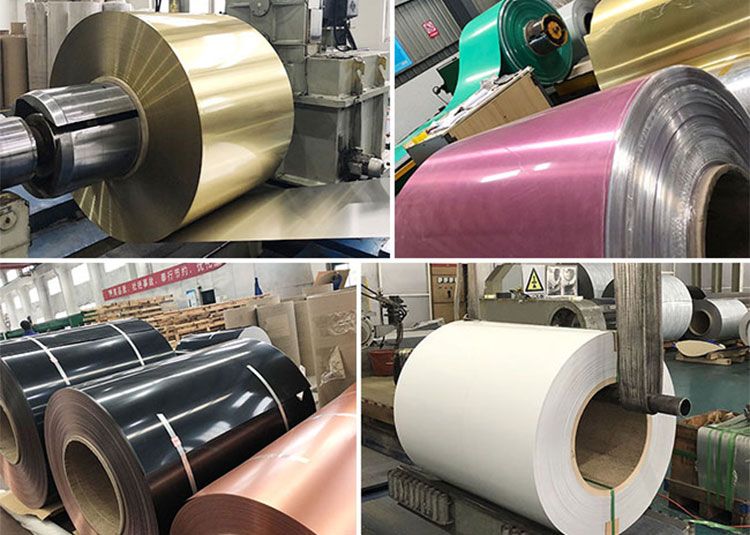

Color coated aluminum sheets have become a cornerstone material in modern building construction due to their effective combination of aesthetic appeal, excellent corrosion resistance, and structural strength.

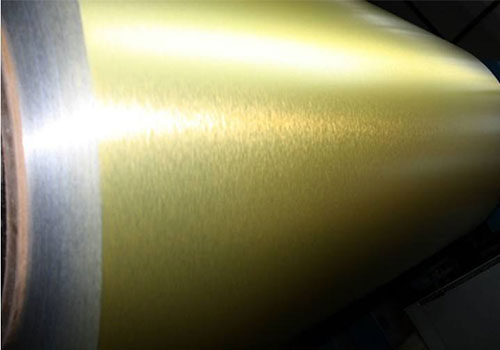

A color coated aluminum sheet is an aluminum substrate pre-coated with a durable layer of organic paint or film, offering enhanced protection and an attractive appearance. This coating system provides superior resistance against harsh environmental conditions-such as UV exposure, moisture, and chemical pollutants-ensuring long-lasting durability.

The essential functions of color coated aluminum sheets for buildings include:

- Corrosion Resistance: The coatings prevent oxidation and degradation caused by exposure to the elements.

- Decorative Finish: Available in versatile colors and textures, facilitating diverse architectural designs.

- Lightweight Strength: Aluminum's natural properties offer high strength-to-weight ratios for efficient construction.

- Thermal Properties: Reflective coatings can reduce heat absorption, contributing to building energy efficiency.

- Ease of Installation: The demand for flat, flexible sheets supports quick and cost-effective handling and assembly.

Typical Applications in Building & Construction

These panels appear throughout both interior and exterior architectural components, including:

- External Cladding and Facades: To enhance structural exteriors with weatherproof, visual design options.

- Roof Panels and Canopies: Providing light yet strong, weather-resistant surfaces.

- Partition Walls and Ceilings: Internal aesthetic upgrades requiring both beauty and longevity.

- Doors and Window Systems: To offer corrosion-resistance and integrate seamlessly with architectural elements.

- Signboards and Sunshading Panels: Lightweight and weather protected sign bases and shade devices.

Their adaptability makes them widely used in commercial buildings, residential apartments, shopping malls, airports, and industrial installations.

Technical Specifications and Standards

Color coated aluminum sheets conform broadly to international industry standards like ASTM, JIS (Japanese Industrial Standards), and EN (European Norms). Adherence to these regulations ensures durability, safety, and performance consistency.

| Property | Specification | Description |

|---|---|---|

| Standard Dimensions | Thickness: 0.2mm - 4.0mm | Width: up to 1600mm, Length customized |

| Coating Thickness | Primer: 5-8 microns | Top Coat: 15-35 microns |

| Surface Finish | Smooth, Embossed, Matt, Glossy | Variety depending on requirement |

| Chemical Composition | See chemical table below | Aluminum alloys commonly 1000, 3000, 5000 series |

| Tensile Strength | 70-280 MPa (depends on temper) | Superior strength due to with temper control |

| Heat Resistance | Up to 200°C | Maintains color stability at normal environmental temperatures |

Alloy Tempering Conditions

The mechanical and physical properties of aluminum sheets heavily depend on their alloy types and tempering state. Here are the typical alloy and temper designations for construction-grade aluminum sheets:

| Alloy Series | Temper | Description | Typical Use Case |

|---|---|---|---|

| 1100 | H14, H24 | Commercially Pure Aluminum | Excellent corrosion resistance, low strength |

| 3003 | H14, H18 | Aluminum-Manganese Alloy | Good corrosion resistance, moderate strength |

| 5052 | H32, H34 | Aluminum-Magnesium Alloy | High strength and corrosion resistance |

| 6061 | T4, T6 | Aluminum-Magnesium-Silicon Alloy | High tensile strength, structural application |

| 3004 | H14, H18 | Alloy of 3003 with added manganese | Suitable for highly painted surfaces and decorative purpose |

Chemical Composition

Quality assurance hinges on stable material chemistry to guarantee the properties of the coated aluminum sheets meet expected standards. Below is a representative chemical composition range for several common alloys used in color coated aluminum sheets:

| Element (%) | 1100 | 3003 | 5052 | 6061 |

|---|---|---|---|---|

| Aluminum (Al) | ≥ 99.0 | ≥ 96.8 | ≥ 97.25 | 97.9 – 99.0 |

| Copper (Cu) | 0.05 max | 0.05 max | 0.10 max | 0.15 – 0.40 |

| Manganese (Mn) | 0.05 max | 1.00 – 1.50 | 0.10 max | 0.15 max |

| Magnesium (Mg) | 0.05 max | 0.05 max | 2.2 – 2.8 | 0.8 – 1.2 |

| Silicon (Si) | 0.4 max | 0.60 max | 0.40 max | 0.4 – 0.8 |

| Iron (Fe) | 0.95 max | 0.7 max | 0.40 max | 0.7 max |

| Zinc (Zn) | 0.10 max | 0.10 max | 0.25 max | 0.25 max |

| Chromium (Cr) | - | - | 0.15 – 0.35 | 0.04 – 0.35 |

Coating System and Color Types

Color coatings used on aluminum sheets often employ high-quality coil-coated paints such as PVDF (Polyvinylidene Fluoride) or FEVE resin-based coatings. The layered coating structure enhances paint adhesion while ensuring weather and abrasion resistance.

| Coating Parameters | Details |

|---|---|

| Primer Layer | Polyurethane-based primers or epoxy primers to promote adhesion |

| Top Coating | Fluoropolymer plexiglass composites such as PVDF (70% resin content minimum) |

| Baking Temperature | Approximately 180°C – 200°C for curing |

| Available Colors | Wide range, including metallic, solid, pearl finishes |

| Gloss Range | Matt (15-30 GU), Satin (30-60 GU), Glossy (60+ GU) GU = Gloss Unit |

Benefits for Building Construction

The choice of color coated aluminum sheets introduces numerous benefits with respect to efficiency, sustainability, and design flexibility.

- Sustainability: Aluminum sheets are 100% recyclable without any loss of physical properties.

- Cost Efficiency: Long lifespan and minimal maintenance reduce overall life-cycle costs.

- Customization: Numerous sizes, profiles, and colors allow perfect fitting architectural visions.

- Fire Resistance: Non-combustible nature ensures higher safety standards.

- Weather Resistance: Ability to endure temperature changes and UV degradation compared to conventional materials.