12mm Aluminium Plate: The "Thickness That Behaves" in Real Manufacturing

In metal selection, thickness is often treated like a simple checkbox. Yet 12mm aluminium plate sits in a very particular sweet spot where design intent, shop-floor handling, and real-world service conditions meet. It's thick enough to carry load, resist denting, and machine reliably, while still light enough to keep fabrication efficient and corrosion management straightforward. Seen from a practical engineering perspective, 12mm is not merely "12 millimeters"; it's a behavior profile: stiffness you can count on, thermal response you can predict, and a balance between formability and strength that many projects quietly rely on.

If you're sourcing 12mm aluminium plate for structures, tooling, transportation, marine fabrication, or general industrial frames, the best choice comes from matching alloy family, temper, and compliance standards to what the plate will actually experience: cutting heat, welding cycles, salt exposure, fatigue, or precise machining.

What Makes 12mm Aluminium Plate So Useful?

A 12mm plate thickness often lands in the "stable machining and stable welding" zone. Compared with thinner sheet, it is less prone to distortion during cutting, and it offers more thread engagement and edge distance for bolting. Compared with thicker plate, it usually reduces cost and lead time while improving handling, especially where multiple parts must be nested and cut on CNC routers, lasers, or waterjets.

From a production standpoint, 12mm aluminium plate tends to provide:

- Reliable flatness for fabricated frames and panels

- Good heat dissipation for baseplates and equipment mounts

- Practical stiffness without excessive weight

- Machining depth for pockets, counterbores, and tapped holes

- Better impact resistance than thin sheet in service environments

Typical Parameters for 12mm Aluminium Plate (What Buyers Actually Care About)

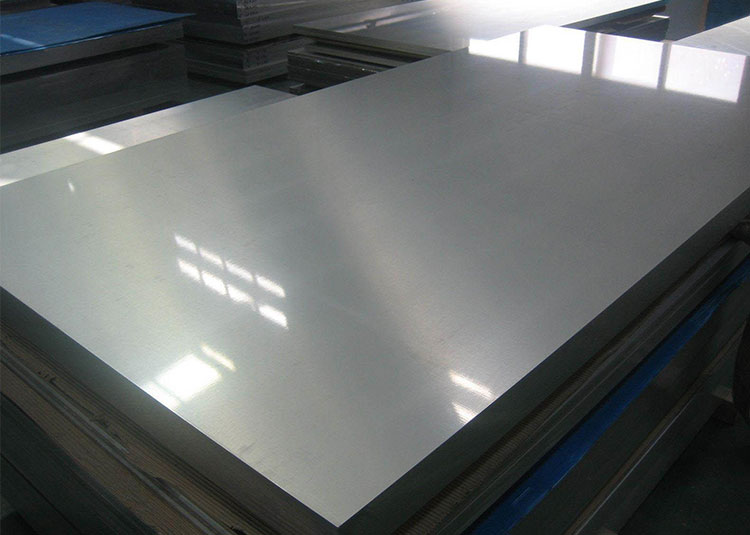

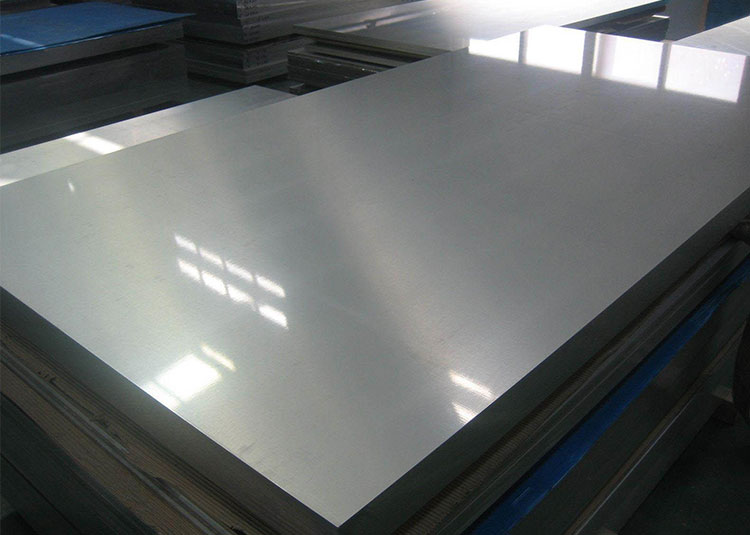

Even before alloy selection, the "quality feel" of a 12mm aluminium plate is defined by dimensional stability and surface condition.

Common commercial parameters include:

- Thickness: 12mm (often produced with tolerance per applicable standard; tighter tolerances may be available by request)

- Width and length: commonly cut-to-size, with standard mill formats depending on region and rolling schedule

- Surface finish: mill finish; optional brushed, anodizing-quality, or protective film for cosmetic and machining needs

- Flatness: depends on alloy, temper, and rolling practice; leveling can be used for improved flatness where required

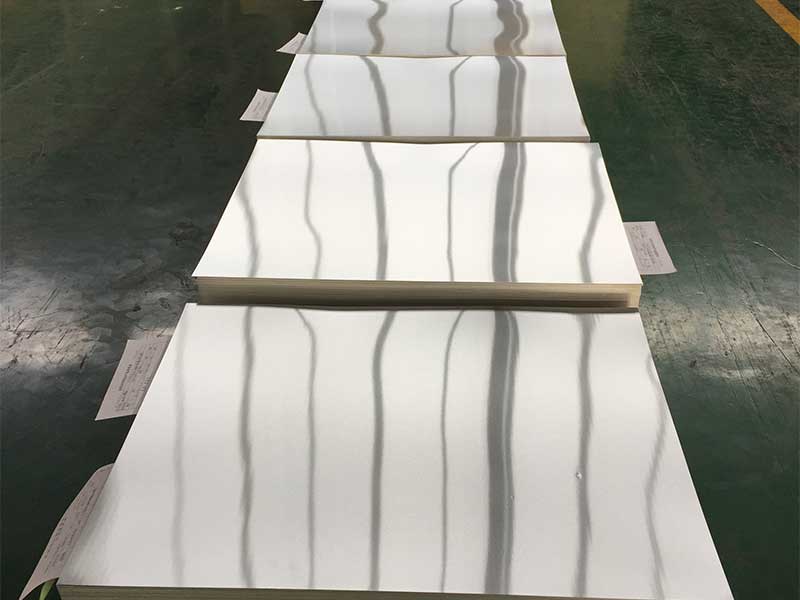

- Protection: paper interleaving or PVC film to reduce handling marks, especially for decorative or precision machining use

Because 12mm plate is frequently CNC-machined, internal stress and plate leveling matter as much as strength. Where precision machining is key, stress-relieved tempers or cast tooling plate options may be preferred, depending on the alloy family.

Implementation Standards: The "Passport" of Your 12mm Plate

A 12mm aluminium plate is often specified by standard because standards define chemical composition limits, mechanical property requirements, tolerances, and inspection rules. Commonly referenced standards in international purchasing include:

- ASTM B209 for aluminium and aluminium-alloy sheet and plate (widely used in North America and international projects)

- EN 485 series for European requirements covering tolerances and mechanical properties of wrought products

- EN 573 series for chemical composition of aluminium and aluminium alloys

- GB/T standards in China for chemical composition, mechanical properties, and dimensional tolerances (often used in Asian supply chains)

Selecting a standard is not paperwork; it's risk control. It determines whether your 12mm plate is evaluated for the properties you actually need, and it prevents "same name, different material" problems in cross-border sourcing.

Alloy Selection for 12mm Aluminium Plate: Choosing by "Work Scenario"

A distinctive way to choose an alloy is to start from the plate's future "day job" rather than its datasheet.

If the 12mm plate is expected to be welded into a structure, 5xxx series alloys are often considered because they maintain good corrosion resistance and weld performance.

If the plate is expected to be machined into load-bearing components where higher strength is needed, 6xxx series can be attractive for balanced strength, machinability, and corrosion resistance.

If maximum strength is prioritized and welding is limited or carefully engineered, 7xxx series may be selected in aerospace-grade contexts, with careful attention to stress corrosion cracking risk and temper choice.

Common alloy families used for 12mm aluminium plate include:

- 5052: strong corrosion resistance, excellent formability, good general-purpose marine/chemical environments

- 5083: notable marine performance and strength retention, commonly used for shipbuilding and heavy structures

- 6061: versatile "engineering alloy," widely used for machined parts and structural components

- 6082: popular in Europe for structural work, good strength and machinability

- 7075: very high strength for specialized applications, usually not chosen for routine welding

Temper Conditions: Why "H" and "T" Matter More at 12mm

At 12mm thickness, temper is often the hidden determinant of performance after fabrication.

Common tempers you will encounter:

- H112 (commonly used for 5xxx plate): a lightly strain-hardened condition with stable, practical properties and good workability

- O (annealed): maximum ductility; suitable where forming is dominant and strength is secondary

- T6 (common for 6061/6082): solution heat-treated and artificially aged; strong and machine-friendly

- T651 (common for 6061): similar to T6 with stress relief by stretching; helpful for machining flatness and reduced distortion

- T73/T74 (often seen in 7xxx): used to improve stress corrosion resistance compared to peak-strength conditions

For machining-heavy projects using 12mm plate, stress-relieved tempers such as 6061-T651 can reduce warping after pocketing or heavy material removal. For welded assemblies, choosing an alloy-temper combination that tolerates weld heat input and post-weld property changes is essential.

Chemical Properties: Typical Composition Table (Common 12mm Plate Alloys)

Chemical composition is not just chemistry; it is the "recipe" controlling corrosion behavior, weld response, and achievable strength. Below is a typical reference table for widely used alloys in plate form. Actual limits depend on the governing standard (ASTM/EN/GB) and the mill's certificate of analysis.

Typical Chemical Composition (wt.%)

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| 5052 | ≤0.25 | ≤0.40 | ≤0.10 | ≤0.10 | 2.2–2.8 | 0.15–0.35 | ≤0.10 | ≤0.10 | Balance |

| 5083 | ≤0.40 | ≤0.40 | ≤0.10 | 0.4–1.0 | 4.0–4.9 | 0.05–0.25 | ≤0.25 | ≤0.15 | Balance |

| 6061 | 0.4–0.8 | ≤0.70 | 0.15–0.40 | ≤0.15 | 0.8–1.2 | 0.04–0.35 | ≤0.25 | ≤0.15 | Balance |

| 6082 | 0.7–1.3 | ≤0.50 | ≤0.10 | 0.4–1.0 | 0.6–1.2 | ≤0.25 | ≤0.20 | ≤0.10 | Balance |

| 7075 | ≤0.40 | ≤0.50 | 1.2–2.0 | ≤0.30 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | ≤0.20 | Balance |

If the application is marine or de-icing salt exposure, Mg-rich 5xxx alloys like 5083 are often chosen for corrosion resilience. If the plate will be anodized for appearance, composition control and surface quality become more critical, especially regarding Fe and Cu which can influence finish uniformity.

Performance Notes That Matter Specifically at 12mm

At 12mm, many fabrication realities become more visible than in thin sheet:

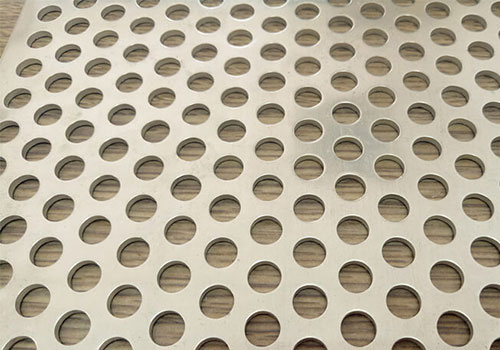

Cutting response and edge quality

Waterjet cutting avoids heat-affected zones and preserves temper properties, while plasma/laser cutting introduces localized heat that can alter edge hardness and potentially affect subsequent forming or anodizing appearance.

Welding behavior and post-weld strength

Heat-treatable alloys such as 6061 in T6/T651 will lose strength in the heat-affected zone unless post-weld heat treatment is used. Non-heat-treatable 5xxx alloys do not "lose temper" in the same way, making them popular for welded structures in corrosive environments.

Machining distortion control

A 12mm plate that will be milled into complex geometries benefits from stress-relieved temper and good flatness. For precision bases, specifying T651 (where applicable) or requesting leveling can reduce rework.

Corrosion logic

Corrosion is rarely about "aluminium vs rust." It's about alloying, environment, and galvanic couples. If a 12mm aluminium plate is fastened to stainless steel in a wet environment, galvanic isolation design may matter as much as alloy choice.

Where 12mm Aluminium Plate Commonly Wins

You'll see 12mm aluminium plate repeatedly in:

- Machine bases, equipment mounting plates, and brackets

- Marine components, dock hardware, and structural panels

- Transportation floors, ramps, and reinforced access panels

- Industrial enclosures and frames requiring a stiff, lightweight wall

- Tooling fixtures and jigs where machinability and stability matter

Its advantage is not "maximum strength" or "maximum formability," but the fact it performs predictably across multiple processes: cut, weld, drill, tap, machine, and finish.

Choosing the Right 12mm Aluminium Plate for Your Project

A useful purchasing mindset is to specify the plate the way the workshop will experience it:

If it will be welded and used outdoors or near salt, consider 5083-H112 or 5052-H112 with the correct standard and certification.

If it will be machined into structural parts with higher strength demand, consider 6061-T6 or 6061-T651, paying attention to flatness and stress relief.

If it must meet a project standard or inspection regime, align alloy, temper, and standard on the purchase order and request mill test certificates showing chemical composition and mechanical properties.

Closing Thought: 12mm is a "Process-Friendly" Thickness

The appeal of a 12mm aluminium plate is that it behaves well in the real world: it's thick enough to be stable, thin enough to be efficient, and versatile enough to fit both structural and machining-driven projects. When you pair the correct alloy and temper with the right implementation standard, 12mm stops being a generic thickness and becomes a dependable manufacturing platform.