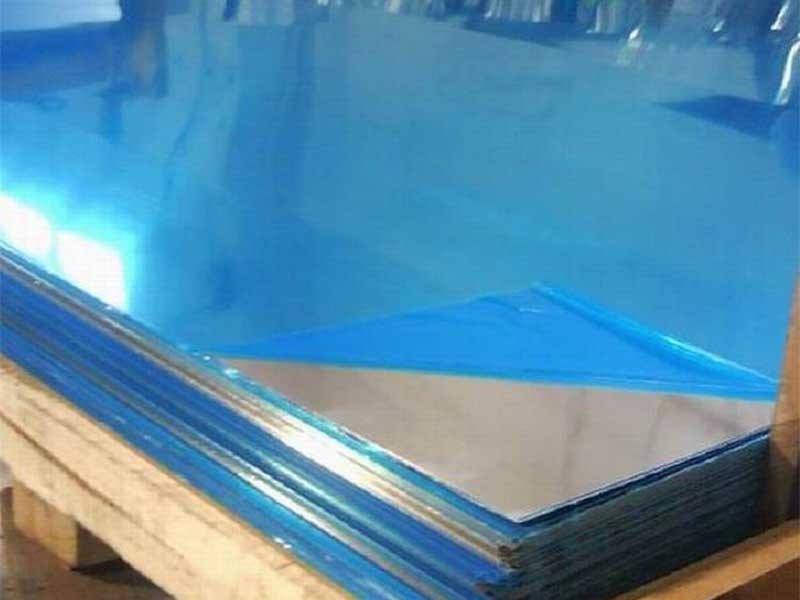

Mirror aluminum sheets such as 1050 and 1100 grades are highly coveted in various industries due to their exceptional reflective finish, corrosion resistance, and lightweight properties. These sheets provide outstanding aesthetics and practical performance, making them a preferred choice across commercial, architectural, and industrial applications.

What is Mirror Aluminum Sheet?

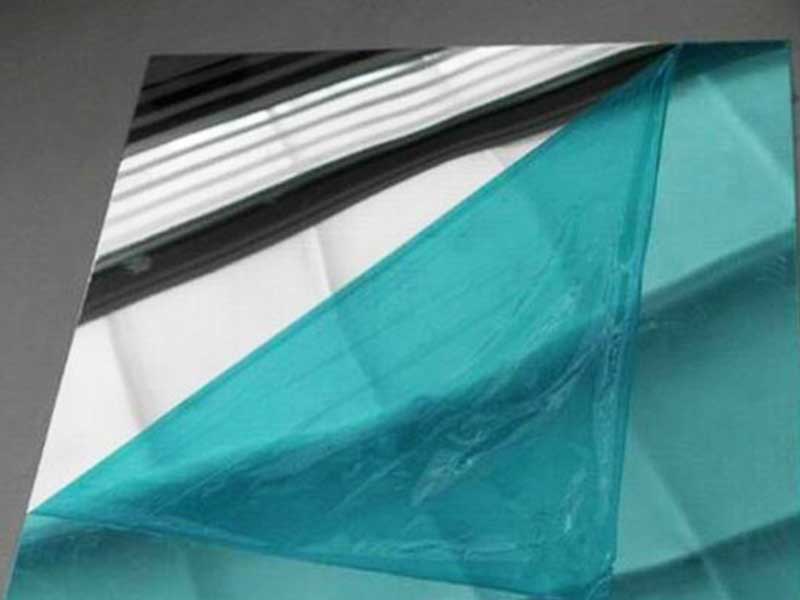

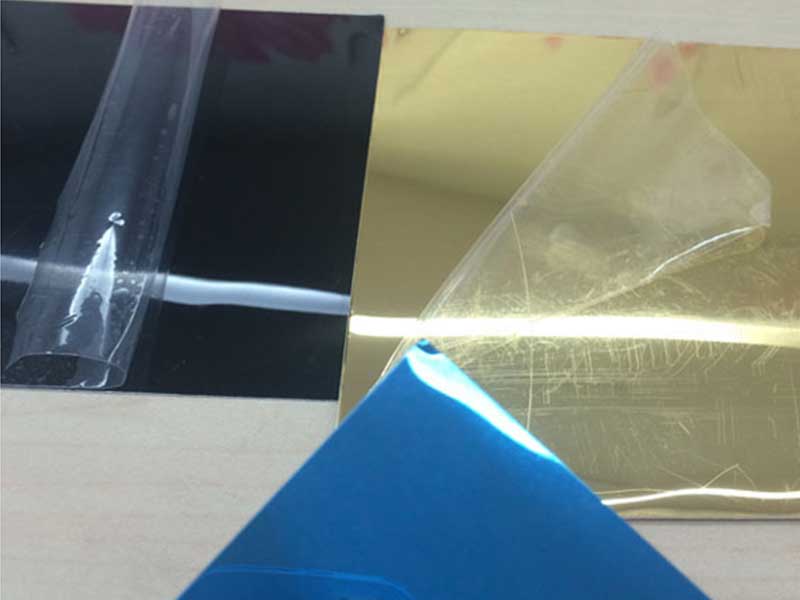

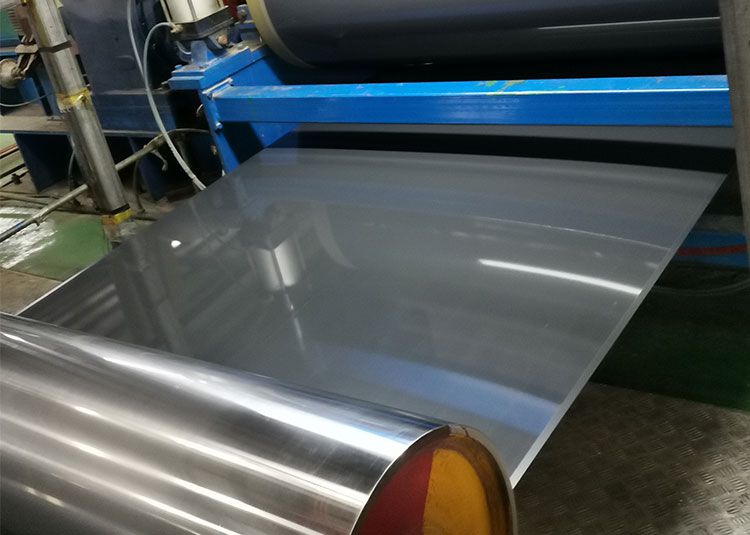

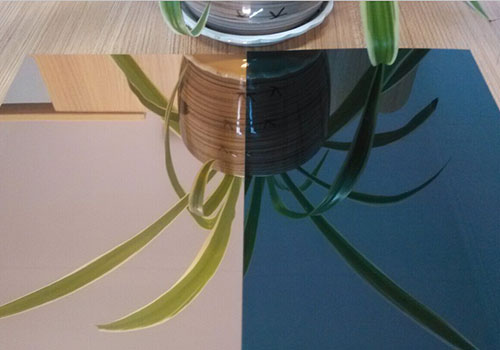

A mirror aluminum sheet is an aluminum product with a polished surface similar to a mirror. Highly reflective and smooth, these sheets offer an elegant appearance along with the structural benefits of aluminum. The 1050 and 1100 grades are categorized under commercially pure aluminum, containing high aluminum content which enhances their workability and corrosion resistance.

Functions and Features of 1050 and 1100 Mirror Aluminum Sheets

Highly Reflective Surface

The primary feature is the mirror-like finish obtained through precision polishing techniques. It provides a decorative, shiny surface that is resistant to tarnishing.Corrosion Resistance

Both 1050 and 1100 grades offer excellent resistance to atmospheric corrosion, scale, and oxidation, suitable for long-term use in varied environments.Excellent Workability

Due to their high aluminum content, these sheets are soft and ductile, allowing effortless cutting, bending, and rolling.Lightweight yet Durable

Aluminum’s low density ensures lightweight materials without compromising strength, which allows easy handling and installation.Non-toxic and Eco-Friendly

Being non-toxic makes these mirror sheets ideal even for food and pharmaceutical applications.

Applications of Mirror Aluminum Sheets 1050 and 1100

| Industry | Application Examples |

|---|---|

| Decorative | Interior decoration, wall panels, ceilings |

| Architectural | Facades, reflectors, signage, sunreflectors |

| Food & Beverage | Equipment, containers, cleanroom surfaces |

| Electronics | Reflective heat sinks, electronic casing |

| Automotive | Decorative trims, reflector parts |

| Furniture | Furniture claddings, mirrors and backdrops |

Their versatility extends to bespoke crafts, aviation interiors, reflectors in lighting industries, and even household items.

Technical Parameters and Standards

These mirror aluminum sheets conform to standard industry specifications while providing reliable dimensions and uniform surface finish.

| Parameter | 1050 | 1100 | Unit |

|---|---|---|---|

| Alloy Composition | Aluminum ≥ 99.5% | Aluminum ≥ 99.0% | % |

| Thickness Range | 0.2 - 3.0 | 0.2 - 3.0 | mm |

| Width Range | Up to 1500 | Up to 1500 | mm |

| Surface Finish | Mirror Polished | Mirror Polished | - |

| Density | 2.71 | 2.71 | g/cm³ |

| Temper Variety | O, H14, H24, H16 | O, H14, H24, H16 | - |

| Tensile Strength (Ultimate) | 65–110 | 65–110 | MPa |

| Yield Strength Matsumura (Offset 0.2%) | 35 | 35 | MPa |

Implementation Standards

| Standard | Description |

|---|---|

| ASTM B209 | Standard Specification for Aluminum and Aluminum-Alloy Sheet and Plate |

| EN 485-2 | Aluminum and aluminum alloys - Sheet, strip, and plate |

| GB/T 3880 | Aluminum and aluminum alloy chemical composition |

| JIS H4000 | Aluminum and aluminum alloy flat products |

Alloy Tempering Conditions

| Temper Designation | Description | Characteristics |

|---|---|---|

| O | Annealed (Soft state) | Maximum softness, excellent formability |

| H14 | Strain-hardened, partially hard | Improved strength, still good formability |

| H16 | Strain-hardened, moderately hard | Balanced strength and hardness |

| H24 | Strain-hardened and partially annealed | Excessive strength while workable |

For applications requiring deep drawing work or bending, annealed (O-temper) sheets are most appropriate due to their flexibility.

Chemical Composition of 1050 and 1100 Aluminum

| Element | 1050 (wt%) Max | 1100 (wt%) Max |

|---|---|---|

| Aluminum (Al) | ≥ 99.5 | ≥ 99.00 |

| Copper (Cu) | 0.05 | 0.05 |

| Iron (Fe) | 0.4 | 0.95 |

| Manganese (Mn) | 0.05 | 0.05 |

| Silicon (Si) | 0.25 | 0.95 |

| Zinc (Zn) | 0.10 | 0.10 |

| Titanium (Ti) | 0.03 | 0.03 |

| Others | 0.03 | 0.05 |

Advantages of Choosing 1050 and 1100 Mirror Aluminum Sheets

Due to their unparalleled finish and technical characteristics, these aluminum mirror sheets benefit customers who need:

- Outstanding corrosion resistance without additional coatings

- Lightweight and maintainable surfaces with minimal oxidation

- Flexibility for crafting and shaping to customized forms

- Non-magnetic and non-toxic materials fit for hygienic environments