Marine environments are less a "place" and more a relentless test chamber. Salt spray, fluctuating temperatures, impact, vibration, crevice moisture, and long service intervals all compete to turn ordinary metals into maintenance liabilities. Marine grade 5083 aluminum alloy sheet has earned its reputation not because it is exotic, but because it is dependable in the exact ways boatbuilders, shipyards, and offshore engineers care about: it resists seawater corrosion, keeps strength after welding, and stays workable during fabrication. Think of it as a material designed for the "middle of the ocean" reality-where repair windows are short and failure is expensive.

What 5083 actually "does" in a marine structure

5083 is an Al-Mg (aluminum–magnesium) alloy with added manganese and trace elements that tune strength and corrosion behavior. Its most practical function is balancing three things that usually fight each other: strength, weldability, and resistance to seawater attack. Many high-strength aluminum alloys gain strength by precipitation hardening, but that route often sacrifices corrosion resistance and weld performance. 5083 takes a different path. It is a non-heat-treatable alloy strengthened mainly by solid-solution effects (magnesium in the aluminum matrix) and by strain hardening from cold work. The result is a sheet that can be welded into hulls, decks, superstructures, tanks, and gangways without "falling apart" in the heat-affected zone the way some stronger alloys might.

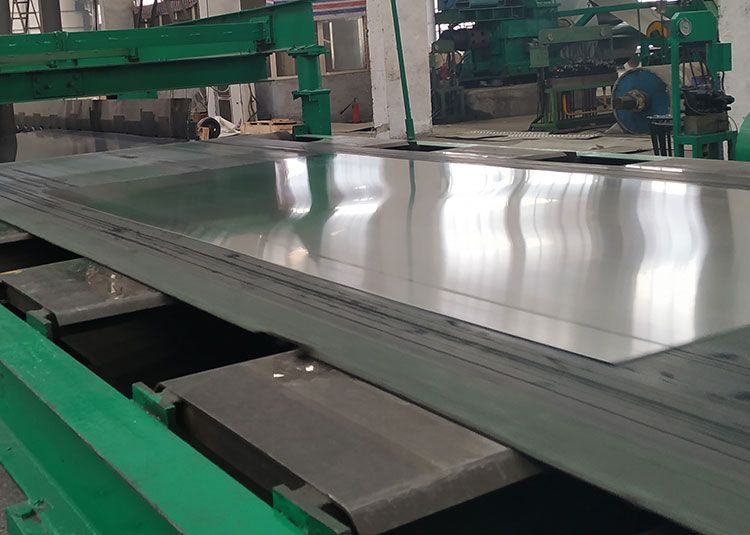

From a design standpoint, 5083 sheet behaves like a reliable structural skin. It is used where large surface area is exposed to saltwater and where weld seams are unavoidable. It tolerates forming operations for curved panels, and it keeps enough ductility to handle real-world knocks that come with docking, wave slamming, and cargo operations.

Marine corrosion is not just "rust." It is a set of electrochemical reactions accelerated by chloride ions, oxygen, and persistent moisture. 5083's magnesium content promotes a stable oxide film that helps protect the base metal in seawater. This is why it is frequently chosen for hull plating and other continuously wetted or splash-zone parts.

A distinctive nuance: corrosion performance depends not only on alloy designation but also on temper and service temperature. High-magnesium aluminum alloys can be susceptible to sensitization (precipitation along grain boundaries) at elevated temperatures, which may reduce resistance to intergranular corrosion. In typical marine service temperatures, 5083 performs strongly; however, fabricators and engineers still pay attention to thermal exposure during processing, coating selection, and long-term operating conditions.

Functions and applications that match real marine workflows

Ship and boat hull plating is the signature use: 5083 sheet provides a strong, corrosion-resistant "envelope" that can be cut, formed, and welded at scale. Fast patrol craft, ferries, workboats, and pleasure boats rely on it where weight savings translate into speed, payload, and fuel efficiency.

Superstructures and decks benefit from 5083 because the alloy reduces top-weight while maintaining stiffness and weld integrity. Lower weight aloft improves stability and motion comfort.

Offshore and port equipment also leverages the alloy's practical durability. Gangways, walkways, ladders, platforms, and enclosures face continuous salt exposure and mechanical wear. 5083 sheet is commonly selected when painted carbon steel would become a coating-maintenance project.

Tanks and containment structures are another strong fit, especially where chloride environments and frequent cleaning are expected. With proper welding procedures and thoughtful design to avoid crevices, 5083 supports long service life.

Cryogenic and low-temperature service is a less obvious but valuable application angle. 5083 is known for good toughness at low temperatures, which helps in certain marine and industrial contexts where cold conditions or refrigerated cargo handling occurs.

Typical parameters customers evaluate when specifying 5083 sheet

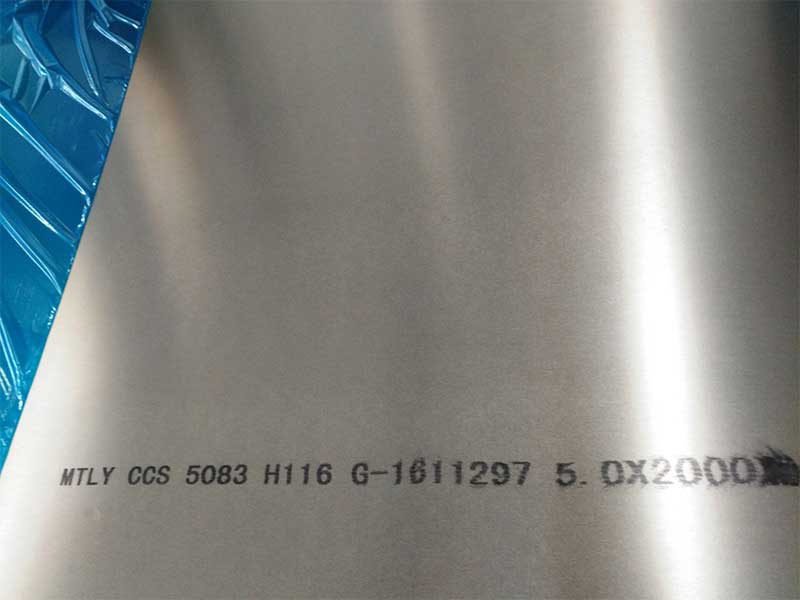

Customers rarely buy "an alloy"; they buy thickness accuracy, flatness, consistent mechanical properties, and dependable certification. Common supply variables include sheet thickness range, width and length tolerances, surface finish, and inspection requirements. 5083 is available in a wide range of thicknesses for marine plating and general fabrication, often from a few millimeters up to several tens of millimeters depending on mill capability and product form.

Mechanical property targets depend strongly on temper. In marine construction, the most commonly referenced temper is 5083-H116 for marine plate/sheet, and 5083-H321 is also widely used. O-temper (annealed) is selected when maximum formability is needed before further processing, while H111 can be used for lightly strain-hardened material.

Below is a concise snapshot of typical mechanical property ranges used for quick reference. Exact values vary by standard, thickness, and product form, so certifications and mill test reports govern final acceptance.

Typical mechanical properties (indicative only; verify per standard and thickness)

| Alloy/Temper | Tensile Strength (Rm) MPa | Yield Strength (Rp0.2) MPa | Elongation (%) |

|---|---|---|---|

| 5083-O | ~275–330 | ~125–160 | ~16–25 |

| 5083-H111 | ~305–360 | ~135–200 | ~14–22 |

| 5083-H116 | ~305–380 | ~215–270 | ~10–16 |

| 5083-H321 | ~305–380 | ~215–270 | ~10–16 |

Implementation standards customers commonly request

For global marine and industrial supply chains, standards function like a shared language between buyer, mill, and fabricator. 5083 aluminum sheet/plate is commonly ordered to one or more of the following, depending on region and project requirements:

ASTM B209 for aluminum and aluminum-alloy sheet and plate (widely used in North America and internationally)

EN 485 series for aluminum wrought products (Europe), with property requirements defined by part and temper

ISO and classification society requirements may apply in shipbuilding projects, where additional inspection, traceability, and approval are necessary

When specifying, buyers typically include alloy, temper, thickness, dimensions, standard designation, inspection level, and any special requirements such as ultrasonic testing, grain control expectations, or enhanced corrosion performance.

Tempering and condition: why it matters beyond "strength"

Temper in 5083 is not just a strength label; it is a manufacturing history. Since 5083 is non-heat-treatable, it gains strength through cold working and stabilization practices. Marine tempers like H116 and H321 are designed to deliver consistent properties and strong resistance in marine environments, particularly with regard to exfoliation and intergranular corrosion behavior.

For fabricators, this translates into predictable forming and welding results. For operators, it translates into fewer surprises over years of service. Selecting a marine-oriented temper is often the simplest way to "buy down risk" in saltwater exposure.

Chemical composition: the alloy's "recipe" that drives performance

5083's corrosion resistance and strength are rooted in its magnesium content, supported by manganese and controlled impurities. The table below reflects typical composition limits used in common specifications; always confirm with the applicable standard and the mill test certificate.

5083 aluminum alloy chemical composition (typical limits, wt.%)

| Element | Content (wt.%) |

|---|---|

| Mg | 4.0–4.9 |

| Mn | 0.4–1.0 |

| Cr | 0.05–0.25 |

| Si | ≤ 0.40 |

| Fe | ≤ 0.40 |

| Cu | ≤ 0.10 |

| Zn | ≤ 0.25 |

| Ti | ≤ 0.15 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

| Al | Balance |

A practical takeaway for fast purchasing decisions

Marine grade 5083 aluminum alloy sheet is best understood as a "weld-first, seawater-first" structural material. It is chosen not merely because it is light, but because it stays reliable after fabrication, resists saltwater corrosion in the real world, and supports efficient shipyard workflows from cutting to forming to welding. When ordering, the most important shortcuts to a correct specification are choosing a marine temper such as H116 or H321, calling out the applicable standard like ASTM B209 or EN 485, and requiring mill certification that confirms both mechanical properties and chemical composition.