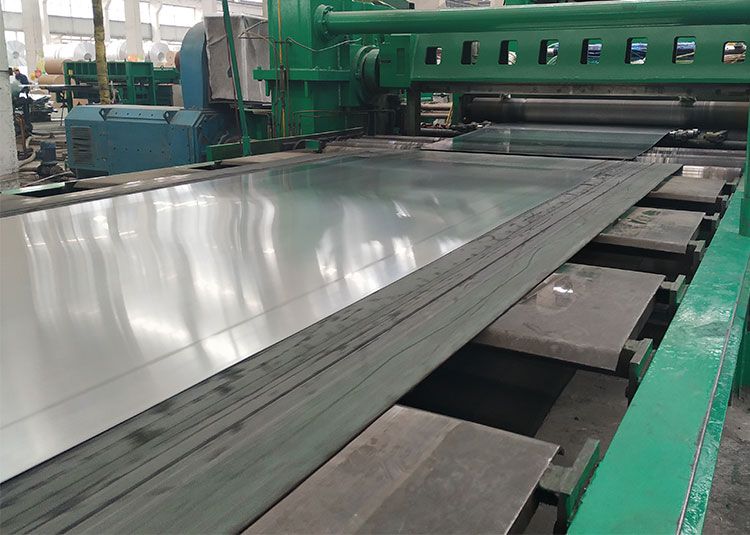

Aluminum sheets have found widespread applications across multiple industries due to their lightweight, corrosion-resistant, and malleable properties. Among the various grades specified by ASTM (American Society for Testing and Materials) standards, 3003, 3004, and 3105 alloys are among the most popular for various applications.

Features

General Characteristics

- Malleability: Alloys 3003, 3004, and 3105 have excellent malleability, making them easy to fabricate and form into complex shapes without breaking.

- Corrosion Resistance: These aluminum sheets exhibit strong resistance against environmental attacks, adding durability to products made from these materials.

- Weight-to-Strength Ratio: Lightweight properties ensure applications can benefit from reduced transportation costs and easier handling.

Applications

Aluminum sheets of these grades find applications in various industries:

- Food and Chemical Handling: 3003 aluminum sheets are often used in the manufacturing of utensils and cooking equipment because they are non-toxic and resistant to corrosive substances.

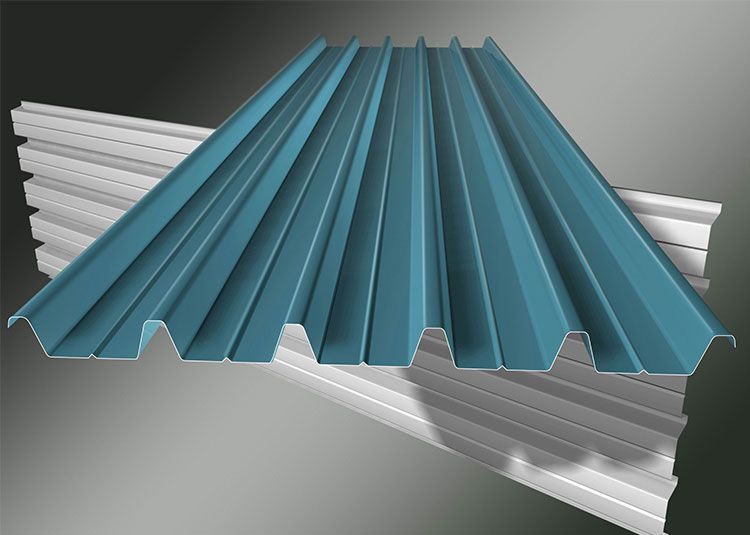

- Architectural Products: 3105 and 3004 alloys frequently serve in siding, roof panels, and window frames due to their flexibility and aesthetic finish.

- Automotive and Manufacturing: Alloys in this range are utilized for fabricating parts that require additional formability.

Benefits

- Easy to weld and join steam.

- Lower production costs without sacrificing essential quality aspects.

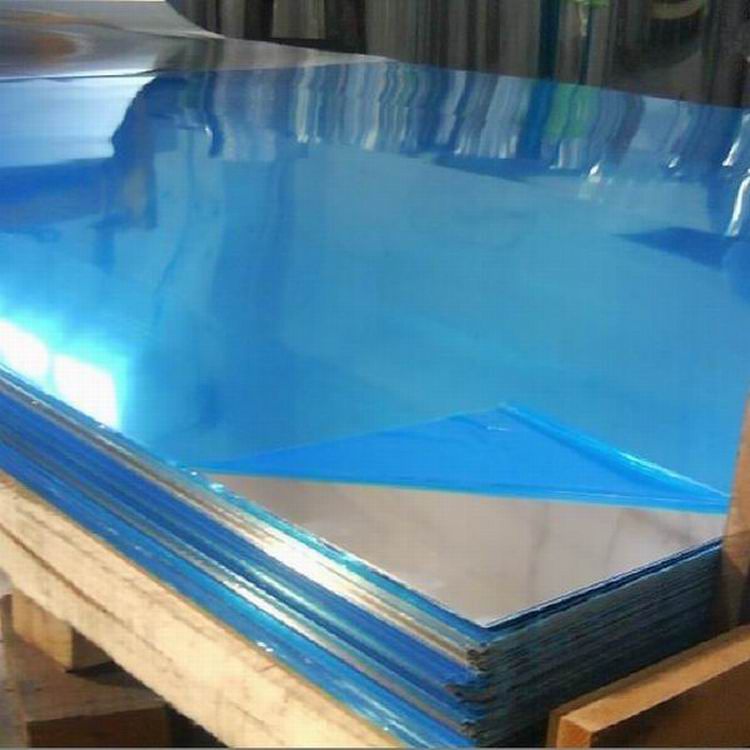

- Adhesive coatings achieve excellent adhesion due to a strong aluminum surface.

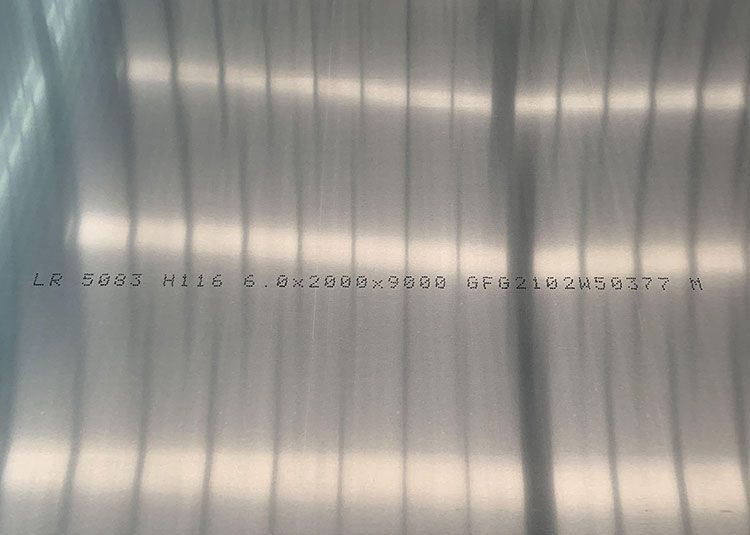

Technical Specifications

Below is a table summarizing crucial technical specifications for ASTM 3003, 3004, and 3105 aluminum sheets:

| Parameter | 3003 | 3004 | 3105 |

|---|---|---|---|

| Alloy Type | Aluminum - Manganese | Aluminum - Manganese and Magnesium | Aluminum - Manganese |

| Temper | H14, H16, H18 | H19, H22, H24 | H24, H26 |

| Thickness Range | 0.020 - 0.190 in | 0.015 - 0.120 in | 0.032 - 0.120 in |

| Width Range | Up to 72 in | Up to 72 in | Up to 72 in |

| Length | Custom cut or standard up to 144 in | Custom cut or standard up to 144 in | Custom cut or standard up to 144 in |

| Finish | Mill finish, Glossy, Anodized | Mill finish, Painted | Fine Resin Coated |

Chemical Composition

| Grade | Al (% min) | Cu (% min) | Fe (% min) | Si (% max) | Mg (% min) | Mn (% min) | Zn (% max) | Others |

|---|---|---|---|---|---|---|---|---|

| 3003 | 97.0 | 0.05-0.20 | 0.70-1.00 | 0.10 | 0.05-0.20 | 1.0-1.5 | 0.10 | Each, 0.05 max, Total, 0.15 max |

| 3004 | 96.8 | 0.90-1.20 | 0.40-0.80 | 0.04 | 0.40-0.90 | 1.0-1.5 | 0.20 | Each, 0.05 max, Total, 0.15 max |

| 3105 | 98.0 | 0.10-0.30 | 0.15-0.40 | 0.10 | 0.05-0.20 | 0.30-0.60 | 0.10 | Each, 0.05 max, Total, 0.15 max |

Performance Metrics

To aid customers in their selection process, here are the tensile strength benchmarks of these aluminum sheets:

| Grade | Tensile Strength (ksi) | Yield Strength (ksi) | Elongation (%) | Hardness (BHN) |

|---|---|---|---|---|

| 3003 | 15 to 20 | 10 to 15 | 16-25 | 60-105 |

| 3004 | 20 to 25 | 15 to 20 | 17-28 | 80-130 |

| 3105 | 22 to 26 | 15 to 19 | 22-27 | 70-120 |