Aluminum Foil for Packaging A1235 & 8079: Two Alloys, One Packaging Mission-Barrier Confidence with Different "Personalities"

In packaging, aluminum foil is often described with the same familiar keywords: barrier, protection, formability, hygiene. But if you look at foil the way a packaging engineer does-like a "functional skin" that must breathe with the production line, survive converting, and still lock out oxygen, moisture, aroma, and light-then alloy choice becomes less about tradition and more about performance character.

A1235 and 8079 are two of the most trusted aluminum foil alloys for packaging, yet they behave differently where it matters most: pinhole resistance, softness, conversion stability, and sealing compatibility. Think of A1235 as the efficient, high-purity classic for general packaging laminations, while 8079 brings a tougher, more pinhole-resistant attitude for demanding pharmaceutical and high-barrier structures.

Why A1235 and 8079 Dominate Packaging Foil Applications

A1235: The purity-driven workhorse for smooth converting

A1235 belongs to the "near pure aluminum" family. Its high aluminum content supports excellent corrosion resistance, clean surface performance, and stable ductility-qualities that matter when foil is laminated, printed, or coated at speed. It is widely used in food packaging laminates, household foil, container stock conversion paths, and general-purpose barrier layers.

When packaging requires reliable formability and consistent surface behavior with inks, adhesives, and lacquers, A1235 is an easy alloy to qualify.

8079: Engineered toughness for higher barrier reliability

8079 is also Al-based, but with controlled additions (notably iron and silicon) that subtly change how the foil withstands stress during rolling and converting. In practical packaging terms, this often translates to improved pinhole resistance at thinner gauges and stronger mechanical behavior in high-barrier structures.

This is why 8079 is frequently specified for pharmaceutical blister foil, strip packs, sachets, and other applications where micro-defects can become macro problems.

A Distinctive Technical Viewpoint: Packaging Foil as a "Defect Budget"

Every packaging line has an invisible defect budget. Not the kind you see instantly, but the kind that shows up as pinholes after lamination, crack lines after folding, or seal failures after thermal cycling. Alloy and temper selection decides how that defect budget is spent.

A1235 tends to "spend" its strengths on surface consistency and ductility, making it friendly to printing and laminating operations. 8079 tends to "spend" its strengths on resistance to defect initiation, especially when gauges get thin and barrier reliability is the headline KPI.

So the question becomes: do you need the smoothest converting experience, or the toughest barrier layer at the limit of thinness? Many high-performing packaging structures use either alloy successfully-when temper, thickness, and standards are matched correctly.

Typical Product Parameters for Packaging Foil (A1235 / 8079)

These parameters are commonly used in packaging supply and can be customized by buyer specification, end-use, and converting method.

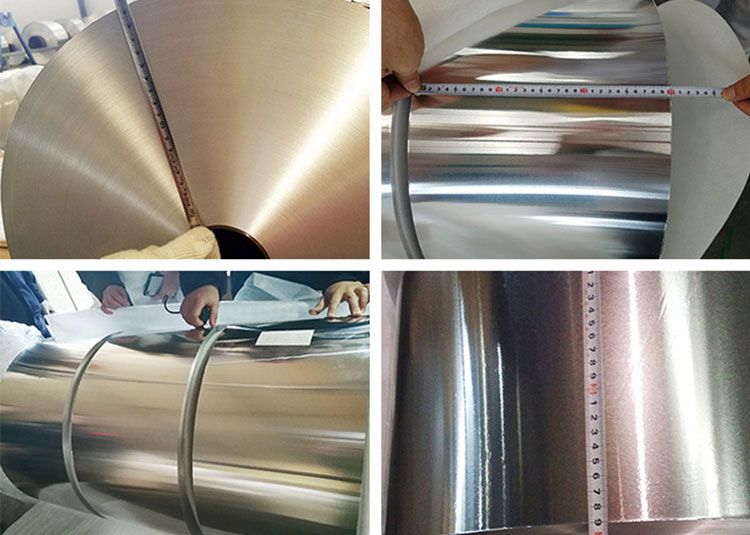

Common thickness range

- Roughly 0.006 mm to 0.200 mm for packaging applications

- High-barrier laminations and pharma often concentrate around thin gauges such as 0.020–0.030 mm, while lidding/container and heavier laminates may use thicker foil

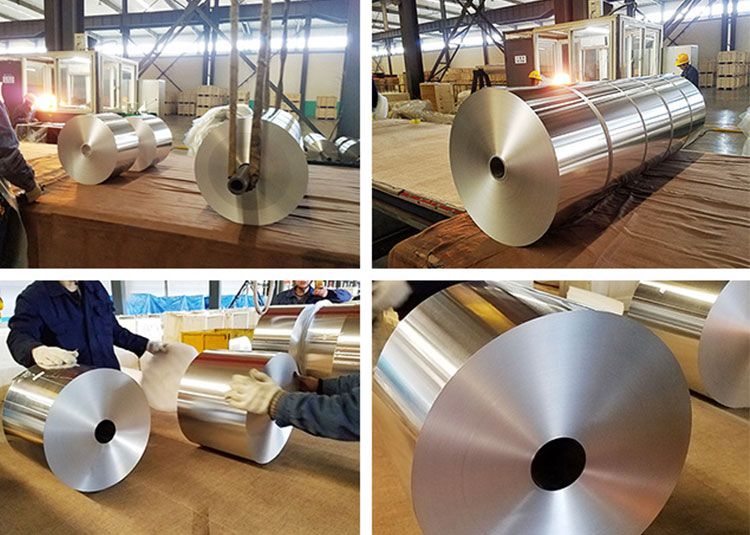

Typical width and coil format

- Width, core ID, coil OD, and coil weight are produced to customer converting line requirements

- Tight flatness and edge condition control are essential for high-speed lamination and printing

Surface and finish conditions

- One-side bright / one-side matte is typical for rolled foil

- Surface cleanliness targets food/pharma compliance; controlled oiling levels support stable winding and downstream adhesion

performance indicators commonly specified

- Pinholes per area (by gauge and test method)

- Tensile strength and elongation (by temper)

- Wetting tension / dyne level (for printing, coating, and lamination)

- Heat seal lacquer compatibility if pre-coated, or bonding strength targets if supplied for lamination

Tempering Conditions: Why "O" and "H18" Feel Like Different Materials

In packaging foil, temper is not a minor note-it is the operating mode of the foil.

O temper (annealed soft foil)

- High ductility and excellent foldability

- Favored for deep forming, twist wrapping, and applications requiring gentle conformability

- Often used in laminations where the foil must flex without crack initiation

H18 temper (full hard)

- Higher tensile strength, stiffer handling

- Common for lidding, blister base/aluminum lidding structures depending on design, and applications needing stronger web stability

- Can improve running behavior on certain high-speed lines, though it is less forgiving in aggressive folding/forming

Many packaging specs also accept intermediate hard tempers, depending on the converting route and the desired balance between stiffness and formability.

Implementation Standards and Quality References Used in Packaging Foil Supply

Packaging foil is typically produced and inspected under internationally recognized standards and customer protocols. Commonly referenced frameworks include:

- ASTM B479 for aluminum and aluminum-alloy foil for flexible barrier, food, and pharmaceutical packaging

- EN 546 series for aluminum and aluminum alloys foil (dimensions, mechanical properties, and related requirements)

- ISO quality management frameworks and purchaser-specific AQL sampling plans

- Food-contact and pharmaceutical compliance requirements are often aligned with applicable regional regulations (such as EU and US frameworks) and customer declarations of conformity, depending on market destination

In real procurement, the controlling documents are often a combination of alloy/temper standard, dimensional tolerance requirements, and end-use performance tests agreed between supplier and converter.

Chemical Composition: A1235 vs 8079 (Typical Limits)

Actual chemistry can vary by standard edition and supplier controls. The table below reflects commonly used composition limits for packaging foil practice, expressed as mass percent.

| Alloy | Al (min) | Si (max) | Fe (max) | Cu (max) | Mn (max) | Mg (max) | Zn (max) | Ti (max) | Others (each / total) |

|---|---|---|---|---|---|---|---|---|---|

| A1235 | 99.35 | 0.65 | 0.65 | 0.05 | 0.05 | 0.05 | 0.10 | 0.03 | 0.03 / 0.10 |

| 8079 | balance | 0.05–0.30 | 0.70–1.30 | 0.30 | 0.10 | 0.10 | 0.10 | 0.08 | 0.05 / 0.15 |

How this chemistry translates into packaging behavior is the important part. Higher controlled Fe/Si in 8079 influences microstructure in a way that often supports better resistance to pinhole formation at thin gauges, while A1235 leans into purity-driven corrosion resistance and converting-friendly ductility.

Packaging Use Cases Where Each Alloy Shines

A1235 packaging foil is often selected for

- Food laminates where printability, adhesive bonding stability, and cost-performance balance are priorities

- General-purpose barrier layers in multi-material structures

- Household foil and common wrapping formats, depending on thickness and temper

8079 packaging foil is often selected for

- Pharmaceutical blister and strip packaging where barrier integrity is critical

- High-barrier sachets and stick packs, especially at thinner gauges

- Packaging designs where pinhole risk is a primary qualification gate

In many modern packaging specifications, both alloys can be approved, with the final choice determined by thickness, temper, and the converter's defect tolerance targets.

Practical Selection Notes: Matching Alloy, Temper, and Structure

A1235 in O temper is a natural fit when foldability and gentle forming dominate the design requirements. 8079 in O temper is frequently chosen when you want soft foil but with a more robust barrier reliability profile at thin gauges. Full-hard options can improve web handling and stiffness, but they must be matched to forming radius, folding intensity, and lamination design to avoid crack-related failures.

Packaging success usually comes from treating the foil as part of a system: adhesive type, curing conditions, printing inks, lacquer chemistry, and sealing layer all interact with the foil's surface condition and temper.