Air conditioning heat exchangers work in a demanding environment: constant condensation, frequent wet–dry cycles, airborne salts near coastal areas, cleaning chemicals, and dust that traps moisture. Standard bare aluminum fins deliver excellent heat transfer, but corrosion and formability limits can shorten service life or reduce efficiency over time. Pre coated aluminum fin material with an epoxy layer is engineered to extend durability while maintaining the thermal performance and manufacturability needed for high-volume coil production.

Pre coated aluminum fin material is aluminum strip specifically designed for fin stamping and coil assembly, supplied with a thin epoxy-based protective layer on one or both sides. The coating is optimized to resist corrosion and chemical attack without sacrificing fin forming quality.

outcomes customers typically target with this material include:

- Longer coil life in humid, coastal, or industrial atmospheres

- Reduced white rust and filiform corrosion risk on fin surfaces

- More stable appearance and performance after repeated condensation cycles

- Improved tolerance to cleaning agents and drainage contaminants

Why an Epoxy Layer?

Epoxy coatings are known for strong adhesion and barrier performance. In HVAC fin applications, the epoxy layer acts like a moisture and ion shield, slowing down the electrochemical processes that attack aluminum in the presence of chlorides, sulfates, and acidic pollutants.

The coating system is typically designed to balance:

- Barrier protection against water and salts

- Flexibility for fin pressing, louvers, and collar forming

- Adhesion to withstand expansion, vibration, and thermal cycling

- Thinness to keep heat-transfer penalties minimal

Features at a Glance

| Feature | What it means for customers | Typical value / behavior |

|---|---|---|

| High corrosion resistance | Better durability in coastal/industrial air | Strong salt-spray and humidity-cycle performance (qualification-dependent) |

| Excellent adhesion | Less coating flake during forming | Cross-hatch adhesion commonly meets high grades after bake |

| Formability for fin stamping | Stable louver and collar formation | Designed for high-speed press forming |

| Thin, uniform coating | Maintains efficiency and airflow geometry | Coating generally in the micrometer range |

| Chemical tolerance | Handles mild alkaline cleaners and condensate | Improved resistance versus bare aluminum |

| Coil-friendly surface | Consistent fin-to-tube assembly behavior | Controlled friction and surface energy |

Recommended Alloy and Temper Options

The substrate alloy choice influences fin strength, formability, and baseline corrosion behavior. Epoxy coating then elevates durability to match the application environment.

Typical chemical composition (substrate alloy examples)

| Alloy | Si (%) | Fe (%) | Cu (%) | Mn (%) | Mg (%) | Zn (%) | Ti (%) | Al |

|---|---|---|---|---|---|---|---|---|

| 8011 (common fin stock) | 0.50–0.90 | 0.60–1.00 | ≤0.10 | ≤0.20 | ≤0.05 | ≤0.10 | ≤0.08 | Balance |

| 3003 (higher strength option) | ≤0.60 | ≤0.70 | 0.05–0.20 | 1.00–1.50 | ≤0.05 | ≤0.10 | ≤0.10 | Balance |

| 3102 (heat exchanger focused) | ≤0.40 | ≤0.70 | ≤0.10 | 0.05–0.40 | 0.30–0.90 | ≤0.25 | ≤0.10 | Balance |

Note: Actual limits can vary by standard and supplier practice. Final selection should match fin design, press settings, and corrosion class requirements.

Coating System Concept (Epoxy Layer)

The product generally uses a coil-applied epoxy coating, typically cured in an oven line to create a continuous film with strong adhesion.

| Coating element | Purpose | Common configuration |

|---|---|---|

| Epoxy topcoat | Primary corrosion barrier and chemical resistance | Single-layer epoxy or epoxy-modified system |

| Pretreatment / conversion layer | Promotes adhesion and corrosion resistance | Chromate-free conversion preferred in many markets |

| Optional back-side coating | Balanced protection or assembly behavior | Same or different coating on each side (upon request) |

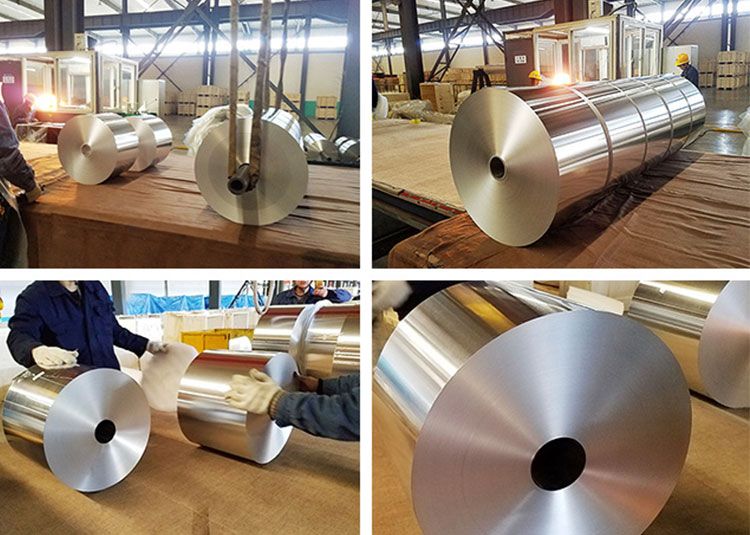

Technical Specifications (Typical Supply Range)

The exact specification depends on fin design, tube expansion method, and corrosion category. The table below reflects common order ranges for epoxy-coated fin stock.

| Parameter | Typical range | Notes |

|---|---|---|

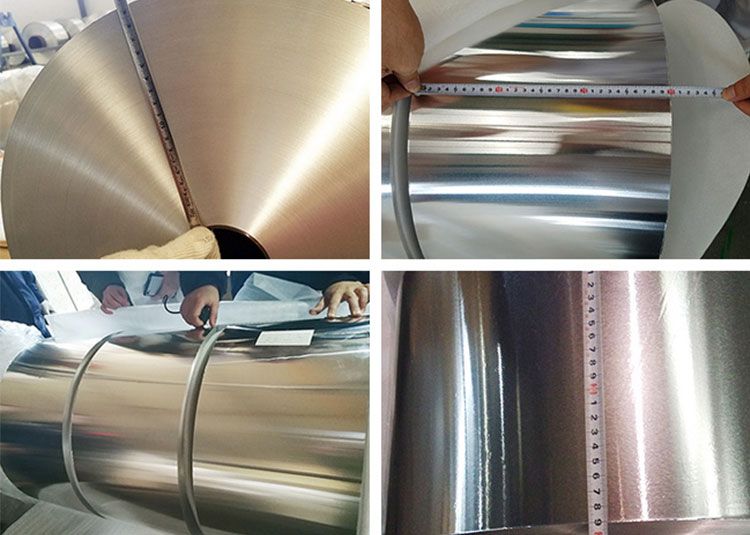

| Thickness | 0.08–0.20 mm | Common HVAC fin gauges fall in this span |

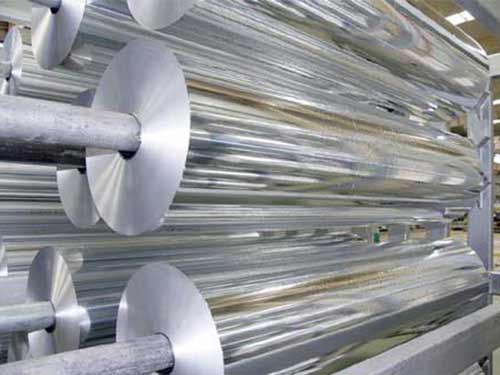

| Width | 200–1300 mm | Slit coils available for fin press lines |

| Temper | H22 / H24 / H26 (or as agreed) | Balances strength and formability |

| Coating thickness (dry film) | 3–10 μm | Thin film supports heat transfer; higher film for harsher environments |

| Coating sides | 1-side or 2-side | 2-side improves all-around protection |

| Surface finish | Smooth / micro-textured | Selected for press performance and coating uniformity |

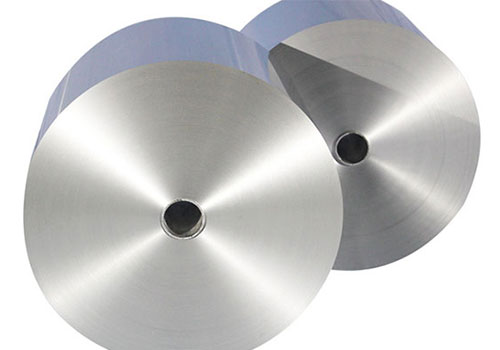

| Coil ID | 150 / 300 / 400 / 500 mm | Based on handling and decoiler |

| Coil OD | Up to logistics limit | Often 1200–1600 mm depending on weight |

| Coil weight | 1–5 t typical | Customized per plant capability |

| Color | Natural/clear to light tint | Often near-transparent; pigments possible by request |

Performance Benefits in Air Conditioning Units

Corrosion resistance where it matters

In operating coils, water is not pure; it carries dissolved ions from air, dust, and cleaning residues. The epoxy layer reduces direct contact between aluminum and corrosive electrolytes, helping mitigate:

- pitting initiation at wet spots

- under-deposit corrosion where dust accumulates

- accelerated attack from chloride-laden coastal air

- edge corrosion risk when combined with good slitting and handling practices

Stable heat exchange over time

A fin surface that stays intact and clean supports consistent airflow and heat transfer. While any coating adds a small thermal resistance, a thin epoxy film is typically chosen to keep efficiency impact low, especially compared with the performance loss that can occur when corrosion products build up and block passages.

Better appearance and reduced after-sales issues

End users notice early discoloration and "white powder" on coils. Epoxy-coated fins can help preserve a cleaner look and reduce corrosion-driven complaints in challenging climates.

Applications

| Application | Environment | Why epoxy-coated fin stock fits |

|---|---|---|

| Residential split AC outdoor units | Rain, condensation, urban pollution | Balanced cost and durability improvement |

| Coastal HVAC units | Salt spray, chloride deposition | Strong barrier protection against chloride attack |

| Commercial rooftops | Sun, wet–dry cycling, dust | Reduced corrosion under deposits and longer coil life |

| Industrial cooling | Acidic/alkaline pollutants, chemical mist (mild to moderate) | Better chemical tolerance than bare fin material |

| Dehumidifiers and dedicated outdoor air systems | High condensation load | Improved resistance to constant moisture exposure |

| Heat pump outdoor coils | Frost/defrost cycling, water runoff | Coating durability supports cycling environments |

Processing and Handling Notes (Customer-Focused)

| Topic | Recommendation | Benefit |

|---|---|---|

| Fin stamping | Use clean tooling, control lubrication | Minimizes coating scuff and ensures crisp louvers |

| Edge handling | Avoid coil edge impacts; use proper guides | Reduces edge damage that can become corrosion sites |

| Storage | Dry indoor storage, wrapped coils | Prevents condensation staining before processing |

| Coil assembly | Verify compatibility with tube expansion and adhesives | Ensures good mechanical fit and long-term adhesion |

| Cleaning | Prefer mild, compatible cleaners; rinse well | Extends coating life and reduces chemical stress |

Quality and Inspection Items Commonly Requested

| Inspection item | What customers learn | Typical method |

|---|---|---|

| Coating thickness | Barrier consistency | Eddy current or microscopic verification |

| Adhesion | Resistance to peeling during forming | Cross-hatch / tape test after cure |

| Gloss / appearance | Visual uniformity | Visual + gloss meter (if specified) |

| Corrosion testing | Suitability for target region | Salt spray / humidity / cyclic tests per agreement |

| Mechanical properties | Press stability | Tensile test, hardness, temper verification |

Selecting the Right Grade for Your Coil

Matching the fin stock to your environment and coil design typically involves:

- substrate alloy choice for strength and formability

- coating thickness level aligned to corrosion severity

- one-side versus two-side coating depending on exposure and cost target

- confirmation testing that reflects real service conditions (humidity cycle, salt exposure, cleaner compatibility)

If you share your fin thickness, louver geometry, press speed, tube material, and target corrosion class, the material can be tailored to provide the best balance of durability, efficiency, and manufacturability.

Pre coated aluminum fin material with an epoxy layer is a practical upgrade for air conditioning units that must survive harsh moisture and contamination conditions. By combining a proven heat-exchanger aluminum substrate with a thin, well-adhered epoxy barrier, it helps coils last longer, look better, and maintain performance with fewer corrosion-related failures-especially in coastal, humid, and polluted environments.