1. Introduction of Coated Aluminium Sheet Metal

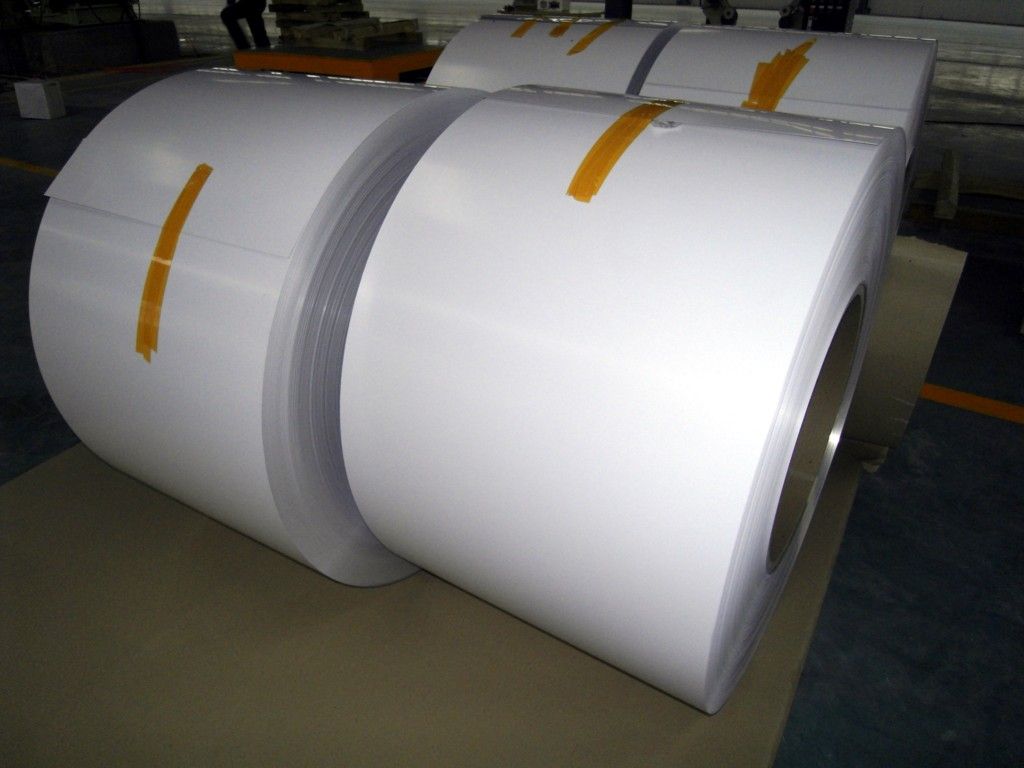

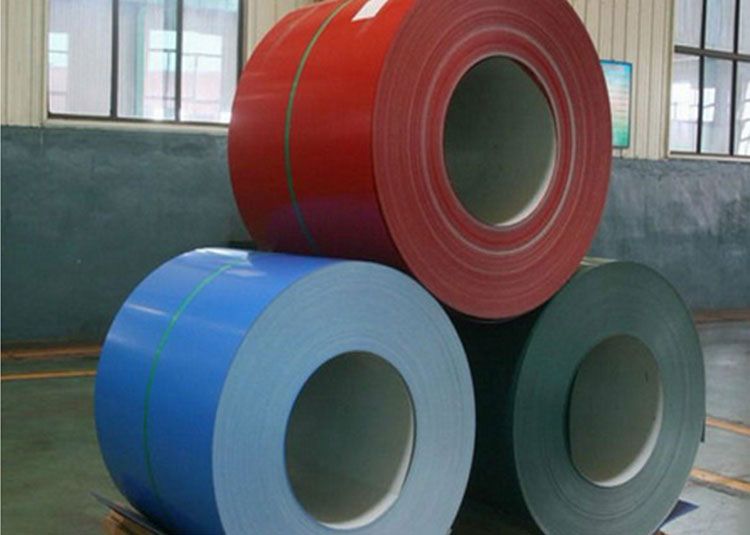

Bare aluminium sheet metal are processed through cleaning, chromizing, rolling coating, baking and other procedures. Then it will have vivid colors on the surface, thus, coated aluminium sheet metal is finished. Color coated aluminium sheet metal is light in weight, has good weld-ability and resistance to correction. Thus, it is vastly used as vacuum sheet, aluminum curtain wall sheet, roofing material, celling and so on and so forth. Haomei Aluminum Industry Co., Ltd. is a manufacturer and supplier of coated aluminium sheet metal for 18 years. The paint that Haomei Al. adopts are international famous, such as American-PPG, Sweden-Beca, Nippon, etc. In this way, the coating properties are pretty stable, comparing to other coated aluminium sheet metal in domestic.

2. Classification of Coated Aluminium Sheet Metal

There are mainly three ways to classify coated aluminium sheet metal at present. According to the manufacturing procedures, coated aluminium sheet metal can be divided into PE coated aluminum sheet and PVDF coated aluminium sheet metal. According to the thickness of paint, coated aluminium sheet metal can be divided into single coating and double coating. The thicknesses of single coating are 5μ, 8μ, 15μ, and 18μ while those of double coating are 25μ-28μ. According to the purpose of final usages, coated aluminium sheet metal is generally divided into roofing material (AL-Mg-Mn roofing system), ceiling materials (aluminum alloy ceiling), drawing metal (drawing on the surface), etc.

3. Features of Coated Aluminium Sheet Metal

Firstly, coated aluminium sheet metal has good resistance to high temperature. The melting point of aluminum is 660℃, common temperatures could not reach its melting point.

Secondly, coated aluminium sheet metal is environment friendly. Coated aluminium sheet metal can be recycled again and again, so little damage can be produced to the environment. This also satisfies the trend all over the world nowadays.

Thirdly, coated aluminium sheet metal has superior resistance to correction to anti oxygen, acid, ultraviolet rays, etc. Therefore, the color and shape can be kept for decade or even more.

Fourthly, the color is pretty uniform with non tolerance. Even for massive ceilings, it can still hold good luster and uniform colors. Least but not last, coated aluminium sheet metal can be cut, bend, drilling, and bear other processing to satisfy diffident demands from customers.

4. Conclusion

Coated aluminium sheet metal has more features than that above, and it has become a part in people’s daily life. Haomei Al. can provide coated aluminium sheet metal with almost all colors available. Advanced rolling and coating production lines guarantee high quality products and vivid colors. However, Haomei Al. only provide coated aluminium sheet metal and coil without drilling holes or bend it. Film and paper can be added to protect products from sea water for long delivery. Fast delivery and good after sale service make Haomei Al. win lots of praise from customers all over the world.