PP Cap Aluminum Foil for Alcohol and Wine Closures: Leak-Proof Packaging and Freshness Lock

In the world of alcohol and wine packaging, the space between the bottle and the consumer is only a few microns thick. That space is filled by a carefully engineered material: PP cap aluminum foil. Designed specifically for alcohol and wine closures, this foil is more than a shiny seal. It is a layered, technical solution that keeps liquids from leaking, prevents aroma loss, and preserves brand integrity from bottling line to final pour.

What is PP Cap Aluminum Foil?

PP cap aluminum foil is a specialized flat-rolled aluminum material used to produce pilfer-proof (PP) closures for alcohol and wine bottles. These are the threaded, often decorated caps seen on spirits, wines, and liquors. The foil becomes the shell of the cap or a internal sealing layer, working with liners and coatings to form a tight, tamper-evident barrier.

Instead of merely being a passive metal wrapper, the foil plays an active role in:

- Preventing leakage during transport and storage

- Blocking oxygen and moisture ingress

- Preserving volatile aromas and alcohol content

- Supporting easy, consistent capping on high-speed lines

- Providing a printable, decorative surface for branding

The most distinctive way to understand PP cap aluminum foil is to see it as an interface material. It touches three critical environments at once:

- The inner liquid (wine or alcohol)

- The bottle neck (glass or sometimes PET)

- The external atmosphere and handling environment

Each side demands something different. The product must be chemically stable to the liquid, mechanically matched to the bottle, and visually appealing and corrosion-resistant on the outside. This triple interface requirement defines the choice of alloy, temper, lacquer, and film.

Instead of thinking of the foil as “just aluminum,” it is more accurate to view it as a controlled composite system: metal core plus functional coatings designed to work under torque, heat, humidity, and long-term storage.

Core Functions in Alcohol and Wine Closures

Leak-proof sealing

The dimensional precision and mechanical strength of PP cap aluminum foil ensure that the thread forming of caps is accurate and stable. Under correct torque, the cap compresses the liner uniformly against the bottle lip, forming a seal that prevents liquid escape even under variations in temperature, pressure, or handling.

Freshness lock

Aluminum provides an almost complete barrier to oxygen, light (especially UV), and moisture. When combined with inner liners and suitable varnishes, the system slows oxidation of wine and maintains the organoleptic profile of spirits. Aroma compounds and alcohol content remain closer to their bottled state for longer periods.

Tamper evidence and brand protection

PP caps made from the foil often incorporate tear bands or breakable rings. The controlled ductility and fracture behavior of specific tempers ensure that once opened, the closure cannot be resealed without visible damage. For premium spirits and brand-sensitive wines, this is a quiet but powerful anti-counterfeit feature.

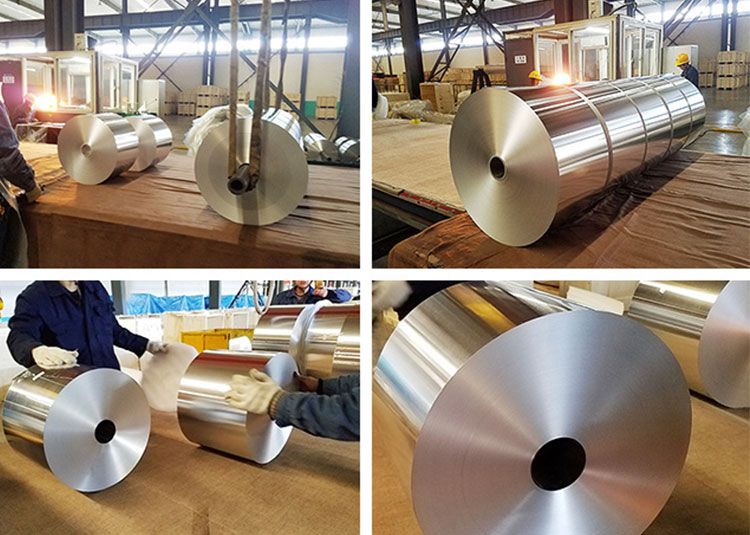

Mechanical reliability on bottling lines

The foil has to be strong enough to withstand multi-step processes: slitting, deep drawing, threading, knurling, color printing, and perforation. Alloy and temper choices are tuned to avoid cracking, pinholes, or delamination. For bottlers, this translates to lower downtime and consistent torque values.

Surface aesthetics

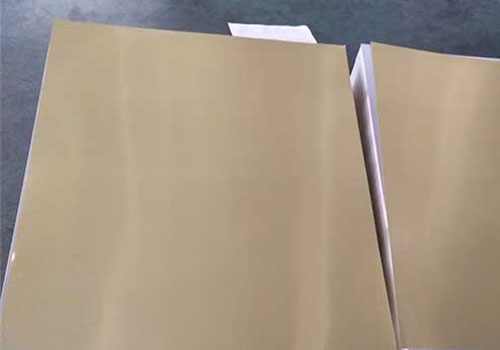

Printing inks, embossing, and lacquers all rely on a stable, smooth foil surface. From matte vintage styles to high-gloss metallic finishes, the controlled roughness and coating chemistry of PP cap foil act as the foundation of visual identity on the shelf.

Typical Alloys and Temper Conditions

For alcohol and wine PP caps, non-heat-treatable, corrosion-resistant alloys are preferred, with easy formability and good coating adhesion. Common choices include:

- Alloy 8011: very popular for PP caps due to excellent formability, good strength in H14 or H16 tempers, and good lacquer adhesion

- Alloy 3105: used when slightly higher strength and better corrosion resistance are needed

- Alloy 1050 / 1060: nearly pure aluminum, used for specific applications requiring very good deep-drawing behavior

The temper indicates how the foil has been work-hardened:

- H14: half-hard, offering a balance between strength and formability; suitable for standard pilfer-proof caps

- H16: harder, with higher strength where more rigidity or thread strength is needed

- H24 / H26: used in some designs requiring improved buckle resistance

Typical thickness range for PP cap aluminum foil is approximately 0.18–0.27 mm, sometimes slightly outside this window for custom applications. Thickness, alloy, and temper are matched to cap height, neck design, and bottle type.

Technical Parameters and Implementation Standards

To perform as a reliable closure component, PP cap aluminum foil is manufactured and evaluated under both international and customer-specific standards. While exact figures may be tuned per project, common parameter targets include:

- Thickness tolerance: narrow tolerance (often ±0.005–0.01 mm) to ensure uniform forming and consistent cap torque

- Tensile strength: generally in the range of about 110–180 MPa (depending on alloy and temper) for adequate strength without sacrificing formability

- Elongation: controlled to avoid cracking during deep drawing and threading; typically above 6–10% in longitudinal direction for cap stock

- Surface quality: free from pinholes, rolling defects, oil spots, and scratches that could compromise barrier performance or printing

Internationally, many producers align with or reference:

- EN standards for aluminum strip and sheet (such as EN 573 for chemical composition, EN 485 for mechanical properties)

- ISO-based quality systems, including ISO 9001 for production consistency and ISO 14001 for environmental management

- Food-contact regulations such as EU Regulation (EC) No 1935/2004 and relevant FDA guidelines when lacquers or coatings contact the product

Color coatings and inside lacquers are often tested for solvent resistance, adhesion (cross-hatch tests), flexibility (bend tests), and migration behavior, particularly if in direct or indirect contact with alcohol.

Chemical Properties and Typical Composition

PP cap aluminum foil alloys are chosen for their corrosion resistance, low reactivity with alcohol, and compatibility with lacquers. The table below shows typical composition ranges for two widely used alloys.

| Property / Element | Alloy 8011 (wt.%) | Alloy 3105 (wt.%) |

|---|---|---|

| Aluminum (Al) | Balance | Balance |

| Silicon (Si) | 0.5 – 0.9 | ≤ 0.6 |

| Iron (Fe) | 0.6 – 1.0 | ≤ 0.7 |

| Copper (Cu) | ≤ 0.1 | ≤ 0.3 |

| Manganese (Mn) | ≤ 0.2 | 0.3 – 0.8 |

| Magnesium (Mg) | — | 0.2 – 0.8 |

| Zinc (Zn) | ≤ 0.1 | ≤ 0.4 |

| Titanium (Ti) | ≤ 0.08 | ≤ 0.1 |

| Other (each) | ≤ 0.05 | ≤ 0.05 |

| Other (total) | ≤ 0.15 | ≤ 0.15 |

| Corrosion behavior | Good in neutral media | Good, with Mn/Mg aid |

These compositions are structured to:

- Provide adequate strength and formability through controlled amounts of Fe, Si, Mn, and Mg

- Maintain resistance to stress corrosion cracking and general corrosion in typical alcohol and wine environments

- Support stable oxide film formation on the surface, which improves lacquer adhesion and long-term durability

Applications Across Alcohol and Wine Segments

Wine closures

For still wines, PP cap aluminum foil is used in long-skirted screw caps that aim to replace natural cork while maintaining or improving oxygen barrier performance. Inside liners can be engineered to control oxygen transmission rates, working with the aluminum shell to fine-tune shelf life and flavor development.

Spirits and liquors

High-proof products like vodka, whisky, gin, and rum demand reliable leak-proof seals due to low surface tension and high solvent power. The compatibility of coatings with ethanol is critical. PP cap foil with robust lacquer systems prevents corrosion and avoids off-tastes while delivering sharp, tamper-evident pilfer bands.

Flavored beverages and liqueurs

These often contain sugars, acids, and flavors that can be more aggressive toward packaging materials. Balanced alloy choice plus protective lacquer layers ensure that the foil resists pitting and maintains appearance even in humid or variable climates.

Premium and decorative caps

Premium brands rely heavily on visual differentiation. Here, the flatness and controlled roughness of the foil allow for high-precision printing, hot stamping, embossing, and complex colors. The metal’s inherent reflectivity enhances metallic inks and emboss textures, sending a quality signal before the bottle is even opened.

From Metallurgy to Marketing: Why Details Matter

Every technical choice in PP cap aluminum foil—its alloy, temper, thickness, coating system, and standards compliance—has practical consequences:

- Better leak-proof performance means fewer returns and complaints.

- Stable chemical behavior protects taste, color, and aroma.

- High-quality printing and surfaces strengthen brand recognition.

- Consistent mechanical properties keep bottling lines efficient and predictable.

For alcohol and wine producers, the foil as a sophisticated interface material, rather than a mere commodity, opens the door to better closure design, longer shelf life, and a more controlled consumer experience.

PP cap aluminum foil is where engineering precision and sensory quality quietly meet, sealing in freshness and sealing up risk—one cap at a time.