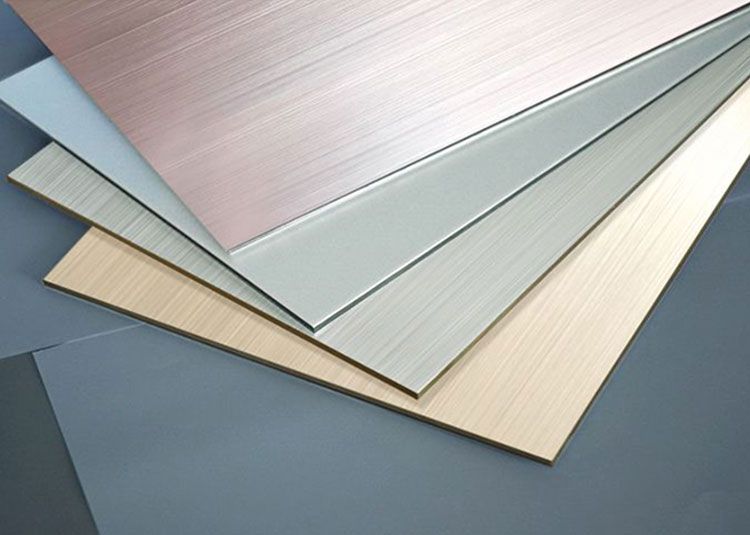

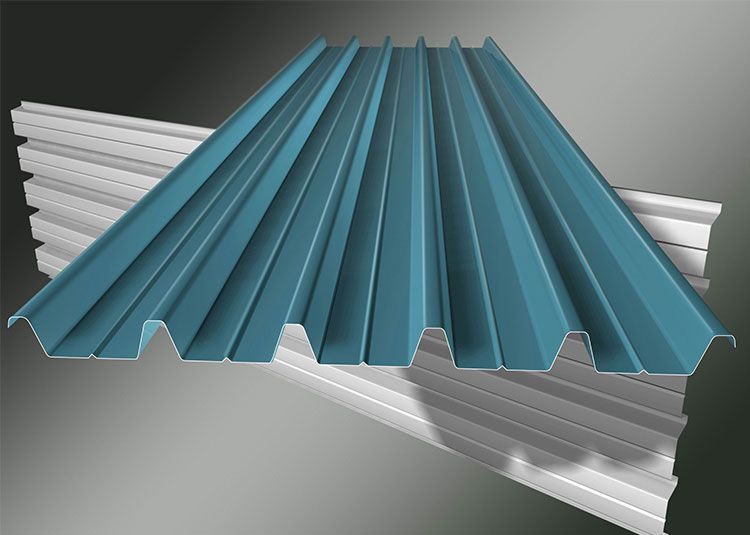

3003, 3004, 3A21, and 3105 aluminum plates belong to the Al-Mn (3xxx) alloy family, widely chosen for their balanced combination of corrosion resistance, formability, moderate strength, and cost efficiency. These grades are non-heat-treatable, meaning their strength is mainly achieved through cold working (strain hardening) and controlled annealing. For customers, this translates into dependable performance in fabrication-heavy applications such as cladding, roofing, tanks, vehicle panels, ducting, and general sheet-metal structures-especially where long service life and clean surface appearance matter.

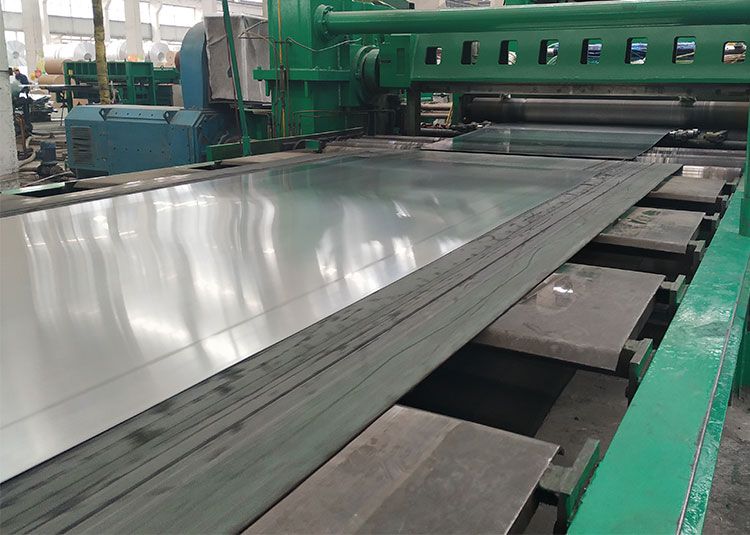

From a production standpoint, these alloys are typically supplied as hot-rolled plate or cold-rolled plate with stable flatness, uniform mechanical properties, and excellent finishing compatibility for coating, anodizing (limited decorative effect for 3xxx), lamination, and painting. Among them, 3004 offers a step up in strength due to Mg addition, while 3105 is a popular choice for coated building products and general-purpose formed parts. 3A21 is a commonly referenced Chinese designation with performance comparable to 3003 in many applications.

Features at a Glance

| Feature | What it means for your project |

|---|

| Excellent corrosion resistance | Long life in humid, industrial, and mild marine atmospheres |

| High formability and ductility | Reliable bending, roll forming, drawing, and spinning |

| Moderate strength, weldable | Stronger than pure aluminum, easy to join with common methods |

| Great surface for coating | Strong adhesion for PVDF/PE paint systems, especially in 3105 |

| Non-heat-treatable stability | Predictable behavior in forming; no quench distortion concerns |

| Good thermal conductivity | Useful for HVAC, heat shields, and housings |

Alloy Positioning and Typical Use Fit

| Alloy | Practical positioning | Common "why this alloy" reason |

|---|

| 3003 | The classic general-purpose Al-Mn plate | Best overall value, excellent forming and corrosion resistance |

| 3004 | Higher-strength 3xxx with Mg | Better dent resistance and strength for panels and drawn parts |

| 3A21 | Similar family option widely used in Asia | Comparable to 3003 for tanks, weldments, formed parts |

| 3105 | Coated building-product workhorse | Excellent for color-coated sheets, cladding, roofing, trims |

Typical Applications

| Industry | Typical parts | Recommended grades |

|---|

| Building & construction | Roofing, wall cladding, facades, rainwater goods, flashing, trims | 3105, 3003 |

| Transportation | Interior panels, body parts (non-structural), liners, covers | 3004, 3003 |

| HVAC & insulation | Ducting, insulation jacketing, housings | 3003, 3105 |

| Storage & containment | Fuel/oil tanks, water tanks, chemical cabinets (mild media) | 3003, 3A21 |

| General fabrication | Enclosures, brackets, covers, signage baseplate | 3003, 3105 |

| Cookware & drawn parts | Deep-drawn containers, shells (application-dependent) | 3004, 3003 |

Chemical Composition (Typical Limits, wt.%)

Values vary slightly by standard (ASTM, EN, GB). Confirm exact compliance for your target specification.

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Others (each/total) | Al |

|---|

| 3003 | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.0–1.5 | ≤0.05 | ≤0.10 | - | ≤0.05/≤0.15 | Balance |

| 3004 | ≤0.30 | ≤0.70 | ≤0.25 | 1.0–1.5 | 0.8–1.3 | ≤0.25 | - | ≤0.05/≤0.15 | Balance |

| 3A21 | ≤0.60 | ≤0.70 | ≤0.20 | 1.0–1.6 | ≤0.05 | ≤0.10 | - | ≤0.05/≤0.15 | Balance |

| 3105 | ≤0.60 | ≤0.70 | ≤0.30 | 0.3–0.8 | 0.2–0.8 | ≤0.40 | ≤0.20 | ≤0.05/≤0.15 | Balance |

Temper and Mechanical Properties (Typical Guidance)

3xxx alloys are strengthened by work hardening. Exact properties depend on thickness, processing route, and standard. Use this table for selection guidance rather than final design values.

| Temper | Description | Typical use scenario |

|---|

| O (Annealed) | Maximum ductility | Deep drawing, tight bending radii, complex forming |

| H12 / H14 | Light to medium strain hardened | General forming, panels requiring better stiffness |

| H16 / H18 | Higher strain hardened | Higher dent resistance, flatter panels, less forming allowance |

| H24 | Stabilized (partially annealed after hardening) | Better formability than H18 with stable properties |

| H32 / H34 | Strain hardened + stabilized | Coated building sheets where stability matters |

Indicative tensile behavior (relative):

| Alloy | Relative strength | Relative formability | Notes |

|---|

| 3003 | Medium-low | Excellent | Best "all-around" fabricator's choice |

| 3004 | Medium | Very good | More strength due to Mg; good for drawn parts |

| 3A21 | Medium-low | Excellent | Often selected for weldments and tanks |

| 3105 | Medium-low to medium | Very good | Strong performance in coated and roll-formed products |

Dimensional and Technical Specifications (Typical Supply Range)

Supply range varies by mill capability. If you share thickness/width/length and temper, a tighter datasheet can be issued.

| Item | Typical range / option |

|---|

| Product form | Hot-rolled plate, cold-rolled plate, cut-to-length sheet |

| Thickness | 0.5–200 mm (common plate range 2–50 mm) |

| Width | 1000–2500 mm (wider on request) |

| Length | 2000–8000 mm (cut-to-length available) |

| Flatness | Controlled via leveling/stretching; critical-flatness available |

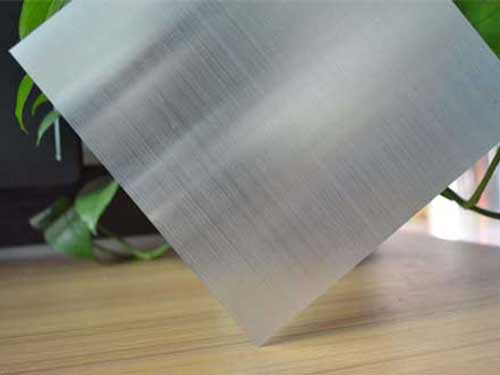

| Surface finish | Mill finish, one-side film, brushed (by request), coated substrate |

| Edge | Mill edge, trimmed edge |

| Standards (common) | ASTM B209, EN 485, GB/T as applicable |

| Joining | MIG/TIG welding, riveting, adhesive bonding (process dependent) |

Processing and Fabrication Notes

| Process | Performance of 3xxx plate | Practical recommendation |

|---|

| Bending | Very good (best in O, H24) | Use larger radii for H18/H34 to avoid edge cracking |

| Deep drawing | 3003/3004 perform strongly | Choose O temper for severe draws; manage lubrication and die radius |

| Welding | Generally excellent | Use suitable filler (commonly 1xxx/4xxx/5xxx depending on service); clean oxide thoroughly |

| Machining | Fair | Use sharp tools; consider coolant and chip control |

| Surface coating | Excellent base | 3105 is widely used for PE/PVDF color coating lines |

| Corrosion behavior | Very good in atmospheric exposure | Avoid galvanic coupling with copper/steel without isolation |

Why Customers Choose These Plates

| Customer need | Best fit among 3003 / 3004 / 3A21 / 3105 |

|---|

| Lowest total cost with dependable forming | 3003 or 3A21 |

| Higher strength without moving to 5xxx | 3004 |

| Color-coated building products and trims | 3105 |

| Tanks, ducting, general fabrication with welding | 3003 or 3A21 |

Ordering Tips (What to Specify)

| Parameter | What to provide |

|---|

| Alloy and temper | Example: 3105-H24, 3004-H14, 3003-O |

| Thickness × width × length | Include tolerances if critical |

| Standard | ASTM/EN/GB requirement |

| Surface | Mill finish, protective film, coating substrate requirement |

| Application notes | Forming severity, welding, outdoor exposure, coating system |

3003, 3004, 3A21, and 3105 aluminum plate are versatile 3xxx-series Al-Mn alloys known for excellent corrosion resistance, strong formability, and reliable weldability. 3003 and 3A21 are cost-effective choices for tanks, ducting, and general fabrication; 3004 adds higher strength for panels and drawn parts; 3105 is widely used for roofing, cladding, and color-coated building sheets. Available in O and H tempers with broad thickness and size ranges, these aluminum plates offer stable processing performance for bending, forming, and coated applications across construction, transportation, HVAC, and industrial markets.