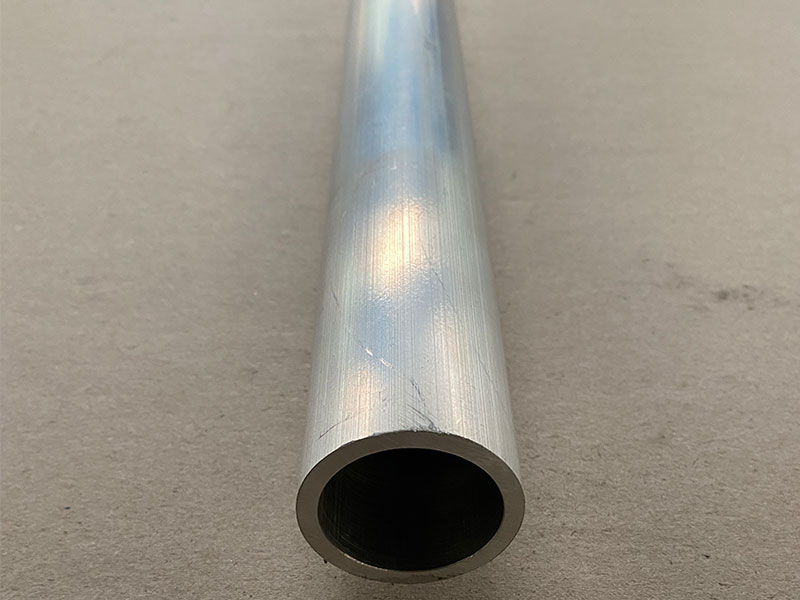

6082 is one of the most widely used aluminum-magnesium-silicon (Al-Mg-Si) alloy grades for structural applications in marine and offshore environments. When produced as tubes, 6082 offers an excellent combination of strength, weldability, corrosion resistance, and machinability that makes it ideal for a broad range of offshore equipment and structural components.

Features

- High strength-to-weight ratio: 6082 delivers elevated tensile and yield strengths among the 6xxx series, making it suitable for load-bearing offshore components.

- Good corrosion resistance: The Al-Mg-Si chemistry provides robust resistance to seawater and atmospheric corrosion, especially after anodizing or with proper surface treatments.

- Excellent weldability: Compatible with common welding methods (TIG, MIG/ GMAW, arc-welding variants); minimal preheating required and predictable weld properties with correct filler alloys.

- Good machinability: Responds well to conventional machining, enabling precise tubing dimensions and tight tolerance fabrication.

- Heat-treatable: Age-hardening (T6, T651) allows selection of final temper to balance strength, stress relief, and dimensional stability.

- Formability: Suitable for extrusion and some bending operations (subject to temper and tube geometry).

- Surface finish: Can be supplied mill finish, anodized, or coated for additional corrosion protection and aesthetics.

Typical Applications in Offshore and Marine Equipment

- Structural tubing for decks, platforms, ladders, handrails, and stanchions

- Hydraulic and pneumatic riser protective sleeves

- Frames and support structures on jack-ups, semi-submersibles, and floating platforms

- Marine piping supports, cable trays, and conduit housings

- Buoyancy and floatation component frames where lightweight corrosion resistance is key

- Winch housings, masts, and substructure members for helidecks and service cranes

- Corrosion-resistant housings and enclosures for electronic instrumentation and sensors

Chemical Composition (EN AW-6082 / AlSi1MgMn Equivalent)

Typical composition ranges (wt%) — meets EN 573 / EN 754 / ISO 6361 requirements:

- Aluminum (Al): Balance

- Silicon (Si): 0.7 – 1.3

- Iron (Fe): ≤ 0.5

- Copper (Cu): ≤ 0.10

- Manganese (Mn): 0.4 – 1.0

- Magnesium (Mg): 0.6 – 1.2

- Chromium (Cr): ≤ 0.25

- Zinc (Zn): ≤ 0.25

- Titanium (Ti): ≤ 0.10

- Others (each): ≤ 0.05; (total others) ≤ 0.15

Note: Exact chemical limits depend on specification and producer; certified material test reports (MTRs) should be provided with shipments.

Mechanical Properties by Temper

Mechanical properties vary with temper. Representative values for extruded/seamless tubes:

O (Annealed)

Tensile strength (Rm): 120 – 190 MPa

Yield strength (Rp0.2): ≤ 70 MPa

Elongation (A50): ~10 – 20%

T4 (Solution heat-treated and naturally aged)

Rm: 220 – 275 MPa

Rp0.2: 110 – 160 MPa

Elongation: 8 – 12%

T6 / T651 (Solution heat-treated and artificially aged; T651 includes stress relieving by stretching)

Rm: 260 – 340 MPa (typical 275–310 MPa)

Rp0.2: 140 – 300 MPa (typical 200–260 MPa)

Elongation: 5 – 12% depending on section size and exact temper

Designers should use certified mechanical data from the tube supplier for structural calculations and for finite element analyses.

Dimensional Tolerances and Sizes

6082 marine aluminum tubes can be manufactured as welded, extruded, or seamless tubes. Typical offerings include:

- Outer diameter (OD): 10 mm up to 508 mm (and larger by special order)

- Wall thickness: 0.7 mm to 50 mm (depending on OD and production method)

- Lengths: random cut, fixed increments (e.g., 6 m), or custom cut-to-length

- Tolerances: conform to EN 755-2, EN 485-4, or customer-specific tolerances. Typical OD tolerance for extruded tubes: ±0.3 mm for small sections, ±0.5 mm for larger sections; roundness and straightness tolerances depend on production.

For critical offshore fittings, specify tolerances explicitly in purchase order.

Surface Treatments and Corrosion Protection

- Mill finish: As-extruded or as-welded surface; suitable where aesthetics are not critical.

- Anodizing: Improves corrosion resistance and finish; typical types include Type II (sulfuric) and Type II/III with sealing.

- Conversion coatings: Chromate-free treatments (e.g., Alodine, non-chromate alternatives) for improved paint adhesion.

- Powder coating or liquid paints: For additional barrier protection and color/brand identification.

- Cathodic protection and sacrificial anodes: When used in aggressive seawater environments, complement tube material selection with system-level corrosion control.

- Surface passivation: For welds and heat-affected zones, consider post-weld cleaning and passivation.

Welding, Joining and Fabrication

- Common welding processes: GTAW (TIG), GMAW (MIG), and pulsed variants; filler alloys such as ER5356 or ER4043 are commonly used depending on required mechanical properties and corrosion resistance.

- Pre-weld cleaning: Remove oil, grease, oxides, and contaminant for best weld quality.

- Minimizing heat input: Use proper parameters to avoid excessive softening in HAZ (heat affected zone).

- Post-weld treatment: Stress relieving (e.g., stretching for T651), mechanical straightening, and local anodizing or protective coatings to restore corrosion resistance.

- Joining to dissimilar metals: Beware galvanic corrosion. Use insulating joints, isolation layers, or compatible fasteners (stainless steel with insulation, aluminum fasteners) to prevent bimetallic corrosion.

- Bending and forming: Limited by temper; O and T4 tempers are more formable. Cold-bending large-diameter or thick-walled tubes may require annealing.

Standards and Certifications

Commonly applicable standards and specifications for 6082 aluminum tubes:

- EN 755 (Aluminium and aluminium alloy extruded rod/bar, tube and profiles)

- EN 573 (Chemical composition of aluminium alloys)

- EN 485 (Aluminium and aluminium alloys — sheet, strip and plate — mechanical properties)

- ISO 6361 (Wrought aluminium and aluminium alloys)

- ASTM B221 (Extruded aluminum structural tubing) — if specifying to ASTM practice

- National/regional marine/offshore standards: DNVGL, ABS, Lloyd’s Register requirements for materials and fabrication for offshore structures

- MIL-SPEC or project-specific material acceptance tests (MTCs/MTRs) are often required for critical offshore equipment

Quality Control and Testing

For offshore use, expect the following tests/controls:

- Chemical analysis (OES/ICP) and Material Test Reports (MTR)

- Mechanical testing: tensile tests (longitudinal and transverse where required), hardness

- Non-destructive testing (NDT): eddy current for wall integrity, UT for thick sections, dye-penetrant inspection for welds

- Dimensional inspection and dimensional certificates

- Surface quality inspection: visual and optical checks for pitting, inclusions, and extrusion defects

- Corrosion testing: salt spray / cyclic corrosion / immersion tests for qualifying coatings or specific project needs

Design Considerations for Offshore Use

- Factor in corrosion allowance and protective coatings for long life in marine atmospheres and splash zones.

- Account for fatigue performance: welded joints and cyclic loading conditions require fatigue-rated designs. Use fatigue data for 6xxx series alloys as appropriate and apply safety factors.

- Thermal considerations: 6xxx alloys have good thermal conductivity but will change mechanical properties with temperature; consider any service temperature extremes.

- Avoid dissimilar metal contact without isolation to reduce galvanic corrosion risks.

- Use appropriate fasteners and design details to prevent crevice corrosion and water entrapment.

- Material traceability: ensure full MTRs, heat numbers, and traceability for all structural components.

Advantages over Other Alloys

- Compared with 6061: 6082 typically offers higher strength in the T6 condition and similar corrosion resistance but comparable weldability. Choice depends on availability and specific mechanical target.

- Compared with stainless steel: lighter weight and easier fabrication, though stainless steels may provide superior toughness in certain conditions — cost and weight trade-offs often favor aluminum for offshore non-critical load-bearing applications.

- Compared with 5xxx series (Al-Mg): 5xxx alloys may have better corrosion resistance in marine environments but 6082 (6xxx) provides superior strength when heat-treated.

Typical Supply and Packaging

- Bundled tubes on wooden pallets with protective end caps

- Plastic wrapping, anti-corrosive wrapping for long sea voyages

- Marking: alloy grade (6082), temper (e.g., T6/T651), heat/batch number, dimensions, manufacturer

- Documentation: MTR, packing list, certificate of conformity, NDT reports if applicable

Procurement Checklist

When ordering 6082 marine aluminum tubes for offshore equipment, include the following in your purchase order:

- Alloy and temper (e.g., EN AW-6082 T6 / T651)

- Tube type (extruded/seamless/welded)

- Dimensions: OD, wall thickness, length tolerance, straightness, roundness requirements

- Mechanical property requirements and test certificates (MTRs)

- Surface finish and coating (anodized, conversion coated, painted)

- NDT requirements and acceptance criteria

- Traceability requirements and heat number reporting

- Packaging and delivery conditions for marine shipment

- Project-specific certifications (DNV, ABS, Lloyd’s) if required