Features

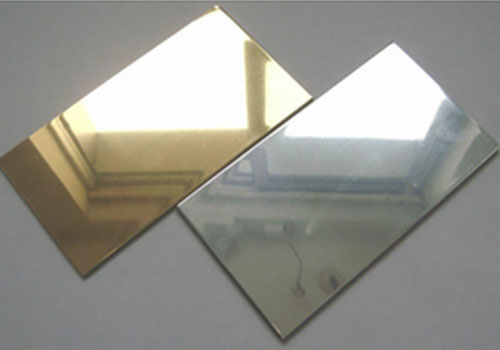

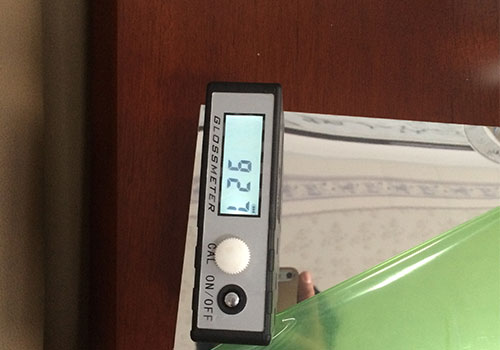

High Reflectivity: The polished surface allows for high reflective capabilities, making it ideal for decorative purposes.

Excellent Corrosion Resistance: This alloy is capable of excellent performance in corrosive environments, prolonging the lifespan of the products made from it.

Low Density: With low density, this alloy is lightweight while still maintaining adequate strength.

Good Workability and Formability: It allows for precision engineering and complex shapes, catering to custom projects easily.

Non-Toxic: Safe for use in food transparency and handling applications, thanks to its health-friendly properties.

Technical Specifications

To consider the Mirror 3003 H14 Aluminum Sheet for particular applications, it’s essential to review its technical specifications, which are detailed in the table below:

| Specification | Value |

|---|---|

| Alloy Designation | 3003 |

| Temper | H14 |

| Thickness Range | 0.2 mm to 10 mm |

| Width Range | Up to 1500 mm |

| Length Range | Custom cut available |

| Surface Finish | Mirror polished |

| Density | 2.73 g/cm³ |

| Melting Point | 660 °C (1220 °F) |

Chemical Composition

The composition of 3003 H14 aluminum alloy greatly influences its mechanical characteristics. The following table summarizes the elements present, including their proportions:

| Element | Percentage (%) |

|---|---|

| Aluminum (Al) | 96.99 - 98.65 |

| Copper (Cu) | 0.12 - 0.20 |

| Manganese (Mn) | 1.0 - 1.5 |

| Silicon (Si) | 0.6 max |

| Iron (Fe) | 0.7 max |

| Zinc (Zn) | 0.1 max |

| Other | 0.15 max each; Total 0.25 max |

Mechanical Properties

The following properties define how the material performs under mechanical stress, providing insight into its structure:

| Property | Value |

|---|---|

| Yield Strength (MPa) | 110 MPa |

| Ultimate Tensile Strength (MPa) | 190 MPa |

| Elongation (%) | 20-25% |

| Hardness (Brinell) | 60 HB |

Applications

With its distinctive characteristics, the Mirror 3003 H14 Aluminum Sheet is widely used in various applications spanning several industries:

- Interior Decoration: Ideal for decorative elements, wall paneling, and ceilings where reflectiveness is desired.

- Architectural Components: Frequently used in building facades and support structures particularly in aesthetic projects.

- Signage: Used for making durable and reflective signs, providing visibility even in low-light conditions.

- Marine & Automotive: Utilize in boat components and vehicle accessories where weight reduction without compromising performance is needed.

- Air Conditioning and Refrigeration: Applied in equipment casing and panels due to its moisture resistance.

Benefits

- Durability: Resistant to rust, rot, and various environmental conditions.

- Cost-Effective: Lower price point compared to high-grade alloys while still maintaining usability.

- Appearance: Bright, polished finish enhances aesthetic appeal; increasingly applicable for contemporary designs.

- Energy Efficiency: Lightweight design benefits reduced fuel consumption in transport applications.