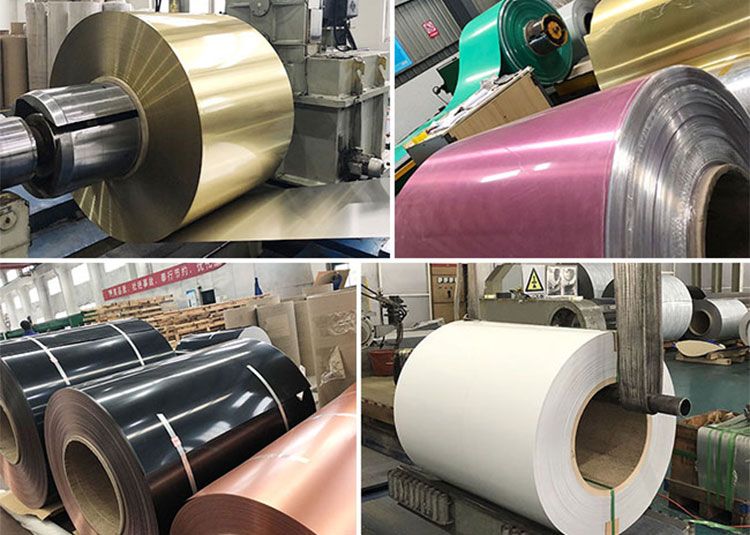

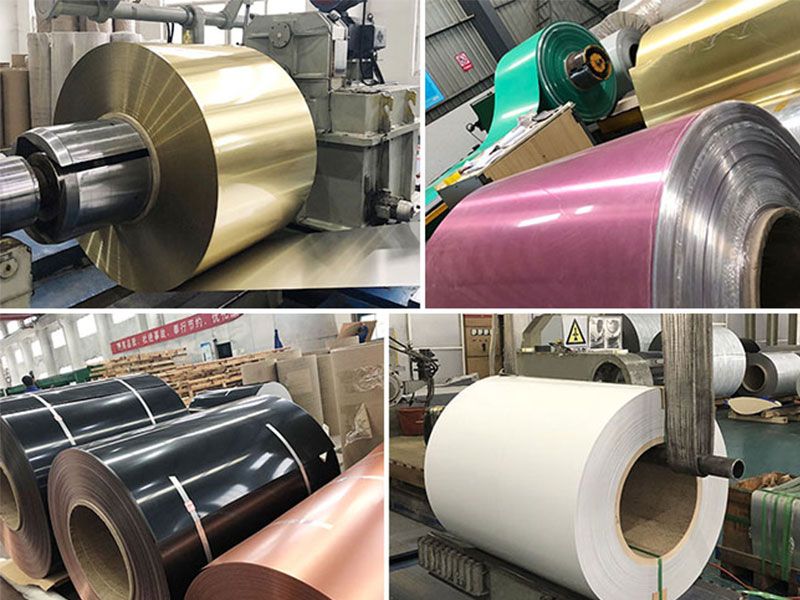

3003 PE PVDF color coated aluminum coil is a pre-finished aluminum product engineered for fast fabrication, consistent appearance, and long-term corrosion resistance. Built on the widely used AA 3003 aluminum alloy core, this coil is coated with either PE (polyester) or PVDF (polyvinylidene fluoride) paint systems to deliver durable color, reliable formability, and a clean surface suitable for architectural and industrial uses.

For buyers, the value is simple: you receive an aluminum coil that is ready to slit, bend, roll-form, stamp, or profile, while maintaining attractive color and stable performance in outdoor or indoor environments.

AA 3003 is a manganese-containing aluminum alloy known for its balanced combination of corrosion resistance, moderate strength, and excellent workability. When paired with PE or PVDF coating systems, it becomes an efficient material solution for:

- Building envelopes and decorative panels

- Rainwater systems such as gutters and downspouts

- Roof and wall cladding

- Signage and display panels

- Appliance and equipment housings

- Interior ceiling systems and trim components

Color coated coil is typically supplied as coil stock, enabling continuous processing and higher throughput for fabricators compared with post-painting.

Features Customers Care About

Reliable formability with stable coating adhesion

AA 3003 is known for bending and forming without cracking. With the correct pretreatment and curing, both PE and PVDF coatings provide strong adhesion so the finish stays intact during profiling, roll-forming, and controlled-radius bending.

Corrosion resistance that fits real-world environments

The aluminum substrate naturally forms a protective oxide layer. Coatings add a second barrier, improving performance in humid climates, urban atmospheres, and general outdoor exposure. For coastal or chemical-heavy environments, PVDF is typically selected for its higher weatherability.

Consistent color and surface uniformity

Coil coating is produced under controlled conditions, resulting in uniform film thickness, consistent gloss, and stable color batch-to-batch-important for large façade areas and high-visibility trims.

Choice of coating system based on service life and budget

PE is cost-effective and widely used for interior or moderate outdoor exposure. PVDF is premium-grade for projects where long-term color retention and chalk resistance are critical.

Alloy Core: AA 3003 Chemical Composition

AA 3003 is an Al–Mn alloy. Manganese improves strength and contributes to good corrosion resistance without sacrificing workability.

| Element | Typical Range (wt.%) |

|---|---|

| Si | ≤ 0.60 |

| Fe | ≤ 0.70 |

| Cu | 0.05–0.20 |

| Mn | 1.00–1.50 |

| Zn | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Al | Balance |

Note: Composition limits may vary slightly depending on the standard and supplier practice.

Coating Options: PE vs PVDF (Quick Selection Guide)

| Item | PE (Polyester) | PVDF (Fluorocarbon) |

|---|---|---|

| Typical use | Interior, trim, moderate outdoor | High-end exterior, harsh weather |

| Weatherability | Good | Excellent |

| Color retention | Good | Outstanding |

| Chalk resistance | Moderate–good | Excellent |

| Cost level | Economical | Premium |

| Common finishes | Gloss / matte / texture | Gloss / matte / metallic |

| Recommended when | Budget-sensitive, shorter design life | Long design life, high UV exposure |

Typical Technical Specifications (Supply Range)

Specifications often vary by application, but the following ranges are common for 3003 color coated coil used in building and general fabrication.

| Parameter | Typical Range / Option |

|---|---|

| Alloy | AA 3003 |

| Temper | H14, H24 (others by request) |

| Thickness (base metal) | 0.20–2.00 mm |

| Width | 20–1600 mm |

| Coil ID | 405 mm / 505 mm (common) |

| Coil OD | Up to ~1600 mm (equipment dependent) |

| Coating system | PE or PVDF |

| Color | RAL / Pantone / custom matching |

| Finish | Gloss, matte, textured, metallic, woodgrain (process dependent) |

| Coating structure | 2-coat 2-bake common; other systems available |

| Protective film | Optional (clear/blue, laser film options) |

| Surface side | Single-side or double-side coated |

Coating Film Thickness (Numerical Reference)

Film build is a decision point because it impacts appearance, durability, and forming performance.

| Layer | Typical PE | Typical PVDF |

|---|---|---|

| Primer | 4–7 μm | 4–7 μm |

| Topcoat | 15–20 μm | 20–25 μm |

| Back coat (service coat) | 5–10 μm | 5–10 μm |

| Total (front side) | ~19–27 μm | ~24–32 μm |

Actual systems depend on manufacturer line capability, project durability targets, and gloss/texture requirements.

Mechanical & Performance Notes (Practical Expectations)

AA 3003 offers a strong balance of strength and ductility, making it a frequent choice for forming-intensive products such as trims, gutters, and profiled sheets. While exact mechanical values depend on temper and thickness, customers typically choose:

- H14 when a slightly harder feel and shape stability are desired

- H24 when added formability is needed without losing too much stiffness

Coating performance is equally important. A properly applied PE or PVDF system supports:

- Good flexibility for roll-forming and bending (within recommended radii)

- Strong adhesion when the pretreatment and primer match the aluminum surface

- Surface durability that reduces maintenance frequency in outdoor use

For any project involving tight bends, deep drawing, or aggressive profiling, it's best to confirm forming limits with the chosen coating type, film thickness, and temper.

Applications: Where 3003 PE PVDF Color Coated Coil Performs Best

Architectural cladding and façade elements

Color coated 3003 coil is widely used for wall cladding, soffit panels, column covers, and decorative casings. PVDF is frequently specified for high-rise exteriors, sun-exposed elevations, and long warranty expectations, while PE is common for sheltered façades and budget-controlled builds.

Roofing, gutters, and rainwater systems

AA 3003's forming behavior suits gutters, downspouts, flashings, ridge caps, and drip edges. Coating adds visual appeal and helps resist staining and weather-related degradation.

Signage, branding panels, and trims

Smoothness and color consistency make this product suitable for sign backgrounds, edging trims, retail décor, and display structures. Matte finishes help reduce glare, while high-gloss finishes enhance visual punch.

Appliance panels and equipment housings

For indoor applications, PE-coated 3003 coil is often used in panel shells, covers, liners, and enclosures where appearance and process speed matter. Coils can be sheared and formed quickly without secondary painting steps.

Interior ceiling systems and decorative sheets

Color coated aluminum is popular for ceiling panels, partitions, and interior trims, especially where humidity resistance is beneficial compared with steel-based materials.

Purchasing Notes: How to Specify Correctly

To ensure you receive coil that runs smoothly on your line, purchasing details typically include:

| Item to Confirm | Why It Matters |

|---|---|

| Alloy + temper | Controls formability and stiffness |

| Base thickness & width | Determines final part strength and processing fit |

| Coating type (PE/PVDF) | Impacts weatherability and design life |

| Front/back coating thickness | Affects durability, flexibility, cost |

| Color + gloss level | Impacts appearance matching and glare control |

| Protective film | Prevents scratches during fabrication and transport |

| Application environment | Helps select PE vs PVDF and coating build |

3003 PE PVDF color coated aluminum coil is a fast-to-process, visually consistent, and corrosion-resistant solution built for modern fabrication. The AA 3003 core provides dependable forming and stable performance, while PE and PVDF coating options allow you to balance cost, durability, and weatherability based on where the product will be used.

For indoor products and moderate exposure, PE-coated 3003 is an efficient choice. For architectural exteriors and long-term color stability under sunlight and harsh weather, PVDF-coated 3003 is the premium standard.