1060 H14 H24 Aluminum Sheet is a commercially pure (≥99.6% Al) wrought aluminum alloy in strain-hardened tempers H14 and H24. It offers excellent corrosion resistance, high electrical and thermal conductivity, good formability (especially in H24), and moderate strength (H14 higher than H24). Commonly used in electrical, chemical, architectural, and food-contact applications, 1060 H14 H24 is ideal where purity, conductivity, and corrosion resistance are prioritized over high mechanical strength.

Features

- Chemical purity: Minimum 99.6% Al (low alloying elements).

- Tempers: H14 (strain-hardened, not annealed — higher strength) and H24 (strain-hardened and partially annealed — better formability).

- Excellent corrosion resistance in many environments (atmospheric, mildly corrosive chemicals).

- Very high electrical and thermal conductivity relative to most commercial aluminum alloys.

- Good surface finish and excellent solderability and brazing behavior.

- Non-magnetic and lightweight.

- Suitable for cold forming, drawing (especially H24), spinning and stamping.

- Food-safe and frequently used for cookware and food packaging.

Typical Applications

- Electrical components: bus bars, conductors, connector foils, transformer parts.

- Chemical equipment: tanks, heat exchangers, piping where purity and corrosion resistance are needed.

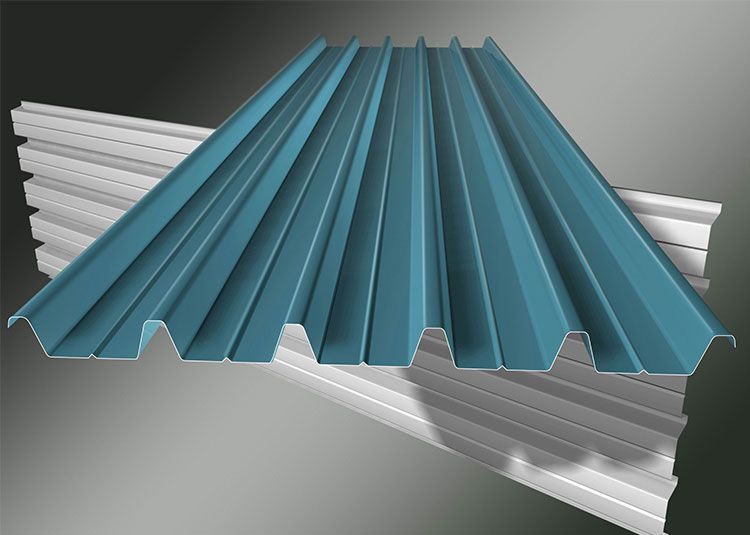

- Architectural and decorative trim: facades, cladding, roof components, signage.

- Food industry: utensils, containers, packaging, food-contact surfaces.

- Reflective surfaces and thermal management: radiators, heat-sinks (where high conductivity is useful and strength demands are moderate).

- Automotive and transportation: trim, panels, fuel tanks (in some designs).

- General fabricated parts requiring good formability and corrosion resistance.

Alloy Overview

- Alloy series: 1xxx (commercially pure aluminum)

- Alloy designation: 1060

- Principal alloying elements: none significant — purity achieved by low amounts of Si, Fe, Cu, Mn, Mg, Zn, Ti, Cr, Ni, V, and other residuals.

Chemical Composition (EN/ASTM typical)

| Element | Typical (wt%) | Range (wt%) per standards |

|---|---|---|

| Al | Balance (≥99.6) | ≥99.6 minimum |

| Si | 0.25 max | ≤0.25 |

| Fe | 0.35 max | ≤0.35 |

| Cu | 0.05 max | ≤0.05 |

| Mn | 0.03 max | ≤0.03 |

| Mg | 0.03 max | ≤0.03 |

| Zn | 0.05 max | ≤0.05 |

| Ti | 0.03 max | ≤0.03 |

| Cr | 0.05 max | ≤0.05 |

| Ni | 0.01 max | ≤0.01 |

| V | 0.05 max | ≤0.05 |

| Others | 0.15 max | each element ≤0.05 (typical) |

Mechanical Properties — Typical by Temper

| Property | Unit | H14 (strain hardened) | H24 (strain hardened & partially annealed) |

|---|---|---|---|

| Tensile strength (Rm) | MPa | 95 – 115 | 70 – 95 |

| Yield strength (Rp0.2) | MPa | 50 – 80 | 30 – 60 |

| Elongation (A50mm) | % | 6 – 12 | 12 – 25 |

| Hardness (Brinell approx.) | HB | 20 – 30 | 15 – 25 |

| Density | g/cm3 | 2.70 | 2.70 |

| Electrical conductivity | % IACS | 61 – 63 | 61 – 63 |

| Thermal conductivity | W/m·K | ~220 | ~220 |

Note: Values are typical and vary with exact processing, thickness and specific supplier controls. H14 has higher strength and lower ductility than H24.

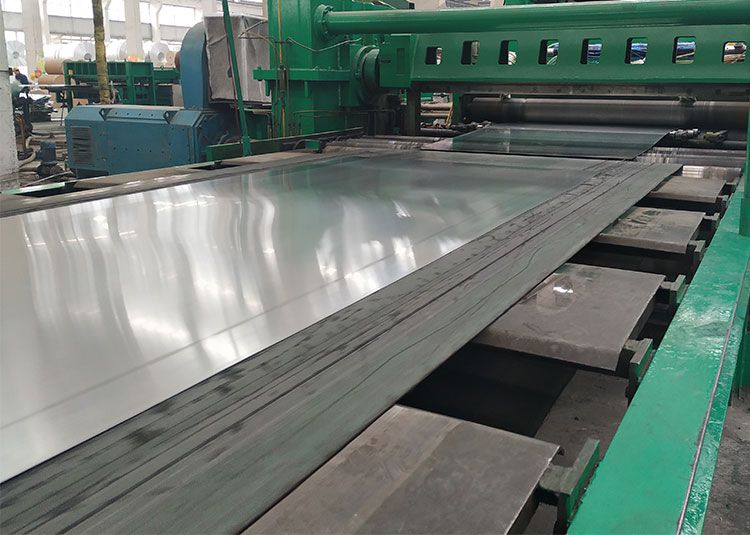

Temper and Processing Details

| Temper | Description | Typical uses & processing notes |

|---|---|---|

| H14 | Strain-hardened (approx. 1/4 hard) | Higher strength, suitable for moderate forming where springback control is needed; less drawability. |

| H24 | Strain-hardened and partially annealed (quarter hard then stabilized) | Improved formability and ductility while retaining some work hardening; good for deep drawing and complex shapes. |

Forming, Welding & Joining

- Cold forming: excellent, more so for H24. Deep drawing and spinning are feasible.

- Hot working: not normally required or recommended for 1060 due to its commercial-purity status; anneal (O temper) if full softening is needed.

- Welding: excellent weldability by MIG, TIG, resistance and spot welding; filler metals typically 1100/4043/4047 (depending on joint and corrosive environment) — choose filler to match desired mechanical and corrosion properties.

- Brazing: good; flux selection and proper joint clearance required.

- Soldering: good general solderability.

Corrosion Resistance

- Excellent in atmospheric, freshwater, and many chemical environments.

- Resistant to pitting and intergranular corrosion in most natural environments.

- In chloride-rich or highly acidic/basic environments, protective measures (coatings, anodizing) may be required for long-term service.

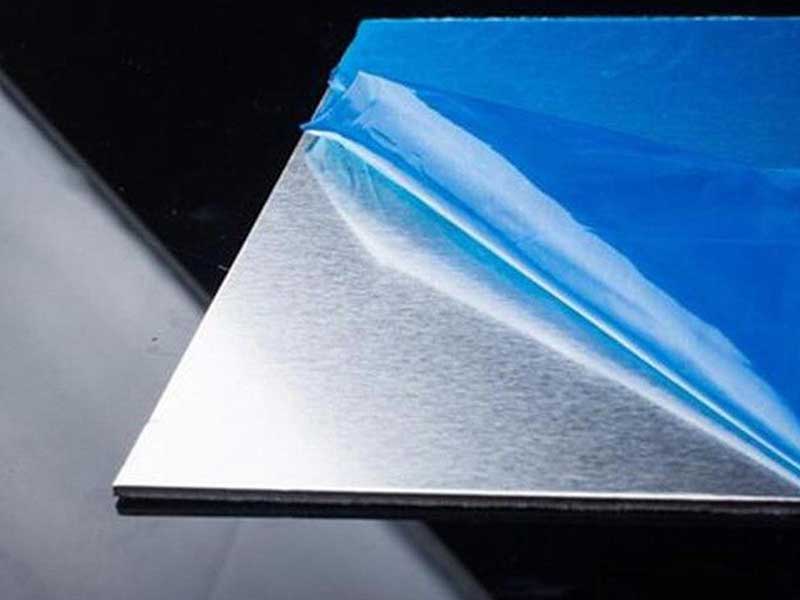

Surface Finishes & Treatments

- As-rolled mill finish (bright or dull) for sheet and coil.

- Anodizing: good response; produces uniform oxide layer with good corrosion and aesthetic properties.

- Painting/coil-coating: excellent adhesion after proper pretreatment.

- Mechanical polishing, chemical etching, and mechanical embossing available.

Typical Dimensions & Supply Forms

| Form | Thickness range (mm) | Width range (mm) | Length / Packaging |

|---|---|---|---|

| Coil | 0.02 – 6.0 (typical) | up to 1550+ | Coils wound and packaged per customer requirements |

| Sheet | 0.2 – 6.0 | up to 2000+ | Cut-to-length, palletized |

| Plate | >6.0 (less common for 1060) | per customer | heavy plate supply possible but limited due to alloy usage |

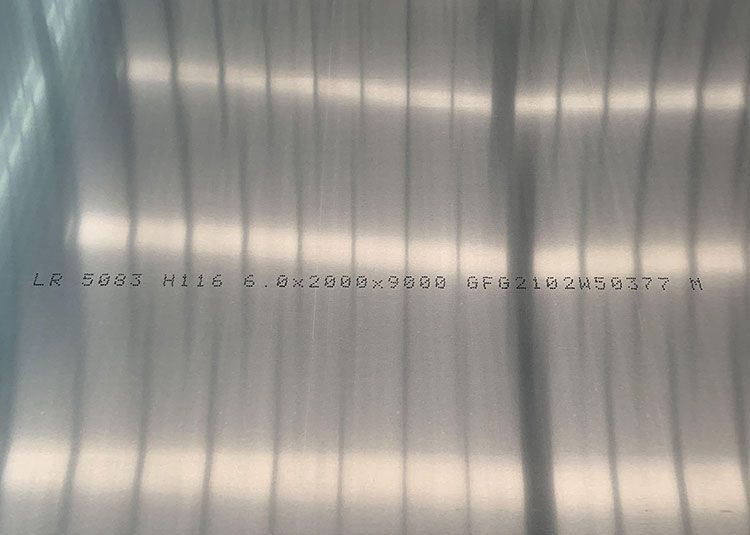

Standards & Specifications

- EN 573 / EN 485 (European standards for chemical and mechanical)

- ASTM B209 (Aluminum and Aluminum-Alloy Sheet and Plate)

- JIS H4000 series (Japanese standards)

- GB/T 3880, GB/T 3190 (Chinese standards)Note: Always confirm supplier certifications and specification sheet for exact compliance.

Quality & Testing

- Typical quality controls: chemical analysis (spectrometry), mechanical testing (tensile, hardness), conductivity tests, surface inspection, dimensional checks.

- Non-destructive tests and traceability per customer and regulatory needs (e.g., mill certificates EN10204 3.1).

Advantages and Limitations

Advantages:

- High purity ensures excellent conductivity and corrosion resistance.

- Good formability (particularly H24).

- Good surface aesthetics and post-treatment compatibility.

- Long-established, widely available alloy.

Limitations:

- Relatively low mechanical strength compared to alloyed series (2xxx, 6xxx).

- Not suitable where high structural load-bearing without reinforcement is needed.

- Softness may require thicker sections for stiffness-sensitive parts.

Selection Guidance

- Choose H14 when higher strength and springback control are required; H24 when better formability and deeper drawability are primary concerns.

- For electrical applications prioritize 1060 for conductivity; for structural components consider stronger alloys.

- Specify surface treatment (anodizing, painting) early for lead-time and finish control.

- Confirm thickness and temper against forming and welding processes to avoid cracking or excessive springback.

Handling & Storage

- Store flat or on suitable racks to prevent warping.

- Protect from prolonged contact with dissimilar metals and corrosive agents.

- Use protective packaging for indoor storage to avoid surface staining.

Ordering Information Template

When requesting quotes, include:

- Alloy and temper: 1060 H14 or 1060 H24

- Form: coil or sheet

- Thickness, width, length

- Surface finish (mill, bright, anodized, painted)

- Quantity and delivery schedule

- Any required standards/certificates (EN, ASTM, mill test report)