Marine structures demand materials that can survive constant salt spray, cyclic loading, temperature swings, and occasional impact-without sacrificing weldability or maintainability. Aluminium alloy plate 5083 H321 is a proven marine-grade solution designed for high corrosion resistance, reliable strength in welded structures, and long service life in harsh seawater environments.

1) What Is 5083 H321?

5083 is a non-heat-treatable Al-Mg-Mn alloy (5xxx series). Its strength comes primarily from solid-solution strengthening by magnesium and controlled work hardening. The H321 temper indicates the plate is strain-hardened and stabilized, offering a balance of strength, ductility, and improved stability in service compared with some other strain-hardened tempers.

Why H321 matters in marine: stabilization helps control property changes after forming/welding and supports consistent performance in large welded assemblies such as hull sections and superstructures.

2) Features (What Customers Notice in Real Fabrication)

Marine corrosion resistance (saltwater performance)

5083 is widely selected for its excellent resistance to seawater and marine atmospheres, reducing maintenance cycles and coating dependency. In real-world usage, this translates to fewer corrosion-related repairs on hulls, decks, and coastal structures.

Strong, weld-friendly plate for large structures

5083 H321 provides high strength among non-heat-treatable marine alloys, while remaining highly weldable using common processes (MIG/GMAW, TIG/GTAW). It is well-suited for structural weldments where predictable joint behavior matters.

Good toughness and impact performance

Marine structures face slamming loads, vibration, and occasional impact. 5083 plate offers good toughness and ductility, supporting safe design margins.

Formability suited to shipbuilding workflows

The alloy can be cut, formed, and machined effectively with typical shop equipment, supporting efficient fabrication of complex hull and deck geometries.

3) Chemical Composition (Typical Limits)

5083's performance is driven by magnesium content and controlled additions of manganese and chromium. The following table reflects commonly referenced limits (always confirm against the governing standard for your project).

| Element | Typical specified range / max (wt.%) | Role in the alloy |

|---|---|---|

| Mg | 4.0 – 4.9 | Primary strength contributor; improves seawater corrosion resistance |

| Mn | 0.4 – 1.0 | Enhances strength and work-hardening response |

| Cr | 0.05 – 0.25 | Helps control grain structure and improves corrosion behavior |

| Si | ≤ 0.40 | Impurity control; excessive Si can affect toughness |

| Fe | ≤ 0.40 | Impurity control; excessive Fe can reduce ductility |

| Cu | ≤ 0.10 | Limited to protect corrosion resistance |

| Zn | ≤ 0.25 | Controlled to maintain corrosion properties |

| Ti | ≤ 0.15 | Grain refinement in some product routes |

| Others (each) | ≤ 0.05 | Residual limits |

| Others (total) | ≤ 0.15 | Residual limits |

| Al | Balance | Base metal |

4) Mechanical Properties (Plate, Typical Values)

Mechanical properties vary with thickness, product form, and specification. The table below provides typical expectations for 5083 H321 plate used in marine fabrication.

| Property | Typical value (room temperature) | Notes for design/fabrication |

|---|---|---|

| 0.2% Proof strength (Yield) | ~215 MPa | Supports lighter structures vs. lower-strength marine grades |

| Ultimate tensile strength | ~305 MPa | Strong base metal; joint design still governs in weldments |

| Elongation (A50) | ~12% | Good ductility for forming and energy absorption |

| Hardness (Brinell, HBW) | ~80–95 | Useful for machining and wear expectations |

| Density | ~2.66 g/cm³ | Roughly 1/3 of steel-major weight savings |

Welding note: As with most 5xxx alloys, the heat-affected zone (HAZ) can show some local softening relative to the base temper. Good joint design and correct filler selection (commonly ER5356/5183, depending on requirement) help maintain structural integrity.

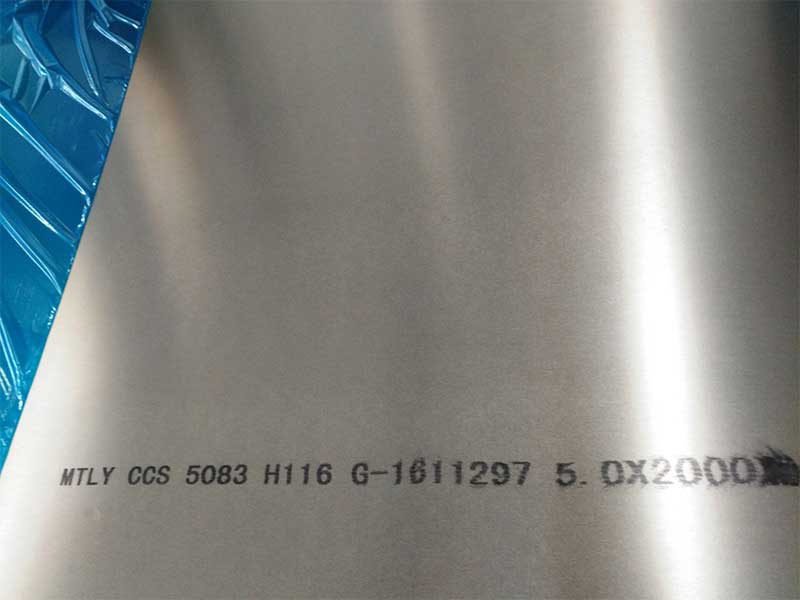

5) Technical Specifications (What to Order)

When customers buy plate for marine projects, clarity in ordering prevents delays and rework. The table below captures typical purchase parameters.

| Item | Common options | Practical guidance |

|---|---|---|

| Product | Aluminium plate 5083 H321 | Specify "marine-grade" plate and intended environment |

| Thickness | ~3 mm to 80+ mm (typical supply ranges vary) | Thicker plate often needs project-specific qualification |

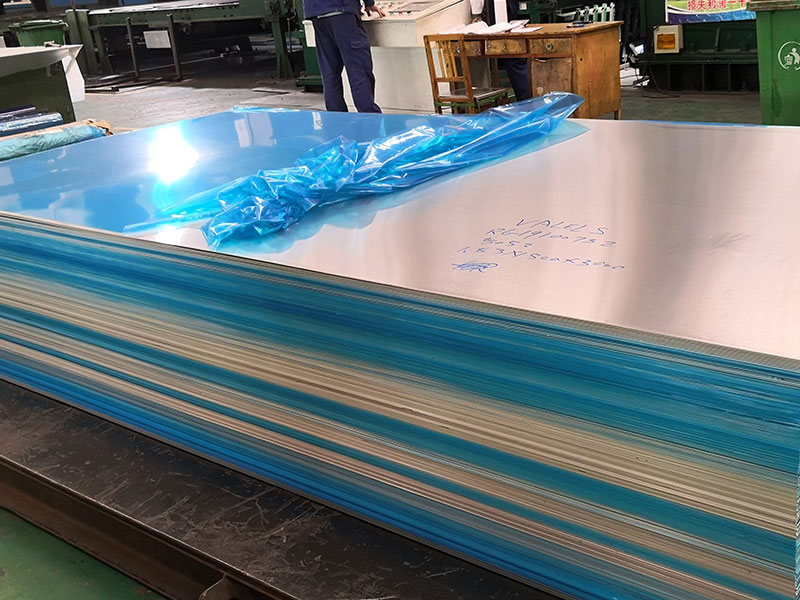

| Width | Commonly up to ~2000–2500 mm | Confirm mill capability and handling limits |

| Length | Commonly up to ~6000–12000 mm | Consider nesting efficiency and transport |

| Surface | Mill finish, one-side PVC, brushed (optional) | PVC film reduces handling scratches for visible panels |

| Standards (typical) | ASTM B209 / EN 485 (project-dependent) | Match to customer class rules/specification |

| Inspection | MTC/EN 10204 3.1 (often) | Add UT or additional NDT requirements if critical |

| Flatness tolerance | Standard / improved | Improved flatness helps panel assembly and reduces fit-up time |

6) Performance Advantages in Marine Use

6.1 Lower lifecycle cost through corrosion resistance

In coastal and offshore exposure, corrosion control often dominates maintenance budgets. 5083's inherent resistance helps:

- Reduce coating complexity (depending on service and aesthetics)

- Extend inspection intervals

- Lower repair frequency in splash zones and wet compartments

6.2 Weight reduction without fragile structures

Switching from steel to 5083 plate can significantly reduce mass, enabling:

- Higher payload or fuel efficiency (vessels)

- Lower center of gravity (stability benefits)

- Easier handling during fabrication and repair

6.3 Excellent weldability for modular shipbuilding

Modern marine fabrication relies on modular sections. 5083 supports:

- High deposition-rate MIG welding

- Good crack resistance when procedures are correct

- Straightforward repair welding and retrofits

6.4 Reliable performance at low temperatures

5xxx series alloys typically maintain good toughness in colder conditions, making 5083 suitable for vessels operating in cooler waters (subject to project qualification).

7) Typical Marine Applications (Where 5083 H321 Excels)

| Application | Why 5083 H321 is chosen | Typical value delivered |

|---|---|---|

| Ship and boat hull plating | High seawater corrosion resistance + strong plate | Long service life, reduced maintenance |

| Decks and superstructures | Strength-to-weight advantage | Improved stability and payload |

| Bulkheads and watertight partitions | Welded structural reliability | Efficient modular fabrication |

| Offshore walkways and platforms | Corrosion resistance + toughness | Safety and durability in spray zones |

| LNG/diesel marine tanks (non-cryogenic) | Weldability and corrosion control | Lower risk of corrosion-related leaks (verify compatibility) |

| Gangways, ladders, marine access systems | Lightweight + robust | Easier installation and handling |

8) Fabrication Notes (To Protect Performance)

| Process | Recommendation | Why it matters |

|---|---|---|

| Cutting | Prefer CNC routing/waterjet/laser (capability dependent) | Controls edge quality and distortion |

| Forming | Use appropriate bend radii; avoid sharp bends | Preserves ductility and reduces cracking risk |

| Welding | Use qualified WPS; common fillers include 5183/5356 | Maintains joint strength and corrosion performance |

| Corrosion control | Avoid galvanic coupling; isolate from carbon steel | Prevents accelerated corrosion at joints |

| Surface prep | Clean before welding (remove oxides/oils) | Improves weld quality and reduces porosity |

5083 H321 is a marine workhorse: high corrosion resistance, strong and weldable plate, and excellent weight efficiency for ships, offshore structures, and coastal infrastructure. It offers an attractive combination of performance and practicality-especially for welded construction where long-term reliability and maintenance cost matter as much as initial strength.