Mirror polished aluminum plate is a high-grade aluminum product characterized by its exceptionally smooth and reflective surface, resembling a mirror. Its striking appearance alongside excellent mechanical and chemical properties makes it a highly sought material across various industries.

What is Mirror Polished Aluminum Plate?

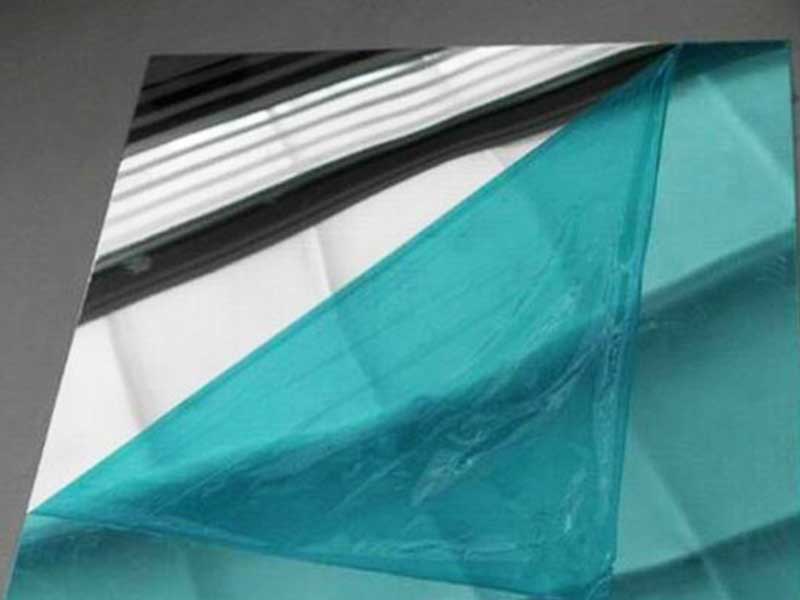

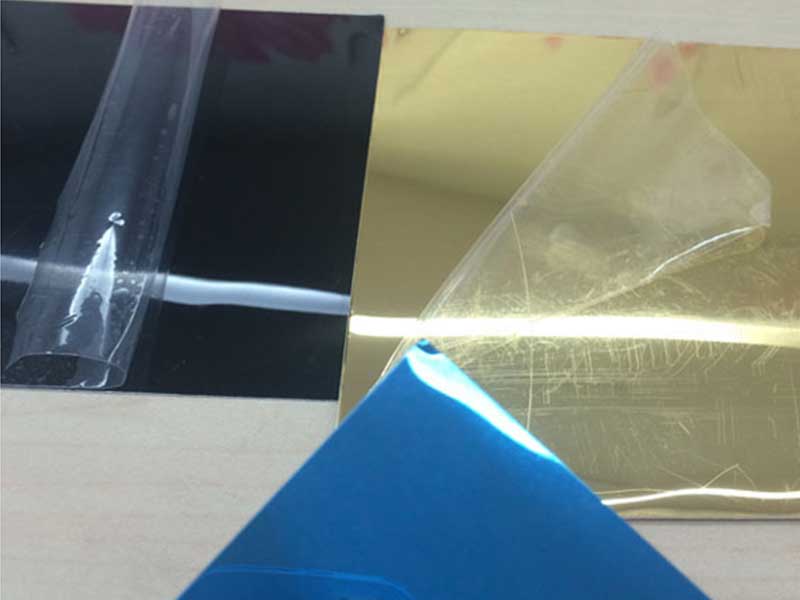

A mirror polished aluminum plate undergoes a precision surface finishing process through progressively finer abrasives and polishing compounds. This results in a highly reflective surface with a glossy finish that greatly exceeds standard aluminum sheets in aesthetics and smoothness. The process not only enhances appearance but often improves surface corrosion resistance due to the densification and sealing effects of polishing.

Functions & Advantages

- Superior Aesthetic Appeal: Its brilliant mirror-like reflection offers unsurpassed visual enhancement for decorative usages.

- Corrosion Resistance: Polishing helps reduce microcrevices where corrosion could initiate, boosting surface durability.

- Lightweight and High Strength: Retains core aluminum advantages, being lightweight yet mechanically strong in certain alloy temper conditions.

- Easy to Fabricate: It can be cut, formed, or welded with usual techniques with minimal post-processing.

- Reflectivity and Thermal Conductivity: High reflectivity suitable in heat management and equipment enclosures requiring thermal control.

Typical Applications of Mirror Polished Aluminum Plates

Because of a combination of durability and deluxe surface quality, mirror polished aluminum plates find usage in many fields:

| Industry | Typical Applications |

|---|---|

| Architecture | Interior decoration, ceiling panels, façade cladding |

| Automotive | Trim parts, decorative moldings, reflectors |

| Electronics | Control panels, casings for devices requiring aesthetics and corrosion resistance |

| Food & Beverage | Food processing equipment, cleanroom wall panels |

| Advertising & Display | Sign Boards, exhibitor displays, reflective signage |

| Aerospace | Lightweight reflective panels, decorative trims |

| Medical Equipment | Hygienic and aesthetics-required surface components |

Technical Specifications and Standards

| Parameter | Typical Values / Range | Reference Standards |

|---|---|---|

| Thickness | 0.3 mm – 6.0 mm | ASTM B209, EN 485 |

| Surface Roughness (Ra) | ≤ 0.02 µm | ISO 4287 |

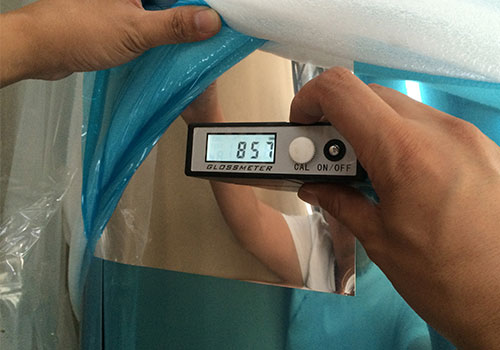

| Reflectivity | ≥ 85% (400–700 nm wavelength light) | Internal QA Test |

| Flatness | ≤ 1.0 mm per 1000 mm dimension | ASTM B209 |

| Dimensional Tolerance | ±0.03 mm for thickness, ±1% width | ASTM B209, GB/T 3880 |

| Color | Metallic Bright Silver | N/A |

Available Alloy Types and Temper Designations

Common alloys for mirror polished aluminum utilize the 1xxx series for purity or 5xxx and 6xxx series for improved strength while maintaining good polishing characteristics:

| Alloy Grade | Temper | Description | Mechanical Traits |

|---|---|---|---|

| 1000 Series (e.g., 1100) | H14, H16 | High purity (>99% Al), excellent corrosion resistance and polishable nature | Good ductility, medium strength |

| 3000 Series (e.g., 3003) | H14 | Manganese-addition improves strength and corrosion resistance | Moderate strength, good workability |

| 5000 Series (e.g., 5052) | H32, H34 | Magnesium-alloyed for higher strength and corrosion resistance | High strength, especially in H34 |

| 6000 Series (e.g., 6061) | T6, T651 | Magnesium + Silicone, extrudable, good finish quality | Good mechanical properties, medium strength |

Chemical Composition of Common Mirror Polished Aluminum Alloys

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Cr (%) | Zn (%) | Ti (%) | Al (%) |

|---|---|---|---|---|---|---|---|---|---|

| 1100 | ≤0.4 | ≤0.4 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.1 | ≤0.1 | ≤0.03 | Bal. |

| 3003 | 0.6–1.2 | ≤0.7 | ≤0.05 | 1.0–1.5 | ≤0.1 | ≤0.1 | ≤0.1 | ≤0.03 | Bal. |

| 5052 | ≤0.4 | ≤0.4 | ≤0.1 | ≤0.1 | 2.2–2.8 | ≤0.15 | ≤0.1 | ≤0.03 | Bal. |

| 6061 | 0.4–0.8 | ≤0.7 | 0.15–0.4 | ≤0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Bal. |

*Balance aluminum rules make the remainder of contents

Mechanical Property Parameters

| Alloy | Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1100 | H14 | 90–110 | 35–50 | ≥10 |

| 3003 | H14 | 130–145 | 95–115 | 10–12 |

| 5052 | H32 | 228–265 | 193–228 | 8–12 |

| 6061 | T6 | 290–310 | 240–270 | 8–12 |

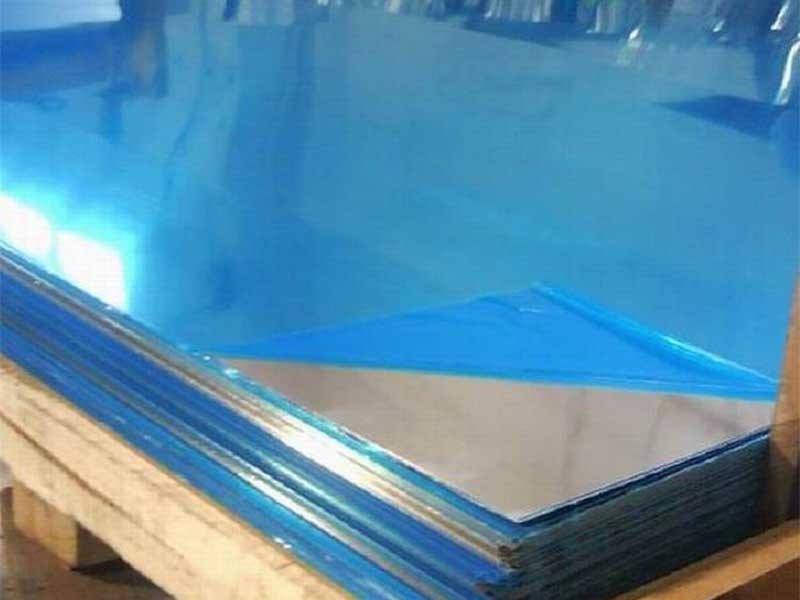

Handling and Maintenance

Mirror polished aluminum plates require careful handling to maintain their surface finish. Signs of abrasion or fingerprint can mar the perfect mirror effect, so the following best practices apply:

- Use soft gloves to handle sheets

- Store in clean, dry environments away from harsh chemicals or abrasives

- Clean the surface using mild detergents and non-abrasive cloths

- Avoid excessive scratching; re-polishing may be required for damaged surfaces

Mirror polished aluminum plates uniquely combine remarkable aesthetic presence with the inherent benefits of aluminum such as lightness, corrosion resistance, and versatile mechanical properties. Serving prominent roles across automotive, architecture, electronics, food processing, and more, they meet strict fabrication and quality standards alongside customization possibilities via alloy selection and tempering.

Their unparalleled visual effect along with reliability in performance makes mirror polished aluminum plates a superior choice for purveyors aiming to pair functionality and stunning design aesthetics seamlessly.

For precision requirements concerning thickness, tolerance, or coatings, consulting dedicated producer catalogs and certifications ensures fully tailored solutions appropriate to specific project/environmental demands.

For further inquiries and customised orders for high-precision mirror polished aluminum plates, contact professional suppliers specializing in advanced aluminum fabrication.