5083 marine aluminum alloy plate is a high-magnesium, non-heat-treatable aluminum alloy engineered for harsh saltwater exposure, heavy-duty structural loads, and long service life. In shipbuilding, it is widely selected for hull plating, decks, bulkheads, superstructures, and offshore modules because it combines strong corrosion resistance with excellent weldability and reliable strength in thick gauges. Compared with many general-purpose aluminum plates, 5083 stands out for its resistance to seawater pitting, good fatigue performance in welded structures, and stable properties across a wide plate thickness range.

For customers who need a marine-grade plate that is easy to fabricate, tolerant to demanding welding schedules, and proven in commercial and military vessels, 5083 delivers a dependable balance of performance and cost.

Why 5083 Is a "Marine" Alloy

5083 belongs to the Al-Mg-Mn family. Its magnesium content drives strength and seawater corrosion resistance, while manganese improves strain hardening behavior and helps maintain toughness. Because it is non-heat-treatable, 5083 achieves strength mainly through work hardening and controlled processing. That makes it especially suitable for welded ship structures, where heat from welding can soften the heat-affected zone; 5083 retains solid performance when properly selected in marine tempers.

Features at a Glance

| Feature | What it means for ships |

|---|---|

| Excellent seawater corrosion resistance | Strong resistance to marine atmospheric corrosion and seawater splash zones |

| High strength among non-heat-treatable alloys | Suitable for hull and structural members where weight reduction matters |

| Very good weldability | Compatible with common marine welding processes; reliable joint integrity |

| Good toughness at low temperature | Suitable for cold climates and refrigerated vessel zones |

| Good formability in appropriate tempers | Enables bending, rolling, and forming for hull panels and complex structures |

| Proven marine pedigree | Used in ferries, patrol boats, fishing vessels, LNG support craft, and offshore platforms |

Typical Shipbuilding Applications

| Area | Typical parts made from 5083 plate |

|---|---|

| Hull structure | Bottom plating, side shell, bilge strakes, longitudinal plating |

| Deck and internal structures | Deck plate, bulkheads, tank boundaries, stiffener webs |

| Superstructure | Lightweight topside panels to reduce center of gravity |

| Offshore and coastal equipment | Helidecks, gangways, walkways, structural modules |

| Small craft and fast vessels | High-speed hull plating and internal framing systems |

Alloy Temper Options for Marine Plates

Common supply conditions for 5083 plate in marine service emphasize a balance of strength, formability, and corrosion performance.

| Temper | Typical use | Notes for customers |

|---|---|---|

| O (Annealed) | Forming-intensive parts | Maximum ductility; lowest strength |

| H111 | General marine plate | Lightly strain-hardened; good all-round choice |

| H116 | Marine hull plating | Enhanced corrosion resistance in marine exposure (commonly specified for seawater service) |

| H321 | Structural hull and deck | Stabilized to reduce susceptibility to property changes and improve consistency in service |

If you are selecting material for continuous seawater exposure, splash zones, or long-life hull plating, H116/H321 are frequently specified because they are tailored for marine corrosion performance and stable mechanical properties.

Chemical Composition (Typical Limits, wt.%)

5083 is controlled tightly to achieve corrosion resistance and stable mechanical behavior. Values below reflect commonly referenced composition limits for 5083.

| Element | Content (wt.%) |

|---|---|

| Magnesium (Mg) | 4.0–4.9 |

| Manganese (Mn) | 0.4–1.0 |

| Chromium (Cr) | 0.05–0.25 |

| Silicon (Si) | ≤ 0.40 |

| Iron (Fe) | ≤ 0.40 |

| Copper (Cu) | ≤ 0.10 |

| Zinc (Zn) | ≤ 0.25 |

| Titanium (Ti) | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Aluminum (Al) | Balance |

Mechanical Properties (Representative Values)

Actual properties depend on thickness, processing route, and testing standard. The following ranges are commonly used for commercial and marine purchasing discussions.

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O | 275–330 | 125–170 | 12–20 |

| H111 | 305–360 | 125–200 | 10–18 |

| H116 | 305–380 | 215–290 | 10–16 |

| H321 | 315–390 | 215–295 | 10–16 |

For ship structures, the practical advantage is straightforward: 5083 provides high usable strength without requiring heat treatment, which simplifies fabrication planning and reduces risk of uneven properties across large welded assemblies.

Physical Properties (Reference)

| Property | Typical value |

|---|---|

| Density | ~2.66 g/cm³ |

| Modulus of Elasticity | ~70 GPa |

| Thermal Conductivity | ~110–130 W/m·K |

| Electrical Conductivity | ~29–32 %IACS |

| Melting Range | ~570–640 °C |

| Coefficient of Thermal Expansion | ~23–24 ×10⁻⁶ /°C (20–100 °C) |

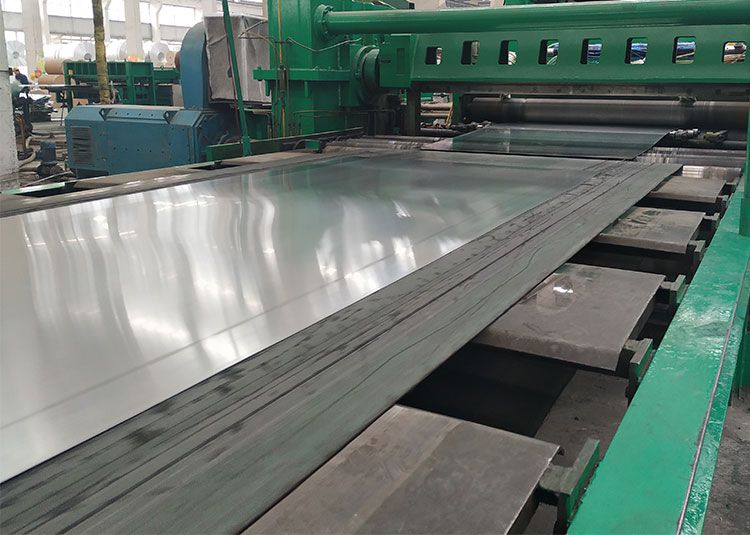

Technical Specifications and Supply Range

Availability varies by mill capability. The table below reflects typical ordering ranges for ship plate programs.

| Item | Typical range / option |

|---|---|

| Product form | Plate |

| Thickness | ~3–150 mm (common marine range) |

| Width | Up to ~2500–3000 mm |

| Length | Up to ~6000–12000 mm |

| Surface | Mill finish, brushed, one-side film (optional) |

| Flatness control | Standard or improved flatness (project-dependent) |

| Certification | Mill test certificate with chemistry and mechanical results; third-party inspection optional |

If your project includes large-area hull panels, request tight flatness and thickness tolerances to reduce fit-up time and welding distortion during assembly.

Corrosion Performance in Marine Environments

5083 is valued because it resists general corrosion in seawater and performs well in marine atmospheres. In real ship service, corrosion success is not only the alloy choice but also the fabrication and protection system.

| Factor | Best practice for long service life |

|---|---|

| Seawater exposure | Use marine tempers (commonly H116/H321) and avoid prolonged contamination with dissimilar metals |

| Galvanic corrosion | Isolate 5083 from copper alloys and carbon steel using coatings, gaskets, and smart joint design |

| Crevice conditions | Minimize water traps; seal lap joints; maintain drainage paths |

| Coating system | Use marine primers and topcoats where required; prepare surfaces properly |

| Welding quality | Control heat input; clean thoroughly to avoid inclusions and porosity |

Fabrication and Welding Notes (Customer-Focused)

5083 plate is widely welded in shipyards because it tolerates production welding and supports strong, durable joints.

| Process | Guidance |

|---|---|

| Cutting | CNC routing, plasma/laser (thin), waterjet, sawing; manage heat to reduce edge distortion |

| Forming | Best in O or H111; larger bend radii recommended for thicker plate |

| Welding | MIG and TIG commonly used; follow qualified procedures for marine structures |

| Filler selection | Match service requirements and WPS; common fillers include 5xxx-series fillers selected by code and joint design |

| Post-weld care | Remove spatter and oxides; consider surface finishing and coating compatibility |

Because 5083 is strain-hardened, localized heating can reduce strength near welds. Ship designs typically account for this using weld details, joint efficiency assumptions, and proper temper selection.

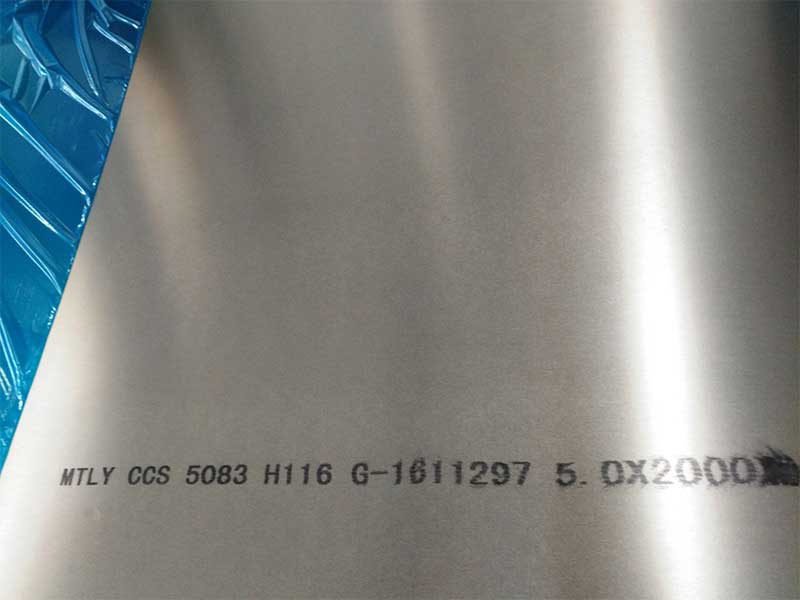

Quality Control Items Customers Should Request

| QC item | What it confirms |

|---|---|

| Chemistry report | Mg/Mn/Cr balance for marine corrosion performance |

| Tensile test results | Strength and ductility by thickness and temper |

| Ultrasonic testing (UT) | Internal soundness for critical hull and pressure-boundary plates |

| Dimensional inspection | Thickness/width/length tolerances and flatness |

| Traceability | Heat number and plate-by-plate identification |

5083 Marine Aluminum Alloy Plate for Ship is a high-strength Al-Mg-Mn marine-grade plate known for excellent seawater corrosion resistance, strong weldability, and reliable structural performance in hull, deck, and offshore applications. Supplied in common marine tempers such as H111, H116, and H321, 5083 plate offers an optimal balance of lightweight strength, formability, and long-term durability in saltwater environments. With controlled chemical composition, stable mechanical properties, and broad thickness availability, 5083 aluminum plate is a proven choice for shipbuilding and coastal structures requiring corrosion-resistant, weld-ready marine aluminum.