3003 H14 Checkered Aluminum Plate: The "Everyday Workhorse" with a Grip

When people talk about aluminum tread plate, the conversation often starts with pattern and thickness. But the real story of a 3003 H14 checkered aluminum plate is how it behaves in the real world: how it takes footsteps, water, dust, greasy air, impact, and time-then keeps its shape and appearance with minimal fuss. From a practical viewpoint, this material sits in a sweet spot where corrosion resistance, formability, and anti-slip surface performance meet a cost that makes sense for everyday industrial and commercial use.

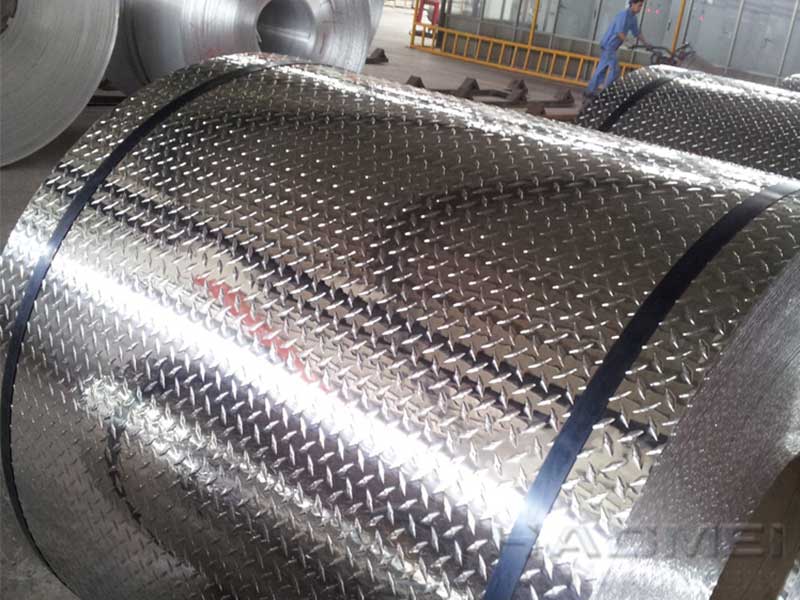

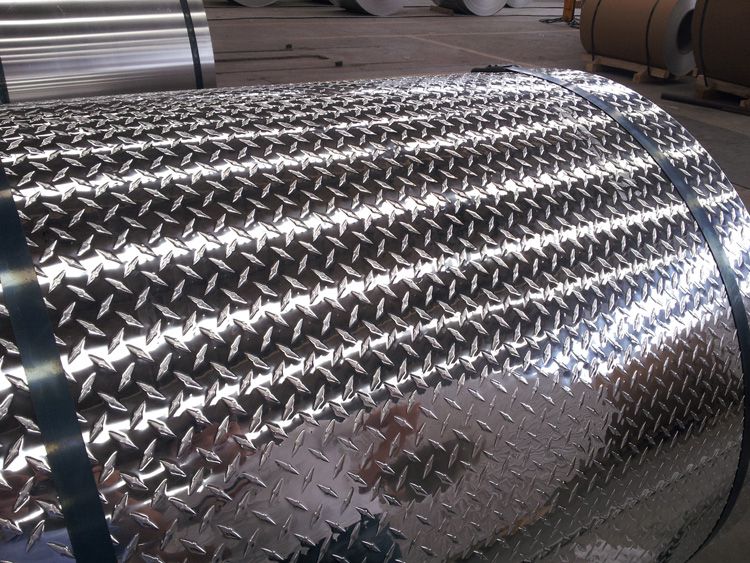

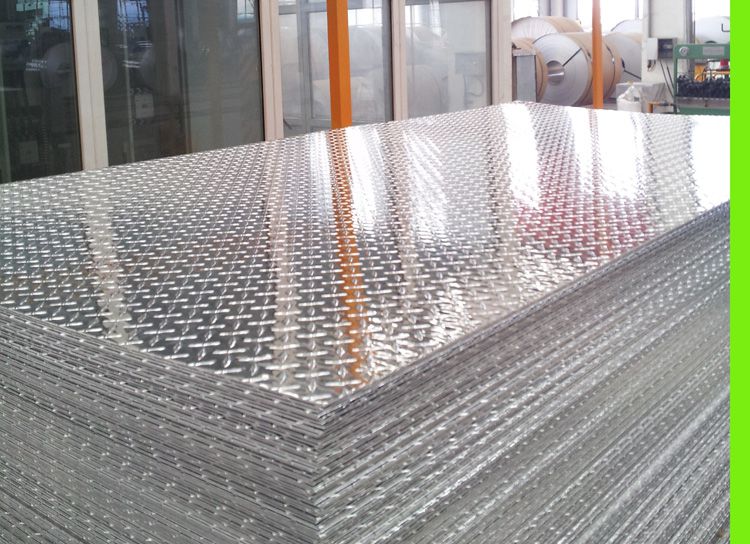

Rather than thinking of it as "just a sheet with diamonds," it helps to see 3003 H14 checkered plate as a surface solution engineered into the metal itself. The raised pattern is not a coating that peels or a paint that fades first; it's part of the plate, giving traction and stiffness while keeping the natural advantages of aluminum.

What "3003 H14" Really Means in Daily Use

3003 is an aluminum-manganese alloy. Manganese is the quiet contributor here: it improves strength over pure aluminum while maintaining excellent workability and strong corrosion resistance. That's why 3003 is often chosen for environments where the plate will be exposed to humidity, mild chemicals, road splash, or general outdoor conditions.

H14 is the temper designation that explains the plate's "personality." H14 indicates the material is strain hardened to a half-hard condition. In simple terms, it's stronger and more dent-resistant than fully soft material, but still formable enough for bending, cutting, and fabrication. For many customers, H14 feels like the most balanced choice: sturdy without being stubborn.

The checkered pattern adds more than grip. It also increases rigidity slightly, so the plate can feel more solid underfoot compared to a flat sheet of the same thickness.

Checkered Patterns: Traction Meets Visual Order

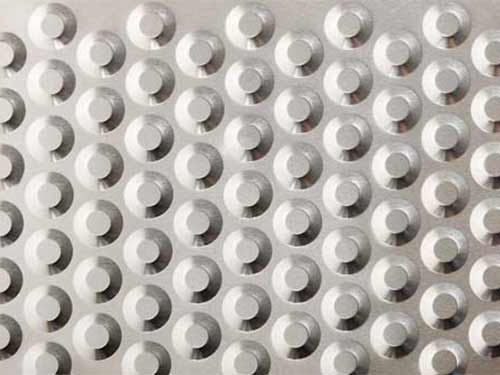

Checkered aluminum plate is commonly supplied as diamond tread (often called five-bar in some markets). The raised bars improve traction and help mask minor wear. In high-traffic areas, that matters: a surface that looks "presentable" longer can be as valuable as pure mechanical performance.

Common applications include:

- Vehicle floors, trailer decks, truck step plates

- Walkways, platforms, mezzanines, stair treads

- Toolboxes, protective wall panels, ramps

- Decorative-industrial interior finishes where "clean and tough" is the aesthetic

If you're selecting for foot traffic and general industrial contact, 3003 H14 is frequently the pragmatic, widely available option.

Typical Parameters Customers Care About

Because different regions and mills vary, real purchasing decisions often come down to a handful of parameters. Here's what buyers typically specify:

Thickness

Common base thickness ranges from 1.0 mm to 6.0 mm, with heavier gauges available depending on rolling capability. For tread plate, clarify whether thickness refers to the base metal or overall including the raised pattern. Many suppliers quote base thickness and treat pattern height as additional.

Pattern height

Often around 0.8 mm to 1.5 mm, depending on pattern style and mill tooling.

Sheet and coil formats

- Sheets are common for flooring, steps, and panels

- Coils are useful for large-scale fabrication and stamping workflows

Surface finish

Mill finish is typical, but brushed, anodized, or coated finishes are possible when appearance matters.

Weight considerations

Aluminum's lower density makes handling easier and reduces structural dead load, especially compared with steel tread plate.

Implementation Standards and Common References

In international trade, 3003 H14 checkered aluminum plate is frequently supplied to recognized standards. Availability depends on the supplier's production line and certification scope.

Commonly referenced standards include:

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate)

- EN 485 series (European standard for aluminum sheet/plate tolerances and mechanical properties)

- JIS H4000 / JIS H4040 (often used for aluminum alloys in Japanese system references)

For tread/checkered patterns specifically, some mills follow internal pattern specifications while keeping base metal requirements aligned with ASTM/EN/JIS chemistry and temper controls. When your project is compliance-driven, it's wise to confirm the mill test certificate shows alloy, temper, and applicable standard.

Alloy Tempering and Processing: Why H14 is Popular

3003 is non-heat-treatable, meaning its strength is not developed by solution heat treatment like 6061. Instead, strength comes mainly from:

- Alloying (manganese)

- Work hardening (strain hardening) indicated by the "H" temper

H14 is achieved through controlled rolling and partial annealing practices that land the material in a stable, fabrication-friendly condition. For customers, this translates to:

- Better dent resistance than soft temper

- Better formability than harder H18-type tempers

- Reliable performance for cutting, drilling, and general shop fabrication

Chemical Composition: Typical 3003 Alloy Table

The exact chemistry can vary slightly by standard and mill practice. Below is a commonly accepted composition range for AA 3003.

| Element | Typical Specification Range (wt.%) |

|---|---|

| Aluminum (Al) | Remainder |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.20 |

| Iron (Fe) | ≤ 0.70 |

| Silicon (Si) | ≤ 0.60 |

| Zinc (Zn) | ≤ 0.10 |

| Magnesium (Mg) | ≤ 0.05 |

| Chromium (Cr) | ≤ 0.05 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

This chemistry is one reason 3003 is known for corrosion resistance in everyday service. It's not a marine-specialist alloy like 5052, but for many general outdoor and industrial uses it performs reliably with minimal maintenance.

Performance Notes Customers Appreciate

Corrosion resistance

3003 generally resists atmospheric corrosion very well. In wet, salty, or chemical-heavy environments, you may consider 5052, but 3003 remains a strong general-purpose choice, especially when budget and availability matter.

Weldability

3003 is weldable using common aluminum welding processes. Appearance and strength in welded areas depend on filler choice and procedure. For structural-critical weldments, consult welding standards and engineering guidance.

Formability

H14 balances strength and bending capability. If extreme forming is required, softer tempers may be preferred, but H14 is a dependable default for many fabricated components.

Slip resistance and cleaning

The raised pattern improves traction, particularly when shoes and surfaces are slightly wet or dusty. The tradeoff is that the texture can hold debris more than a flat sheet, so routine cleaning practices may be needed in food service or high-sanitation spaces.

Choosing 3003 H14 Checkered Plate with Confidence

A good way to select 3003 H14 checkered aluminum plate is to think in terms of the job it must do daily. If you need a surface that feels secure underfoot, resists corrosion without coatings, and stays easy to fabricate, this alloy-temper combination is a dependable standard across many industries.

When requesting a quote or placing an order, it helps to confirm:

- Alloy and temper: 3003 H14

- Base thickness and whether thickness includes pattern

- Pattern type and direction (if appearance alignment matters)

- Standard compliance: ASTM B209 or EN 485 (as required)

- Tolerances, finish, and protective film needs for transport and installation

For many customers, 3003 H14 checkered aluminum plate isn't a flashy choice-it's better than that. It's the kind of material that quietly performs, keeps people steady, and makes finished projects feel solid and professional from the first step onward.