Marine aluminum hexagonal bars are precision-formed, six-sided aluminum bars designed specifically for demanding marine environments and heavy fabrication tasks. Their unique cross-sectional geometry provides excellent torque resistance, uniform stress distribution, and convenient clamping surfaces, making them ideal for structural components, fasteners, shafts, fittings, and decorative elements in shipbuilding and marine fabrication.

Features and Benefits

- Uniform geometry with six flat faces for easy wrenching, fastening, and alignment.

- High strength-to-weight ratio suitable for weight-sensitive marine structures.

- Excellent corrosion resistance in marine and coastal atmospheres.

- Good weldability and machinability for complex fabrication.

- Available in typical marine alloys (e.g., 5083, 5086, 6061, 6063) tailored for strength or corrosion performance.

- Long service life with low maintenance compared with steel counterparts.

- Non-magnetic and good electrical conductivity for specialized applications.

Common Marine Alloys Used

Below are the typical alloys used for marine hexagonal bars and their primary advantages:

| Alloy | Typical Use Case | Primary Advantage |

|---|---|---|

| 5083 | Hull fittings, structural members, pressure vessels | Exceptional corrosion resistance in seawater, high fatigue strength |

| 5086 | Keel, hull frames, fasteners | Excellent stress-corrosion cracking resistance |

| 6061 | Shafts, general fabrication, machined parts | Good strength and machinability, heat-treatable |

| 6063 | Architectural trim, low-load fittings | Excellent surface finish, extrusion-friendly |

Chemical Composition (Representative)

Typical chemical compositions for marine-grade aluminum alloys (wt %) are shown below. Values are representative and may vary by standard/specification and temper.

| Element | 5083 (typ) | 5086 (typ) | 6061 (typ) | 6063 (typ) |

|---|---|---|---|---|

| Al | Balance | Balance | Balance | Balance |

| Mg | 4.0–4.9 | 3.5–4.5 | 0.8–1.2 | 0.45–0.9 |

| Si | 0.4 max | 0.4 max | 0.4–0.8 | 0.2–0.6 |

| Fe | 0.4 max | 0.5 max | 0.7 max | 0.35 max |

| Cu | 0.1 max | 0.1 max | 0.15–0.4 | 0.1 max |

| Mn | 0.4–1.0 | 0.4–1.0 | 0.15 max | 0.1–0.5 |

| Cr | 0.05–0.25 | 0.05–0.25 | 0.04–0.35 | 0.05–0.2 |

| Zn | 0.15 max | 0.25 max | 0.25 max | 0.1 max |

| Ti | 0.15 max | 0.15 max | 0.15 max | 0.1 max |

Notes:

- "Balance" indicates the remainder is aluminum.

- Always consult mill certs and applicable marine standards for exact composition and tolerances.

Mechanical Properties (Typical by Alloy and Temper)

Mechanical properties vary with alloy and temper (O = annealed, H = strain-hardened, T6 = solution treated & artificially aged). Values below are typical ranges for commonly used tempers in marine fabrication.

| Property | 5083-O | 5086-H116 | 6061-T6 | 6063-T6 |

|---|---|---|---|---|

| Tensile strength (MPa) | 220–320 | 240–290 | 310–350 | 180–230 |

| Yield strength (MPa) | 100–200 | 145–260 | 240–275 | 130–160 |

| Elongation (%) | 8–18 | 10–18 | 8–12 | 8–12 |

| Hardness (HB) | 40–85 | 50–90 | 95–115 | 50–80 |

| Density (g/cm³) | 2.66 | 2.66 | 2.70 | 2.70 |

Technical Specifications (Hex Bar Geometry & Tolerances)

Standard sizes and tolerances vary by supplier and standard (e.g., ASTM B221 for extruded shapes). Typical dimensional specifications for hexagonal bars used in marine fabrication:

| Parameter | Typical Range / Value |

|---|---|

| Cross-section | Regular hexagon (6 equal sides) |

| Face width (across flats) | 6 mm to 200 mm (custom sizes available) |

| Bar length | 1 m to 6 m standard; custom lengths available |

| Tolerance (across flats) | ±0.1 mm to ±1.0 mm depending on size & standard |

| Straightness | ≤0.5% of length typical for extruded bars |

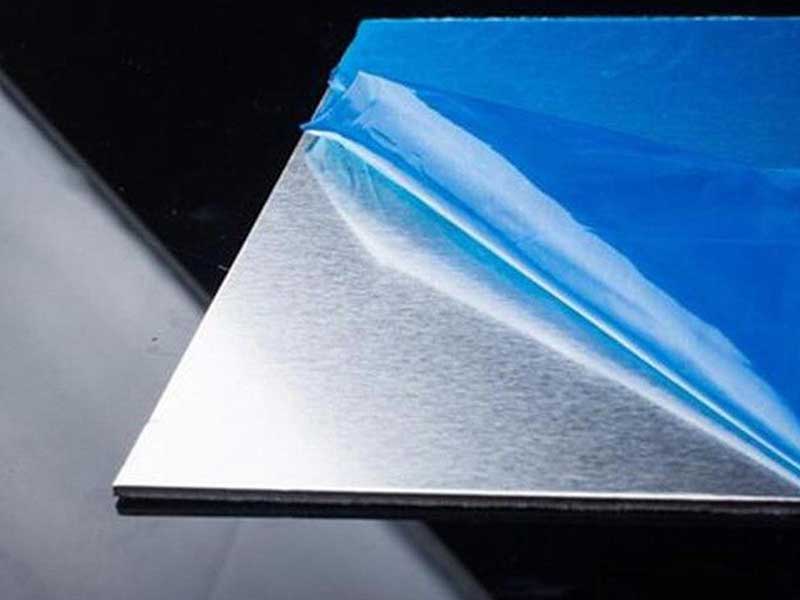

| Surface finish | Mill finish; optional polishing, anodizing, or plating |

| End condition | Saw-cut or milled; chamfers optional |

| Temper | O, H112, H116, T6, etc. depending on alloy |

Always confirm exact tolerances and certifications with the supplier or purchase order.

Corrosion Resistance & Marine Performance

- Marine aluminum alloys (e.g., 5083/5086) exhibit excellent resistance to seawater corrosion and stress-corrosion cracking compared with other aluminum families.

- Protective oxide layer forms naturally; periodic inspection helps detect localized corrosion (pitting, crevice).

- Proper design to avoid dissimilar metal galvanic couples, crevices, and stagnant seawater zones extends service life.

- Anodizing or protective coatings (epoxy primers, polyurethane topcoats) provide additional protection for exposed architectural surfaces.

- Cathodic protection (sacrificial anodes) is commonly used for submerged components.

Welding, Machining, and Fabrication Considerations

Welding:

- 5xxx series (5083, 5086): excellent weldability by MIG/TIG; filler choices (e.g., ER5356) maintain corrosion resistance.

- 6xxx series (6061): weldable, but welded areas may lose some strength; post-weld heat treatment typically not feasible for large assemblies.

Machining:

- Hex bars machine well; 6061 offers superior machinability; 5xxx series machines satisfactorily with appropriate tooling.

- Use coolant to avoid work hardening and burr formation.

Forming:

- 5xxx series are more suitable for cold forming than 6xxx series.

- Avoid sharp bends that may induce cracking in highly strengthened tempers.

Surface Finishing:

- Anodizing (particularly for 6xxx) improves appearance and surface hardness.

- Powder coating or marine-grade paint systems recommended for long-term aesthetic protection.

Typical Marine Applications (Use Cases)

- Structural components: frames, stanchions, deck supports, brackets.

- Fasteners and fittings: nuts, bolts, nuts with hexagonal shafts, coupling nuts.

- Shafts and couplings: drive shafts, splined connectors where hex geometry prevents rotation.

- Deck hardware: cleats, tie-downs, rails, handholds.

- Marine valves and actuators: hexagonal shafts for torque transmission.

- Architectural trim: chamfered hex bars for aesthetic elements on yachts and vessels.

- Offshore platforms: non-ferrous fittings to reduce corrosion and maintenance.

Performance Metrics & Example Selection Table

Below is an example guideline for selecting alloy and temper based on application priority.

| Application Priority | Recommended Alloy/Temper | Performance Metrics |

|---|---|---|

| Maximum corrosion resistance (seawater) | 5083-O / 5086-H116 | High pitting resistance, excellent fatigue & SCC resistance |

| High structural strength | 6061-T6 | High tensile/yield strength, good machinability |

| Best machinability & finish | 6061-T6 / 6063-T6 | Smooth machining, good anodizing surface |

| General-purpose marine fittings | 5086-H32 | Balanced corrosion resistance & formability |

Quality, Certification, and Traceability

- Common standards and certifications: ASTM B221 (extruded bars), ISO 9001, Lloyd's Register, ABS, DNV for marine components.

- Mill test reports (MTRs) should accompany shipments, providing chemical composition, mechanical test results, and heat treatment/temper verification.

- Non-destructive testing (dye-penetrant, ultrasonic) may be specified for critical structural parts.

Handling, Storage, and Maintenance Recommendations

- Store in a dry, ventilated area away from incompatible metals (e.g., steel without isolation) to prevent galvanic corrosion.

- Use protective covers or coatings for long-term outdoor storage.

- Regular inspections on installed parts: check for pitting, crevice corrosion, and fastener loosening.

- Clean with fresh water after saltwater exposure; apply protective coating if needed.

Ordering Guidance

Provide the following information to suppliers to ensure correct product delivery:

- Alloy and temper (e.g., 5083-O, 6061-T6)

- Cross-section size (across flats) and length

- Quantity and tolerance class

- Surface finish and end-condition requirements

- Certification requirements (e.g., MTRs, classification society approval)

- Special processing (anodizing, machining, chamfering)

Marine aluminum hexagonal bars combine corrosion resistance, favorable strength-to-weight, and ease of handling/machining that make them indispensable in modern shipbuilding and marine fabrication. Choosing the right alloy and temper—paired with correct design practices and protective measures—ensures long service life, low maintenance, and reliable structural performance. Whether used for structural members, fasteners, shafts, or decorative elements, marine-grade hex bars offer a versatile and cost-effective solution for marine environments.

For detailed quotations, tolerance sheets, or alloy-specific data sheets (including full mechanical property curves and certified chemical analyses), contact your supplier or our technical sales team with your application requirements and part drawings.