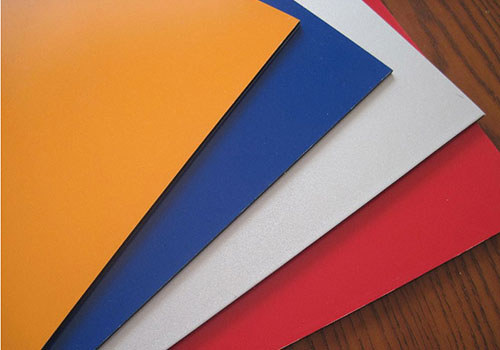

In an ever-evolving landscape of architectural and design innovations, wooden prepainted aluminum coil variations in alloy grades such as 3003 and 3005 offer a versatile and eco-friendly solution to bring elegance and durability to a range of applications. With their stunningly authentic wooden grains and finishes, these pre-painted aluminum coils is know not only for their aesthetic appeal but also for their technical specifications and numerous applications.

Alloy Grades: 3003 vs. 3005

Technical Specifications

Aluminum alloys 3003 and 3005 both belong to the 3000 series and are specifically notable for their exceptional delineability feature while retaining corrosion resistance. Here are the distinguishable parameters of the two alloys relevant to wooden prepainted aluminum coils.

| Parameter | 3003 Alloy | 3005 Alloy |

|---|---|---|

| Chemical Composition | 97.5% - 99.0% Aluminum | 95.7% - 98.1% Aluminum |

| Manganese Content | 1.0% (min) | 1.0 - 1.5% |

| Yield Strength | 130 MPa | 150 MPa |

| Tensile Strength | 185 MPa | 215 MPa |

| Formability | Excellent | Good, though slightly lower |

| Corrosion Resistance | Good | Excellent |

| Temper Variability | H14, H16, H18, H22 | H24, H26 |

Alloy Tempering and Characteristics

- Temper Designations:

- 3003:

- H14: Work-hardened and annealed to half-hard.

- H16: Work-hardened to 3/4-hard.

- H18: Work-hardened to full-hard versions offer varying strength and flexibility, dear to architects wanting to accommodate aesthetic contours.

- 3005:

- H24 and H26: Strikes an ideal balance between strength and flexibility for exterior applications.

The selection of the right alloy temper is essential for projects requiring specific forms, be it automotive, architectural, or home décor reinforcements.

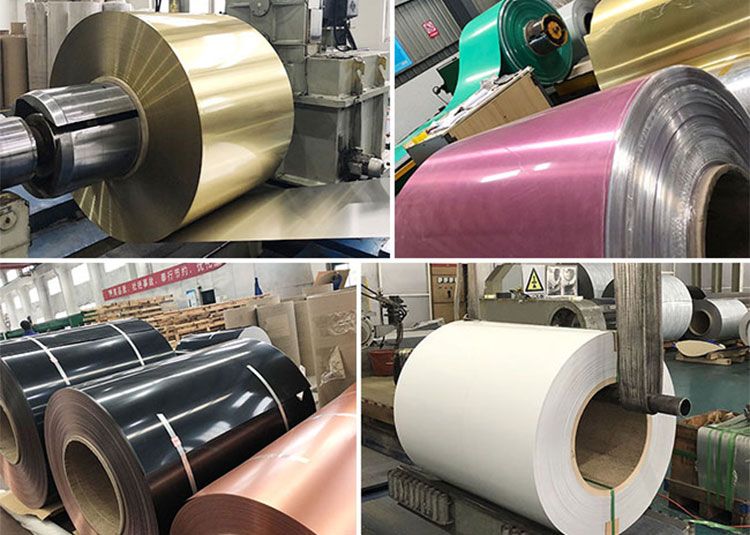

Implementation Standards and Process

The production process for wooden prepainted aluminum coil observes a strict set of standards aimed at preserving performance, aesthetics, and safety. Typically certified to both ISO 9001 and ASTM guidelines, these coils undergo several rounds of FIA (Finished Installations Assessment) primarily ensuring coating durability against weathering and UV stability.

- Coating Process:

- Involves washing and degreasing followed by high-performance primer application and backing coat with wood-like finishes.

- Displaying Edge Performance:

- The finishing should sustain structural challenges imposed by high humidity and varying temperatures. The adhesion aspects of the precoat are optimized through advanced polymer applications, creating unlikely weather-resistant barriers.

Chemical Properties - Resilience at Its Core

8701 Paint maintains its integrity, at the same instance dramatically fostering the vibrantly lifelike appearance of wood grain coatings while preventing common predicaments of fissures and peeling usually found in real wood and unsophisticated substitutes.

| Chemical Property | Value |

|---|---|

| Thermal Conductivity | 205 W/mK |

| OCKL Test (UV Stability) | >1000 hours |

| Recycled Content | 70% |

| Saponifications | Low to None |

| Impact Resistance | IK08 |

Applications and Benefits

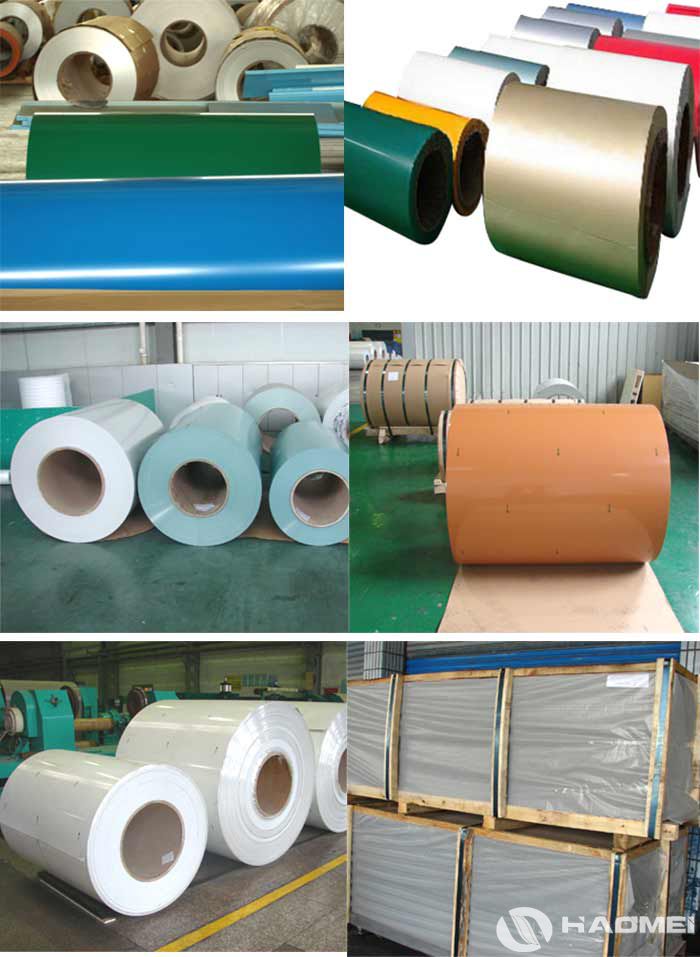

Due to their blend of robustness and deceptive elegance, wooden prepainted aluminum coils have capably locked their position in sectors ranging from:

- Architecture and Facades: Used extensively in residential and commercial buildings, ensuring an appealing outlook without compromising structural integrity.

- Interior Design: Thriving in producing stylish cabinetry, trims, and interior claddings, allowing warmth and sophistication while being low-maintenance.

- Industrial Settings: Automotive, electronic garages, creating attractive/operator-friendly environments.

Transitioning to Sustainable Design Aesthetics

As an amalgamation of modern engineering and natural aesthetics, wooden prepainted aluminum coil compositions teach us about harmonious design in functional applications. They deliver attributes – from lightweight maneuverability to gutted structure preliminaries given to locale differentiation, achieving both quality and eco-resurgence philosophers scenario outlined by resource management capabilities.