Aluminum Plate Coil for Traffic Sign 1100 1050 1060 1070: A Practical Engineer’s View

When city planners talk about “intelligent traffic systems,” most people think about cameras and software. Yet, long before the electronics, the reliability of a traffic sign still depends on something very basic: the aluminum plate coil behind the reflective film. Alloys 1100, 1050, 1060 and 1070 form the quiet backbone of this system.

Looking at these alloys from an engineer’s angle helps clarify why they dominate traffic sign production and how small technical differences translate into performance on the road.

Why 1100, 1050, 1060, 1070 for traffic signs?

These four alloys belong to the 1xxx series of commercially pure aluminum. Their aluminum content is very high, and the sequence 1050–1060–1070–1100 represents slightly different purity and trace elements.

From a traffic sign manufacturer’s perspective, they share several critical traits:

- High reflectivity after proper surface treatment

- Excellent formability for bending, flanging, and embossing

- Lightweight yet stiff enough in plate form

- Strong corrosion resistance in outdoor environments

- Consistent surface quality for high-adhesion reflective films and inks

Where they diverge is in purity, mechanical behavior, and cost. This subtle divergence is where efficient traffic sign design happens.

Functional roles in the traffic sign system

Think of the aluminum plate coil as the structural and optical foundation of the sign:

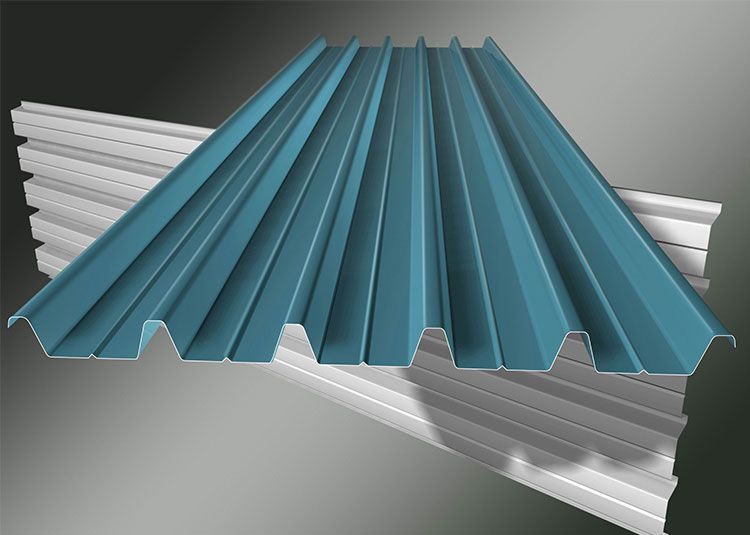

Structural backbone

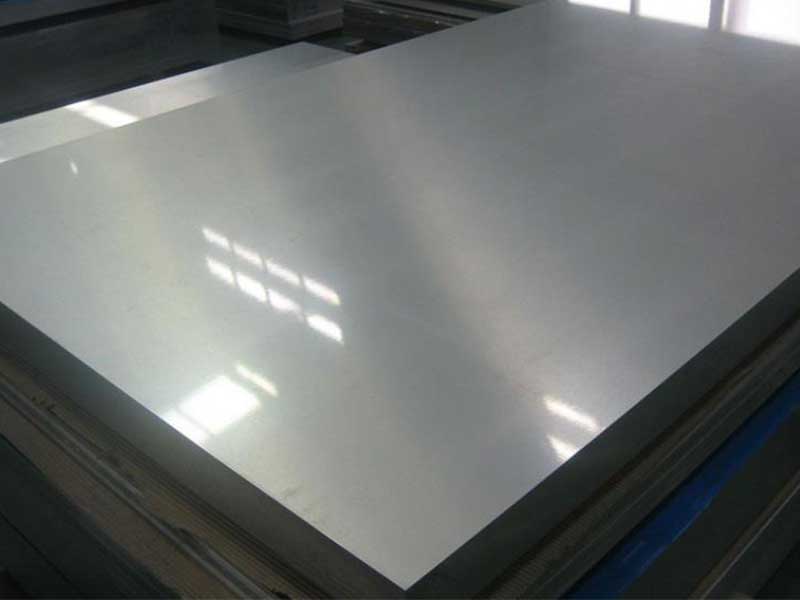

The plate provides flatness, dimensional stability and wind resistance. With thickness typically between 1.0–3.0 mm (often 1.0–2.5 mm for standard road signs), coils are unrolled, sheared, punched, and formed into final panels.Optical base

The surface roughness, brightness, and uniformity directly affect how reflective films appear at night. 1xxx series alloys have natural brightness and can be chemically or mechanically treated to optimize adhesion and avoid “orange peel” under films.Processing interface

The alloy and temper must tolerate shearing, drilling, rounding corners, and edge deburring without cracking. This is why soft to half-hard tempers such as H14, H24 or O are favored instead of very hard tempers.

In essence, the aluminum makes the sign durable, legible, and producible at scale.

Distinctive viewpoint: choosing by “behavior,” not just alloy number

Instead of thinking “1100 vs 1050 vs 1060 vs 1070” as static labels, it’s more useful to view each alloy as a behavioral profile under processing and outdoor exposure.

Alloy 1050 – the flexible workhorse

Aluminum content is around 99.5%. It bends easily, tolerates deep drawing, and is ideal where heavy forming or complex shapes are required. It is the typical choice for small to medium signs, embossed plates, and sign blanks requiring many punched holes.Alloy 1060 – purity-driven stability

Aluminum purity is about 99.6%. It offers slightly better electrical and thermal conductivity and extremely smooth surface quality after rolling. For high-end reflective signage where color uniformity and film bonding must be perfect, 1060 provides very consistent behavior.Alloy 1070 – near-maximum purity

Around 99.7% aluminum, 1070 is used when exceptional surface brightness and corrosion resistance are required. It is often selected for premium-grade reflective sheets, coastal or chemically aggressive environments, and for manufacturers who demand very low impurity levels to ensure predictable anodizing and coating.Alloy 1100 – strengthened by trace copper

Although also high in aluminum, 1100 contains small amounts of copper that raise strength compared to ultra-pure grades. It is a good compromise between formability and mechanical strength, especially where larger panels need to resist wind load and handling damage.

Instead of picking a single “best” alloy, advanced sign factories often match alloy and temper to sign size, bending radius, installation environment, and loading conditions.

Typical product parameters for traffic sign coils and plates

While each project can differ, traffic sign aluminum plate coil is usually supplied with:

Thickness range: about 0.3–3.0 mm

Thin gauges for reflective laminates and composite structures; mid gauges (1.2–2.5 mm) for stand‑alone sign panels.Width: typically 800–1600 mm

Matching the maximum sign width or optimizing nesting for cutting machines.Coil inner diameter: commonly 505 or 508 mm

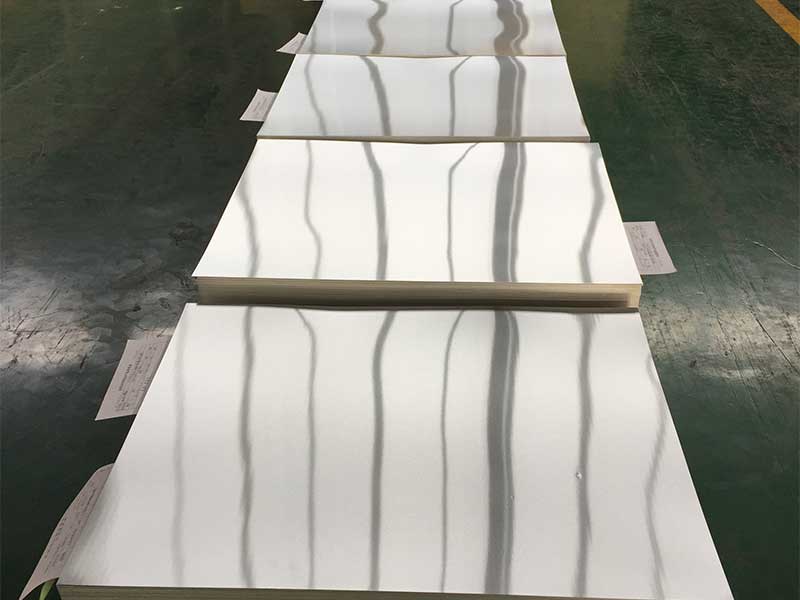

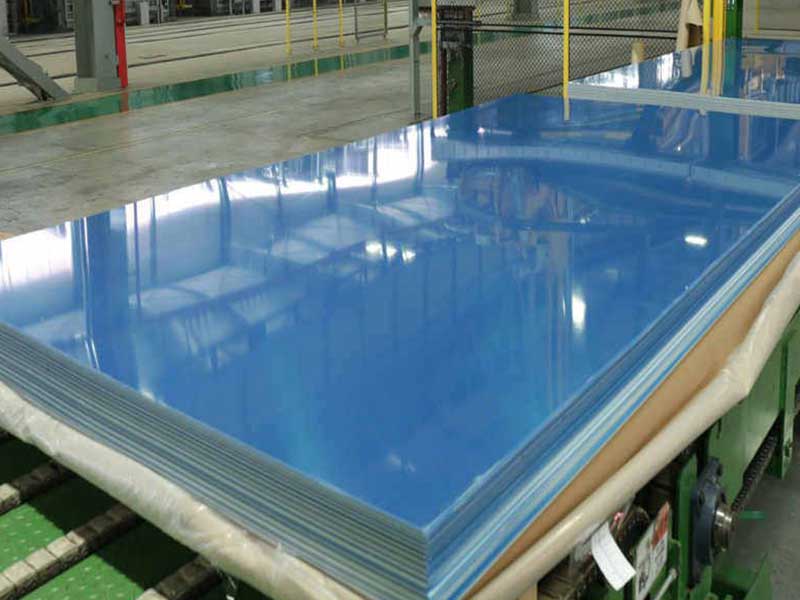

Compatible with most decoilers and slitting lines.Surface finish: mill finish, brushed, or lightly embossed

Optimized for reflective film lamination and screen / digital printing.Edge: slit or mill edge

According to cutting method and downstream safety requirements.

Mechanical properties depend on temper, but for sign use they are usually kept in a moderate range to balance strength and formability.

Temper choices: tuning the processing window

Temper designations such as O, H12, H14, H16, H24 describe how much cold work the aluminum has undergone and whether it has been partially annealed.

Typical tempers for traffic sign plates include:

O (annealed)

Very soft, extremely formable. Used for deep forming or where tight bending radii are needed. Less common for large flat signs due to lower stiffness.H12 / H14

Quarter‑hard to half‑hard. The most commonly used range, combining sufficient rigidity for flat panels with safe bending and punching behavior.H16 / H18

Harder tempers, with higher yield strength but lower elongation. Occasionally used where very thin sheets must remain flat and resist buckling, but require careful handling to avoid cracking at bends.H24

Cold worked and then partially annealed. Often selected when moderate forming and good flatness must coexist.

For traffic signs, the “sweet spot” is typically 1050, 1060 or 1100 in H14 or H24, giving clean edges after punching and allowing routine bending (for flanged edges and stiffeners) without failure.

Implementation standards and compliance

Traffic sign aluminum plate coils in 1100, 1050, 1060 and 1070 are usually produced in line with both alloy and application standards. Depending on the region, producers refer to:

- GB/T or EN standards for chemical composition and mechanical properties of wrought aluminum

- ASTM standards such as ASTM B209 for aluminum and aluminum-alloy sheet and plate

- National or local road sign standards that define minimum thickness, corrosion resistance, wind load performance, and retroreflective performance (the latter in combination with the reflective sheeting)

Compliance matters because agencies require predictable behavior over many years. The aluminum base must maintain flatness, resist pitting and corrosion, and support reflective films throughout the sign’s service life.

The chemical properties of these alloys are tightly controlled. The following table summarizes typical composition ranges (percent by weight, approximate values based on international standards):

| Alloy | Al (min) | Si + Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Others each (max) | Others total (max) |

|---|---|---|---|---|---|---|---|---|

| 1050 | 99.50 | 0.40 | 0.05 | 0.05 | 0.05 | 0.05 | 0.03 | 0.10 |

| 1060 | 99.60 | 0.35 | 0.05 | 0.03 | 0.03 | 0.05 | 0.03 | 0.10 |

| 1070 | 99.70 | 0.25 | 0.04 | 0.03 | 0.03 | 0.04 | 0.03 | 0.10 |

| 1100 | 99.00 | 0.95 | 0.05–0.20 | 0.05 | 0.05 | 0.10 | 0.05 | 0.15 |

High aluminum content ensures excellent corrosion resistance and reflectivity, while trace elements fine‑tune mechanical strength and processing behavior.

Applications across the traffic infrastructure

Using these alloys, manufacturers can cover virtually the whole spectrum of static traffic control:

Highway directional signs and gantry boards

Large 1100 or 1060 plates in H14/H24 for stiffness, paired with high‑grade reflective film.Urban regulatory and warning signs

Mid‑thickness 1050 or 1100, easily punched and flanged, providing robust yet lightweight panels.Temporary and construction‑zone signs

Thinner coils, often in softer tempers for rapid forming and lower cost; 1050 and 1060 are popular choices.Street name, parking, and information plates

Smaller sizes favor 1050 or 1060 for easy forming and clean print surfaces.

By adjusting thickness, alloy and temper, a sign maker can standardize on a few coil types and still cover a wide variety of use cases.

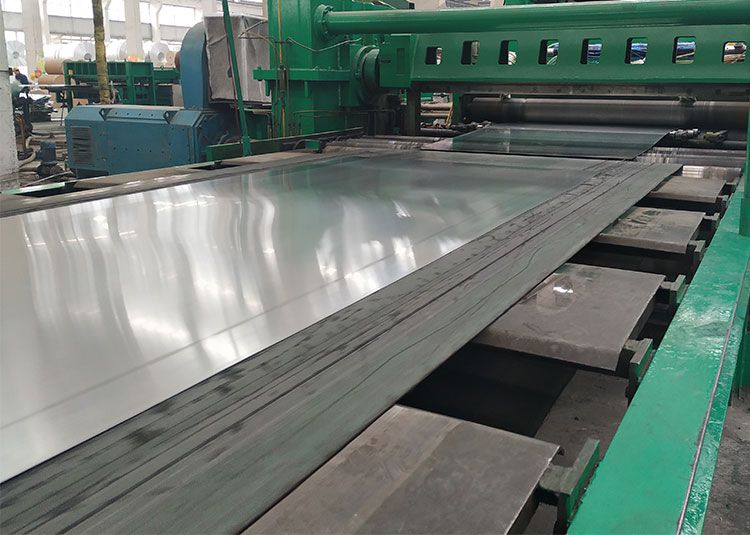

From coil to finished sign: an integrated material story

The lifecycle of a traffic sign plate coil is straightforward but technically demanding:

- Coil rolling with tight thickness tolerance and flatness control

- Surface treatment (degreasing, brushing, chemical conversion) to ensure strong bond with films and coatings

- Continuous or batch cutting, punching, and bending according to sign design

- Application of retroreflective sheeting and legend graphics

- Inspection for flatness, edge quality, and surface defects

Throughout this chain, the predictable behavior of 1100, 1050, 1060 and 1070 is what allows manufacturers to run stable, high‑yield production.

Choosing the right aluminum plate coil for your project

For buyers and specifiers, a practical approach is to define:

- Sign size and structural demands

- Required forming operations and bending radii

- Environmental exposure (urban, coastal, industrial)

- Compatibility with reflective films and printing systems

- Relevant national or project standards

Then, match these requirements to alloy–temper–thickness combinations. For many road authorities, the final choice often converges on 1050/1060/1100 in H14 or H24 within 1.0–2.5 mm thickness.

By how 1100, 1050, 1060 and 1070 behave as functional materials rather than just alloy numbers, traffic sign manufacturers can design panels that are lighter, longer‑lasting and more cost‑efficient, while ensuring that the message on the road remains visible and reliable for years.