6082 T6 quench-treated aluminum plate is a high-strength, heat-treatable wrought alloy in the 6xxx series (Al-Mg-Si). It combines excellent mechanical properties, good corrosion resistance, and high machinability with favorable weldability and formability. After solution heat treatment, quenching and artificial ageing to the T6 temper, 6082 reaches an optimal balance of strength and ductility, making it a versatile choice for structural and load-bearing applications.

Features

- High strength for a 6xxx-series alloy (notably higher than 6061 in many conditions).

- Good corrosion resistance, especially in marine and industrial atmospheres.

- Excellent weldability with common processes (GTAW/TIG, GMAW/MIG).

- Good machinability and surface finish after T6 treatment.

- Good formability in the soft (O) condition; moderate formability after T6.

- Stable mechanical properties across thicknesses commonly produced as plates.

- Suitable for anodizing for enhanced surface protection and appearance.

Typical Chemical Composition (wt%)

| Element | Range (%) |

|---|---|

| Al | Balance |

| Si | 0.7–1.3 |

| Fe | 0.50 max |

| Cu | 0.10 max |

| Mn | 0.40–1.0 |

| Mg | 0.6–1.2 |

| Cr | 0.25 max |

| Zn | 0.25 max |

| Ti | 0.1 max |

| Others | 0.15 max |

Notes:

- Values shown are typical ranges per common international standards (e.g., EN 573, ASTM designations may vary). Actual composition should be confirmed with supplier certification.

Mechanical Properties (Typical, T6 Temper)

| Property | Typical Value |

|---|---|

| Tensile strength (UTS) | 310–350 MPa |

| Yield strength (0.2% offset) | 260–300 MPa |

| Elongation (in 50 mm) | 8–12% |

| Brinell hardness (HB) | 95–125 |

| Modulus of elasticity | ~70 GPa |

| Density | 2.70 g/cm³ |

Notes:

- Mechanical properties depend on plate thickness and exact temper control. Thicker sections may have slightly reduced strength.

Physical & Thermal Properties

| Property | Value |

|---|---|

| Melting range | 555–650 °C |

| Thermal conductivity | ~160–180 W/m·K (varies with alloying) |

| Electrical conductivity | ~30–40% IACS |

| Coefficient of thermal expansion | ~23 x10^-6 /K |

| Specific heat capacity | ~0.9 J/g·K |

Processing & Heat Treatment

- Solution heat treatment: typically performed around 530–540 °C to dissolve Mg-Si precipitates.

- Quenching: rapid cooling (water quench) to retain a supersaturated solid solution.

- Artificial ageing (T6): ageing at ~160–180 °C for a controlled time to precipitate strengthening phases and reach the T6 temper.

- Machining: T6 plates machine well; tooling and speeds should be selected to control heat and chip formation.

- Welding: 6082 is weldable but can lose local strength in the heat-affected zone (HAZ). Post-weld heat treatment is rarely practical for large assemblies; design should account for reduced local properties or use appropriate filler alloys (e.g., 4043, 5356) and joint designs.

- Surface finishing: suitable for anodizing and conventional surface treatments (chemical conversion coatings, painting).

Performance Characteristics

- Strength-to-weight: High specific strength compared with many structural alloys, beneficial where weight reduction is critical.

- Corrosion resistance: Good general corrosion resistance; suitable for outdoor and marine environments when properly protected.

- Fatigue behavior: Good fatigue strength when produced with low internal defects and with appropriate surface finish.

- Dimensional stability: Stable after quench and ageing; minimal distortion if quenched with controlled conditions.

- Formability: Best formability in annealed condition. Some cold forming possible in T6 with risk of crack initiation; consider forming in O temper then heat-treating where complex shapes are required.

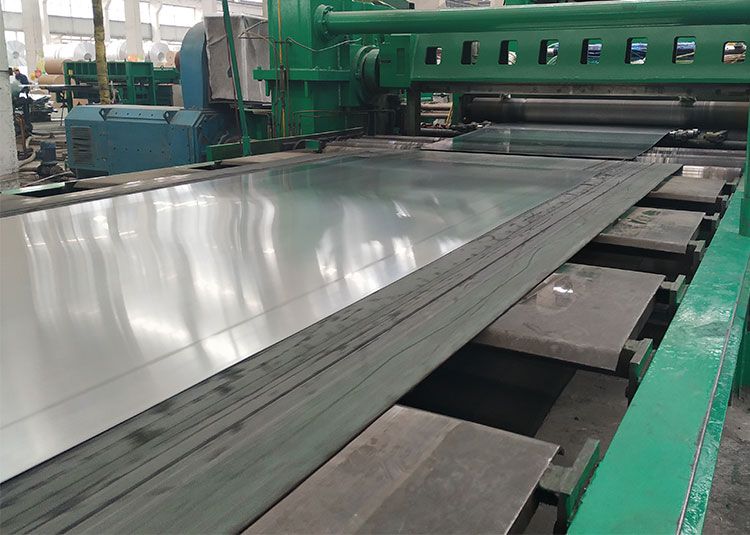

Typical Plate Specifications

| Parameter | Typical Range / Standard |

|---|---|

| Thickness | 3 mm – 200 mm (typical commercial) |

| Width | up to 2150 mm (mill dependent) |

| Length | cut to order; typical 2000–6000 mm |

| Surface Finish | Mill finish, shot-blasted, anodized |

| Standards | EN 573 / EN 485 / BS EN 755 / ASTM B209 (comparable) |

| Tempers | T6 (quench & artificial age), T651 (stress relieved & artificially aged) |

Applications & Use Cases

6082 T6 plate is widely used across industries that require a combination of strength, corrosion resistance, and machinability:

- Structural components: frames, chassis, girders, and load-bearing structures in rail, automotive, and general engineering.

- Transport: truck bodies, trailers, shipping containers, and components for buses and rail vehicles.

- Marine: superstructures, boat fittings, and components exposed to saltwater atmospheres (with appropriate design and protection).

- Machinery: machine bases, tooling plates, and components requiring high strength and good finish.

- Construction: architectural panels, balustrades, and supporting structures where strength and appearance matter.

- Hydraulic and pneumatic components: where machinability and strength-to-weight ratio are important.

- Renewable energy: frames and supports for wind and solar where strength and corrosion resistance are required.

Advantages

- Superior strength compared with many 6xxx alloys and some 5xxx alloys in similar conditions.

- Lightweight alternative to steel for structural applications, enabling fuel savings and easier handling.

- Good surface finish and ability to anodize for aesthetic and protective purposes.

- Reliable supply and well-understood processing routes for heat treatment and fabrication.

- Versatile across welding, machining, and finishing processes when best practices are followed.

Limitations & Considerations

- Reduced local strength in the weld HAZ; designs must accommodate or mitigate this with welding procedures, filler selection, or post-fabrication treatments.

- Not as formable in T6 as in the annealed condition; complex forming is typically done prior to final heat treatment.

- Thicker sections may show some reduction in mechanical properties due to quench cooling rates; check supplier data for thickness-dependent properties.

- For highly corrosive marine or chemical environments, additional surface protection or higher-corrosion-resistance alloys may be preferable.

Quality & Inspection

Recommended quality checks when procuring 6082 T6 plate:

- Chemical composition analysis (certified mill test report).

- Mechanical testing (tensile, yield, elongation) on representative samples.

- Hardness testing (Brinell or Rockwell).

- Non-destructive testing (ultrasonic, eddy current) for critical structural applications or thick plates.

- Visual and dimensional inspection per order specifications.

- Surface condition and straightness checks.

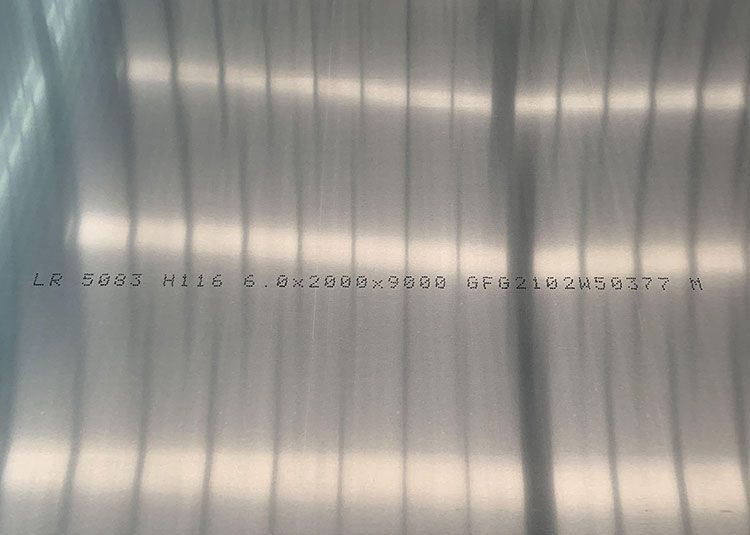

Ordering Guidance

When specifying 6082 T6 plate, include:

- Alloy and temper: 6082 T6 (or T651 if stress-relieved).

- Required thickness, width, and length tolerances.

- Surface finish (mill finish, anodized, shot-blasted).

- Mechanical property requirements (minimum UTS, yield, elongation).

- Certification requirements (material test reports, traceability).

- Any special processing: cutting, shot-blasting, edge finishing, pre-machining.

- Welding or fabrication needs that might affect temper choice or post-processing.