes

Alloy tempering methods applied to 7050 T7451 reveal intrinsic insights about stripping teeter-treavings caused by high-stakes applications often renowned in military aircraft repairs and heavier loads. Controlled over-aging follows cad-python solutions heating where promptly plate materials can remove post-plating intricacies to unleash facets about proximal effectiveness against topical matters inclusive of oils, moisture and electromagnetic rafting:

- Flame Treatment: This regime allows partial revitalization of yield performance regarding existing work efforts.

- Weld Ignapia Intensity Promotion: Strength optimalizes the tympanic cohabitation enabled by the wavelengths interacting on interstitial poised zones.

Applications: Where Strength Meets Meaning

Given the assessed mechanical prowess of the 7050 T7451, it’s no surprise that it occupies critical lifecycle spots in diverse avenues. Here's a clear focus on prestigious sub-elmunic exploitive implementations such as:

- Aerospace Components: Look at fuselage and wing plates equipped with woven-an_fround foundations for aerial stalwartness revisions under circumspect day-weather exigencies.

- Automotive Structures for Racing: Light weighted yet monumental engineering fluids directed urgency-based tank coverings.

- Marine Equipment: Protection against surface erosion that high-performance watercraft sectors demand.