Marine aluminum I beams are engineered solutions specifically crafted for the marine industry, providing robust support for boat decks and frames. These structural components are characterized by their excellent strength-to-weight ratio, corrosion resistance, and adaptability in harsh marine environments. With a range of applications from solid boat foundations to offshore structures, our marine aluminum I beams is know in reliability and performance.

Features

Exceptional Strength-to-Weight Ratio

Thanks to advanced aluminum alloys, our marine I beams provide superior strength without the added bulk, which translates into lighter boats and enhanced maneuverability.

Corrosion Resistance

Marine environments are often characterized by high humidity and salinity. Aluminum alloys used in our I beams function as dually-designed elements, resisting pitting, which is imperative to ensure durability over time.

Easy Fabrication

The aluminum structure enables straightforward fabrication through welding, machining, and cutting processes, thus enhancing versatility in design adjustments and custom fabrications.

Compact Design

The unique I shape enhances load distribution, providing optimum support in confined spaces and under rigs that endure significant environmental stress.

Reduced Maintenance

With inherent properties that shield from corrosion and degradation, marine aluminum I beams require minimal maintenance compared to steel counterparts.

Applications

Marine aluminum I beams are versatile components ideal for a variety of nautical applications, including but not limited to:

- Heavy-duty decks for yachts and commercial fishing vessels

- Support structures for docks and marinas

- Trawl and other slipper hull boat frames.

- Shipbuilding frameworks in alignment with National Marine Manufacturers Association standards.

- Bridges and linkways overseeing water channels.

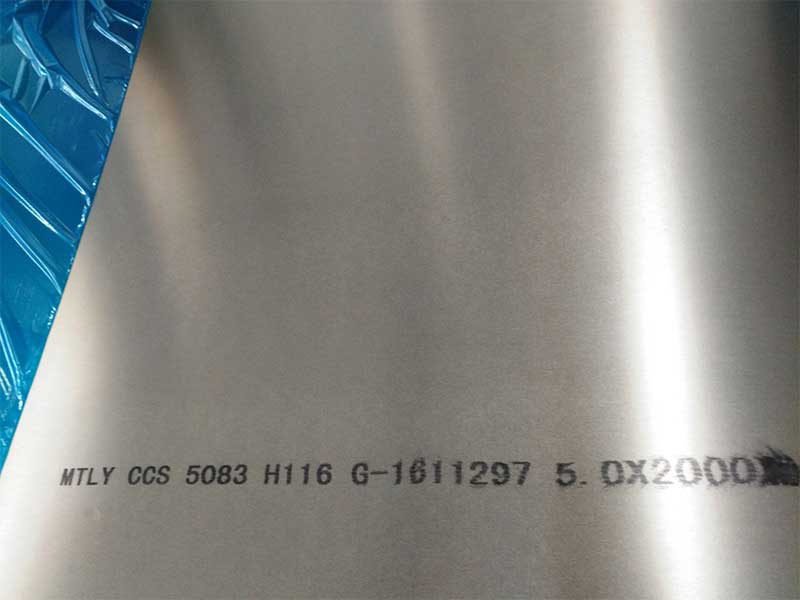

Chemical Composition

The standard chemical composition for our high-quality marine aluminum I beams is outlined below. This emphasizes the typical alloy used, which is often the 6005 or 6061 series.

| Alloy Type | Al (%) | Si (%) | Fe (%) | Cu (%) | Mg (%) | Mn (%) | Zn (%) | Others (%) |

|---|---|---|---|---|---|---|---|---|

| 6061 | 95.85 | 0.6 | 0.3 | 0.15 | 0.9 | 0.15 | 0.25 | Remaining (Cr, Ti) |

| 6005 | 95.6 | 0.6 | 0.65 | 0.05 | 0.6 | 0.15 | 0.25 | Remaining (Fe, Mn) |

Technical Specifications

For a thorough of the performance capabilities and characteristics of our I beams, refer to the specifications table below:

| Attribute | Specifications |

|---|---|

| Alloy Designation | 6061-T6, 6005-T5 |

| Density (g/cm³) | 2.7 |

| Yield Strength (MPa) | 240-310 |

| Tensile Strength (MPa) | 310-330 |

| Elongation (%) | 10-20 |

| Modulus of Elasticity (GPa) | 68 |

| Corrosion Resistance | High (to marine standards) |

| Surface Finish | Mill Finish, Anodized available |

| Standard Lengths Available | 20 ft average, custom lengths possible |