In the realm of modern electronics, the efficiency and reliability of electrical component materials play a pivotal role in advancing technology. Electrolytic capacitors, renowned for their effectiveness in energy storage, owe much of their capability to one specific ingredient: high-purity aluminum foil. This cutting-edge material has transformed our evaluation of energy density, capacitor longevity, and electronic device performance.

What is Electrolytic Capacitor Grade Aluminum Foil?

Electrolytic capacitor grade aluminum foil refers specifically to thin sheets of high-purity aluminum utilized in the manufacture of electrolytic capacitors. This grade of foil typically exhibits a purity of 99.99% or greater. This exceptional purity level is crucial because even trace contaminants (commonly found in lower-purity aluminum) can significantly impact the performance and reliability of capacitors.

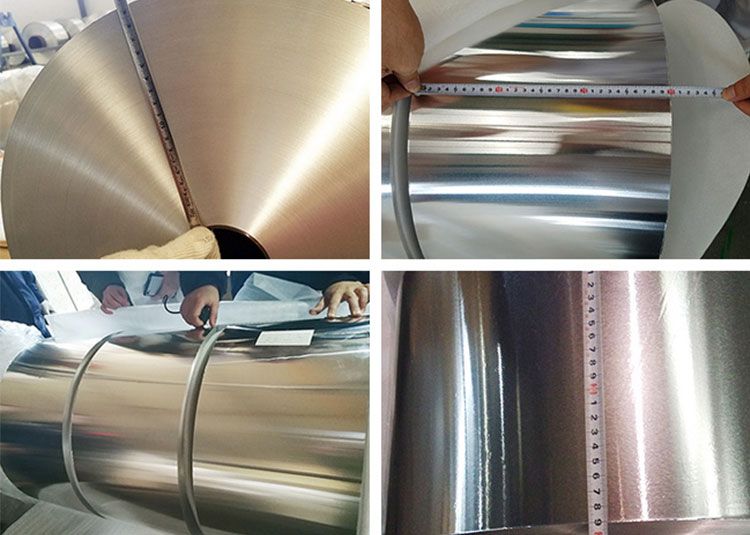

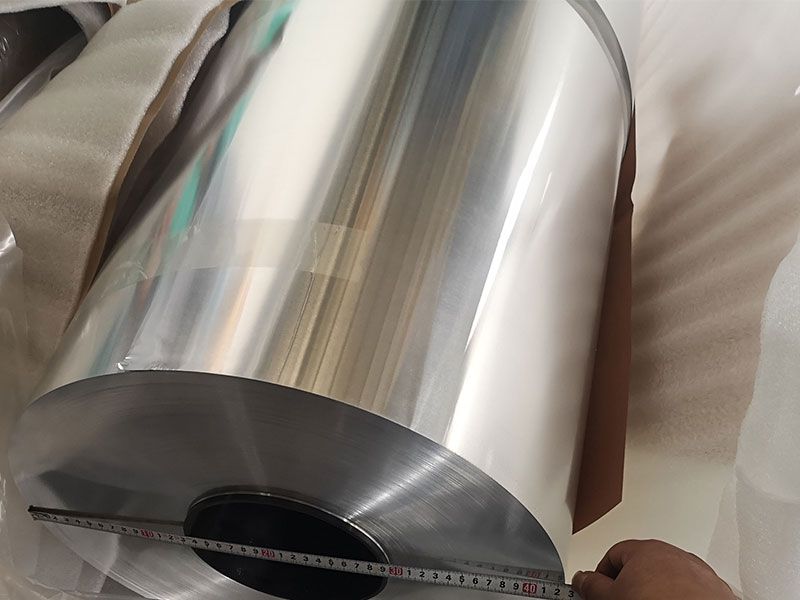

Parameters of High-Purity Aluminum Foil

When assessing aluminum foil meant for electrical applications such as capacitors, various crucial parameters emerge:

| Property | Standard/Value |

|---|---|

| Chemical Purity | ≥ 99.99% Al |

| Thickness | 6 μm to 35 μm |

| Mechanical Strength | 180-250 MPa |

| Electrical Resistance | 1-5 μΩ·cm |

| Surface Roughness (Ra) | ≤ 0.01 μm |

| Yield Strength | ≥ 150 MPa |

Translating Technical Details into Practical Advantages

High Purity for Enhanced Capacitor Performance:The high purity level means fewer defects in aluminum structure, translating to superior charge storage capabilities. Impurities disrupt electron transfer and ultimately reduce the device's efficiency and longevity. Given the rising demand for energy efficiency, using high-purity aluminum ultimately leads to capacitors with longer cycle life and enhanced charge-discharge characteristics.

Mechanical Properties:Mechanical integrity remains of utmost importance. The typical yield strength of electrolytic-grade aluminum foil allows manufacturers to employ it in varying conditions without compromising the efficacy of capacitor function.

Optimal Surface Roughness:Surface roughness highly influences the performance characteristics of laid foil due to the interface with electrolytic solutions. Lower roughness values mean a higher surface area available for electrolytic reactions without yielding to corrosion. The actual chemical dynamics within the electrolyte and foil junction can yield optimally packed layers, maximizing capacitance.

Implementation Standards

Electrolytic capacitor grade aluminum foil maintains certain industry implementation standards. The following standards are integral for manufactures to retain machinery alignments and statutory compliance:

- IEC 60384-4 – specifies standard components and tests associated closely with capacitors for electronic devices.

- MIL-STD-202 – outlines testing requirements for robust component integrity under various environmental conditions.

- ASTM B Standards – define practices for purity and formation of metallic and other high-purity materials used in electronics.

Alloy Tempering and Chemical Properties

High-performance electrolytic capacitor aluminum foil does often undergo specific heat treatments or tempering. For instance, the 1100 and 1350 series of alloys, despite being popular choices due to their high conductivity and workability, afford enhanced light-ly welded tempering opportunities.

- Alloy Tempering Example for Aluminum Foil:

| Alloy Composition | Alloying Elements | Thermal Treatment | Chemical Properties |

|---|---|---|---|

| 1100 | 99.0% Al (min) | Annealed | Weldable, high corrosion resistance |

| 1350 | 99.5% Al (min) | Similar gradings | Optimal balance of conductivity and strength |