25 mic PVDF color prepainted alloy 3003 H14 aluminum coil is a premium architectural and industrial coil product that combines the corrosion resistance and formability of AA3003-H14 with the long-term weather durability of a PVDF topcoat (25 μm). Designed for roll forming, bending, and light stamping, it delivers reliable color retention, chemical resistance, and a clean, uniform surface finish-making it a preferred choice for exterior cladding, roofing systems, composite panels, and sign industries.

The product is supplied as coated coil with controlled thickness, gloss, and color consistency, supporting efficient fabrication and repeatable performance in demanding outdoor environments.

| Item | Description |

|---|---|

| Base metal | Aluminum alloy 3003 |

| Temper | H14 (strain-hardened, half-hard) |

| Coating system | PVDF (Kynar/Hylar-type chemistry) |

| Topcoat thickness | 25 μm (typical) |

| Common finish structure | PVDF topcoat + primer on front side; service coat or back coat on reverse |

| Typical use environment | Outdoor exposure: UV, humidity, mild-to-moderate industrial atmospheres |

Features (Customer Benefits)

| Feature | What it means in practice |

|---|---|

| Strong outdoor durability | PVDF offers excellent UV resistance, helping maintain color and gloss over years of exposure |

| Corrosion resistance | AA3003 base metal performs well in humid and coastal-adjacent conditions when properly specified and installed |

| Balanced strength and formability | H14 temper supports roll forming and bending while remaining less prone to oil-canning than very soft tempers |

| Stable color and uniform appearance | Coil coating process provides tight control on shade, gloss, and film thickness for large-area consistency |

| Production efficiency | Supplied in coil form for high-speed fabrication lines and reduced on-site painting |

Typical Applications

| Application | Why this product fits |

|---|---|

| Roofing and wall cladding | PVDF topcoat handles sunlight and rain; 3003 forms well into profiles |

| Aluminum composite panel (ACP/ACM) skins | Consistent flatness and coating quality for visual uniformity |

| Fascia, soffit, trims, gutters | Good bendability with durable finish reduces maintenance |

| Signage and display panels | High color stability and clean surface finish for branding work |

| Industrial casing and enclosures | Coating provides chemical and stain resistance in everyday environments |

Alloy 3003 H14: Material Notes

AA3003 is an Al-Mn alloy known for its excellent corrosion resistance and workability. The H14 temper provides a practical strength level for forming operations without excessive cracking risk when proper bend radii are used.

Chemical Composition (AA3003 Typical, wt.%)

| Element | Content (wt.%) |

|---|---|

| Si | ≤ 0.60 |

| Fe | ≤ 0.70 |

| Cu | 0.05–0.20 |

| Mn | 1.00–1.50 |

| Zn | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Al | Balance |

Note: Actual chemistry is per applicable standard and mill test certificate; ranges shown represent common AA3003 limits.

Typical Mechanical Properties (3003-H14)

| Property | Typical value |

|---|---|

| Tensile strength (Rm) | 140–180 MPa |

| Yield strength (Rp0.2) | ≥ 110 MPa (typical range varies by thickness) |

| Elongation (A50) | 4–10% (depends on thickness) |

| Hardness | Approximately 40–55 HB (indicative) |

Mechanical properties depend on gauge, processing route, and applicable specification.

PVDF 25 μm Coating System

PVDF coil coatings are widely specified for exterior architectural products due to their resistance to UV degradation, chalking, and fading. A 25 μm PVDF topcoat is a common premium configuration that balances durability with forming performance.

Typical Coating Layer Structure (Illustrative)

| Side | Layer | Typical thickness |

|---|---|---|

| Front (exposed) | PVDF topcoat | 25 μm |

| Front (exposed) | Primer | 5–8 μm |

| Back (reverse) | Service coat / back coat | 5–12 μm |

Layer design can be customized by project: matte/high-gloss, textured, metallic, mica, or special effect colors.

Coating Performance Characteristics (Typical Targets)

| Performance item | Typical expectation |

|---|---|

| Weathering | Strong color and gloss retention vs. polyester systems in long-term UV exposure |

| Chemical resistance | Good resistance to common pollutants, mild acids/alkalis, and cleaning agents (always confirm with test protocol) |

| Adhesion | Designed for tight adhesion with proper pretreatment and curing |

| Formability | Suitable for roll forming and bending when bend radius and tooling are appropriate |

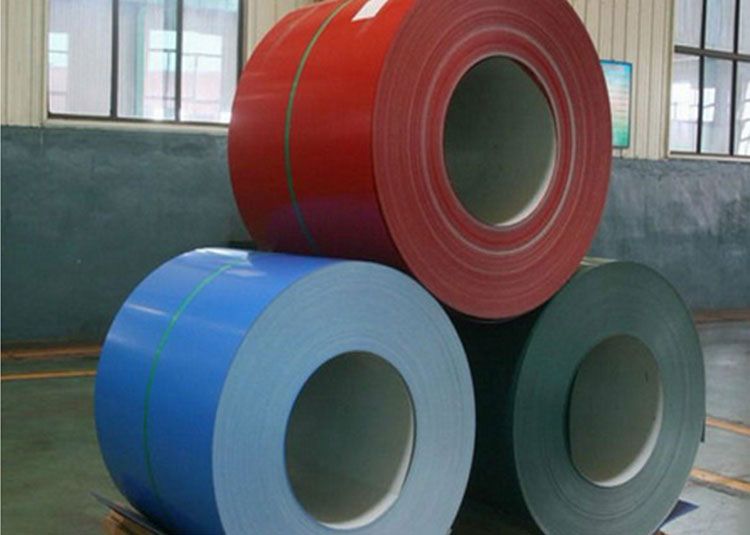

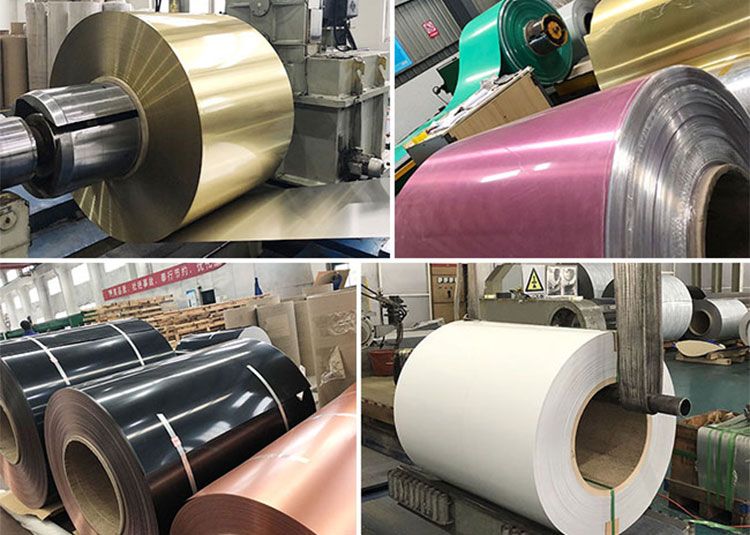

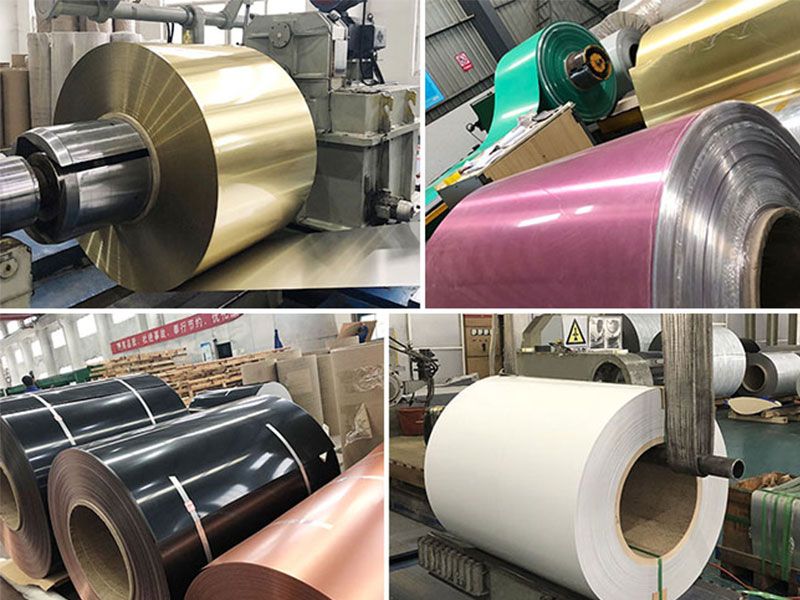

| Surface options | Solid, metallic, pearlescent, wrinkle, matte, high-gloss (availability depends on coating line capability) |

Technical Specifications (Common Supply Range)

| Parameter | Typical range / option |

|---|---|

| Coil thickness (base metal) | 0.30–2.00 mm (common architectural: 0.50–1.20 mm) |

| Coil width | 600–1500 mm (custom slitting available) |

| Coil ID | 508 mm / 610 mm |

| Coil OD | Per weight and line limits |

| Coil weight | Typically 2–5 tons (customizable) |

| Surface finish | Smooth, matte, textured, embossed (optional) |

| Gloss (60°) | Common: 10–80 GU (project-defined) |

| Color | RAL / Pantone / custom matched (subject to batch control) |

| Protective film | Optional PE film for processing protection |

Supply ranges vary by mill capability and order quantity.

Quality Control and Purchase Parameters

When specifying 25 mic PVDF color prepainted 3003 H14 aluminum coil, the most important parameters are measurable and should be written clearly on the purchase order.

| Parameter to specify | Why it matters |

|---|---|

| Coating type and brand grade (PVDF) | Determines weatherability class and service life expectation |

| Topcoat and primer thickness | Controls durability, hiding power, and forming tolerance |

| Color standard and ΔE tolerance | Ensures visual consistency across batches and lots |

| Gloss level and surface texture | Affects appearance and panel-to-panel uniformity |

| T-bend / flexibility requirement | Ensures coating integrity during forming |

| Adhesion and impact resistance | Reduces risk of peeling/chipping during fabrication |

| Pretreatment type | Influences corrosion resistance and coating adhesion |

| Film protection requirement | Helps prevent handling scratches in fabrication lines |

Fabrication and Handling Notes (Practical)

| Topic | Recommendation |

|---|---|

| Bending | Use appropriate inside bend radius; H14 supports forming but avoid overly tight radii for thick gauges |

| Roll forming | Maintain clean rolls and correct tension to prevent scuffing and coil set marks |

| Cutting/slitting | Use sharp tooling to minimize burr and reduce edge paint damage |

| Storage | Keep dry and ventilated; avoid condensation and "wet stack" conditions |

| Cleaning | Use mild detergent and soft cloth; avoid abrasive pads and aggressive solvents unless confirmed compatible |

Why Choose 3003 H14 + 25 μm PVDF

This combination is often selected when customers need a coil that is easy to process, stable in appearance, and built for outdoor life. Compared with general polyester coatings, PVDF is typically chosen for projects where long-term aesthetics and reduced maintenance matter. Compared with softer tempers, H14 offers improved handling robustness and reduced surface waviness in many fabricated profiles.

25 mic PVDF color prepainted alloy 3003 H14 aluminum coil is a high-performance coated aluminum solution for roofing, wall cladding, ACP skins, trims, and signage. Built on corrosion-resistant AA3003-H14 and protected with a 25 μm PVDF topcoat, it provides excellent UV durability, stable color, strong adhesion, and good formability for roll forming and bending. With customizable thickness, width, gloss, and color, this PVDF prepainted aluminum coil delivers long service life and consistent appearance for demanding exterior architectural and industrial applications.