1060 Aluminium Sheet and Coil: A Quiet Workhorse Behind Everyday Performance

In the world of aluminum, some alloys are famous for strength or aerospace applications. 1060 aluminium is not one of them. Instead, it plays a quieter but vital role: delivering ultra-pure, highly formable, and reliable material for industries that value conductivity, corrosion resistance, and cost-efficiency above all else.

If your project calls for clean metal behavior rather than brute strength, 1060 aluminium sheet and coil is often the most rational, economical choice.

What Makes 1060 Aluminium Different?

1060 aluminium is a commercially pure aluminium alloy with an aluminium content of around 99.6%. That level of purity gives it several distinct characteristics:

- Very high electrical and thermal conductivity

- Excellent corrosion resistance, especially in normal atmospheric and many industrial environments

- Outstanding formability and deep-drawing performance

- Very low density, contributing to lightweight structures

- Non-magnetic and non-toxic, suitable for sensitive and food-related applications

Unlike high-strength 5xxx or 6xxx series alloys, 1060 is not designed for load-bearing structural applications. Instead, it excels where shaping, conductivity, and surface quality matter more than mechanical strength.

Typical Applications: Where 1060 Shines

Because of its high purity, 1060 aluminium sheet and coil appears in a surprisingly wide range of products:

- Electrical busbars and conductive strips

- Transformer windings and power distribution components

- Heat exchangers, evaporator panels, and thermal shields

- Lampshades, reflective panels, signboards, and decorative trim

- Kitchen utensils, cookware backs, and food equipment covers

- Chemical equipment with low mechanical stress but high corrosion-resistance needs

- Insulation jacketing and cladding for pipelines and equipment

Its ease of forming and welding makes 1060 especially attractive to fabricators who need to bend, draw, punch, or spin material quickly without cracking.

Parameters of 1060 Aluminium Sheet and Coil

While exact ranges depend on the producer and intended application, customers will generally encounter the following parameter ranges:

- Thickness: from ultra-thin foil-like gauges around 0.2 mm up to heavy sheet near 6.0 mm

- Width: standard widths from 1000 mm to 1500 mm are common; customized widths up to about 2000 mm may be available

- Coil inner diameter (ID): typically 505 mm or 610 mm for industrial processing lines

- Coil weight: can range from light coils around 500 kg for manual handling to 3–5 tons for continuous production lines

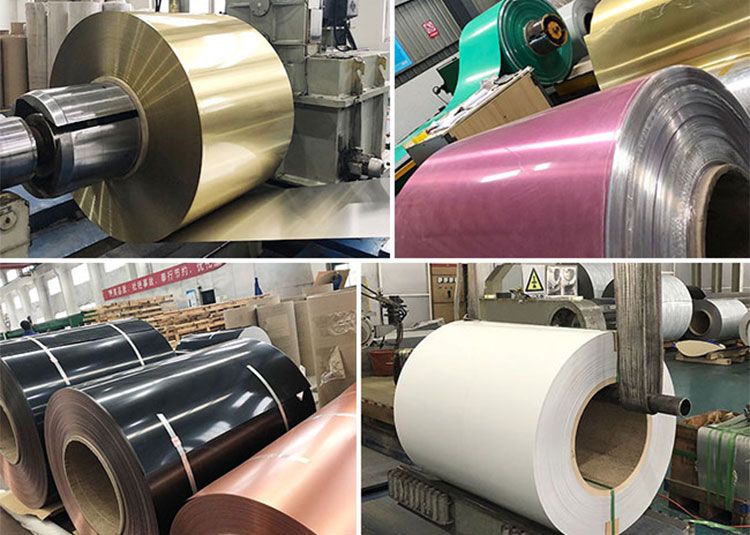

Surface finishes can include mill finish, brushed, embossed, or even color-coated, depending on downstream requirements. For electrical and thermal applications, a clean, oxide-stable surface is usually preferred.

Flatness, thickness tolerance, and edge quality are critical to automated processing, so coils are often supplied with tight dimensional tolerances and slit edges when needed.

Alloy Temper: How 1060 Is Supplied and Why It Matters

Because 1060 aluminium gains strength mainly through cold working (and not through heat treatment), temper selection is essentially a decision about the balance between strength and formability.

Common tempers for 1060 sheet and coil include:

O (Annealed):

The softest condition. Maximum ductility and deep-drawing capability. Ideal for complex shapes, spinning, stretching, and severe forming.H12 / H14:

Slightly strain-hardened conditions. Offer modest strength improvement while retaining good formability. Often used in general-purpose sheet, signboards, and light covers.H16 / H18:

Heavily strain-hardened. Higher strength and hardness, less formability. Useful where rigidity and surface stability are more important than deep forming.H24 / H26:

Strain-hardened and partially annealed tempers. These provide a controlled compromise between strength and ductility, commonly specified for products that must be formed but not severely drawn.

The choice of temper should be aligned with the downstream process:

- Complex, multi-step forming or deep drawing usually calls for O or very soft tempers.

- Simple bending, punching, and moderate forming can work well with H14 or H24.

- Flat panels, cladding, or components where stiffness is more critical than forming often favor H18 or H26.

Chemical Composition of 1060 Aluminium

The defining feature of 1060 alloy is its high aluminium content. Typical chemical composition (mass percent) is:

| Element | Content (%) |

|---|---|

| Al | ≥ 99.6 |

| Si | ≤ 0.25 |

| Fe | ≤ 0.35 |

| Cu | ≤ 0.05 |

| Mn | ≤ 0.03 |

| Mg | ≤ 0.03 |

| Zn | ≤ 0.05 |

| Ti | ≤ 0.03 |

| Others (each) | ≤ 0.03 |

| Others (total) | ≤ 0.10 |

This near-pure chemistry is what drives its high conductivity and predictable corrosion behavior. The low levels of alloying elements also mean excellent recyclability with minimal contamination issues.

Mechanical and Physical Properties at a Glance

Exact numbers vary with temper and thickness, but general property ranges include:

- Tensile strength (O temper): about 60–95 MPa

- Tensile strength (H18): roughly 110–145 MPa

- Elongation: up to 30% or more in soft temper, decreasing with higher strain hardening

- Density: about 2.70 g/cm³

- Electrical conductivity: approximately 55–60% IACS (International Annealed Copper Standard)

- Melting range: around 645–660°C

Those properties illustrate why 1060 is best viewed as a “functional” alloy rather than a structural one. Its real value lies in conductivity, low weight, and clean forming behavior.

Production Standards and Quality Framework

Reputable producers manufacture 1060 aluminium sheet and coil in line with international standards such as:

- ASTM B209 for aluminium and aluminium-alloy sheet and plate

- EN 485 / EN 573 for wrought aluminium products and chemical composition

- GB/T 3880 series for rolled aluminium in some regional markets

These standards regulate aspects like composition limits, mechanical properties, dimensional tolerances, and inspection rules.

On top of formal standards, many end users specify:

- Strict thickness tolerances for consistent stamping and bending

- Narrow flatness limits to ensure reliable feeding into presses and roll formers

- Surface quality levels (free from oil stains, heavy scratches, or rolling defects)

- Coil winding quality, with controlled tension and minimal telescoping

For electrical and thermal applications, surface oxide uniformity and absence of contaminants become especially critical.

Processing Behavior: A Material That Cooperates

One of the hidden strengths of 1060 aluminium is how “cooperative” it is in the workshop and on production lines.

- Forming: In soft tempers, 1060 can be bent to tight radii, deeply drawn, or spun into smooth, complex shapes without cracking.

- Welding: It is readily weldable using common methods like TIG and MIG. Filler selection is straightforward due to its purity.

- Cutting: Works well with shearing, sawing, laser cutting, and punching; burr levels are usually low with proper tooling.

- Surface treatment: Can be anodized for improved corrosion resistance and appearance, or painted and coated for decorative and protective purposes.

This combination of processing advantages reduces tool wear, shortens setup times, and minimizes scrap, ultimately lowering fabrication costs.

When 1060 Is the Right Choice

For engineers, buyers, and fabricators, the decision to use 1060 aluminium sheet and coil often comes down to a few simple priorities:

- Need for high electrical or thermal conductivity

- Need for high formability and excellent deep-drawing performance

- Moderate to low mechanical loads in service

- Desire for low weight and corrosion resistance

- Pressure to control material and processing cost

If those criteria match your project, 1060 is usually not just “good enough” – it is the optimal, purpose-fit solution.

Bringing It All Together

1060 aluminium sheet and coil is not designed to impress with extreme strength or exotic chemistry. Its value lies in reliable, repeatable performance in the background: carrying current, conducting heat, forming clean shapes, and resisting corrosion for years.

its parameters, temper options, and standardized properties allows you to specify 1060 with precision:

- Choose the temper that matches your forming needs.

- Match thickness, width, and coil configuration to your production line.

- Use the chemical and mechanical profiles to validate compliance with your industry standards.

With the right specification, 1060 aluminium becomes a predictable, efficient, and cost-effective foundation for products that simply have to work—quietly and reliably.