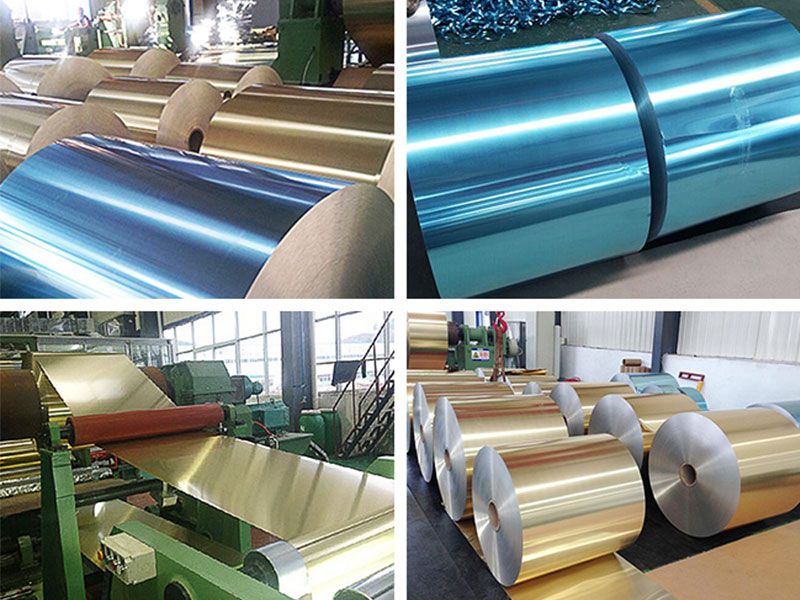

Packaging alloy 8011 aluminum foil is one of the most widely used foil materials for food, pharmaceutical, household, and industrial packaging. It is valued for its dependable barrier performance, stable converting behavior, and broad temper availability ranging from soft, deep-draw capable foils to harder tempers used for lidding and laminate structures. For brand owners and converters, 8011 offers a practical balance of formability, strength, cleanliness, and sealing/laminating compatibility, making it a go-to alloy for high-volume packaging lines.

From everyday kitchen wrap to high-barrier blister packs, 8011 foil protects products against oxygen, moisture, light, odors, and microorganisms. It also supports modern packaging needs such as retort performance, cold-form forming, peelable heat-seal systems, and high-speed printing/laminating, while remaining cost-effective and widely available globally.

Why 8011 Foil Works So Well for Packaging

Reliable barrier at low thickness

Aluminum foil becomes an outstanding barrier even at very small gauges, enabling lightweight packs with excellent shelf-life performance. 8011 is commonly selected where consistent pinhole control and stable rolling quality are required.

Excellent converting behavior

8011 foil performs well in typical packaging processes such as slitting, printing, coating, laminating, embossing, and heat sealing (via lacquer or laminate). Its mechanical balance supports stable tension control on high-speed lines.

Broad temper range for different package designs

Soft tempers support deep drawing and folding without cracking, while harder tempers maintain stiffness for lidding, sachets, and structural layers.

Food-grade and pharma-ready options

When produced under controlled rolling, cleaning, and packaging conditions, 8011 is suitable for direct food contact and pharmaceutical packaging, meeting common regulatory and cleanliness expectations (subject to supplier declarations and compliance testing).

Typical Applications

Packaging alloy 8011 aluminum foil is used across many markets, especially where barrier + processability are critical.

| Application area | Typical product examples | Why 8011 is selected |

|---|---|---|

| Food packaging | household foil, butter wrap, chocolate wrap, cheese wrap | odor/light barrier, good dead-fold, print/coating compatibility |

| Beverage & dairy | yogurt lids, cup lids, dairy closures | stiffness control, consistent sealing lacquer performance |

| Pharma packaging | blister lidding foil, strip pack foil, sachets | barrier protection, cleanliness, high-speed converting stability |

| Flexible laminates | PET/AL/PE, paper/AL/PE, AL/PA/PE | high barrier layer, lamination strength, thermal stability |

| Insulation & industrial | insulation facing, duct wrap, reflective laminates | reflectivity, barrier and durability in laminate structures |

Features Customers Care About

| Feature | What it means in use | Customer benefit |

|---|---|---|

| High barrier protection | blocks moisture, oxygen, and light | longer shelf life, flavor and potency retention |

| Good formability (soft temper) | resists cracking during folding/forming | improved package integrity, fewer leaks |

| Stable strength (semi-hard/hard) | maintains stiffness and flatness | better machinability, cleaner lidding performance |

| Surface quality options | bright/matte sides, low defect rate | improved printing appearance, fewer converting stops |

| Compatibility with lacquers/adhesives | bonds well in laminates | reliable seals and laminate integrity |

8011 is an Al-Fe-Si series alloy, widely adopted in foil rolling due to its stable behavior and mechanical properties across tempers.

| Common temper | Typical packaging use | Notes |

|---|---|---|

| O (soft/annealed) | household foil, wraps, deep-draw and folding applications | best ductility and dead-fold |

| H18 / H19 (hard) | lidding foil, sachets, some laminate structures | higher stiffness, improved handling on high-speed lines |

| H22 / H24 (work hardened, partially annealed) | general packaging and lamination layers | balance of strength and formability |

| H14 / H16 (medium) | specialty laminates, shaped lids | tuned stiffness for specific machines |

Temper selection is typically driven by forming depth, sealing system, laminate structure, and line speed.

Chemical Composition (Typical Limits)

Chemical composition can vary slightly by standard and supplier practice. The table below reflects commonly referenced ranges for 8011.

| Element | Typical content (wt%) |

|---|---|

| Aluminum (Al) | Balance |

| Iron (Fe) | 0.60–1.00 |

| Silicon (Si) | 0.50–0.90 |

| Copper (Cu) | ≤ 0.10 |

| Manganese (Mn) | ≤ 0.20 |

| Magnesium (Mg) | ≤ 0.05 |

| Zinc (Zn) | ≤ 0.10 |

| Titanium (Ti) | ≤ 0.08 |

| Others (each) | ≤ 0.05 |

| Others (total) | ≤ 0.15 |

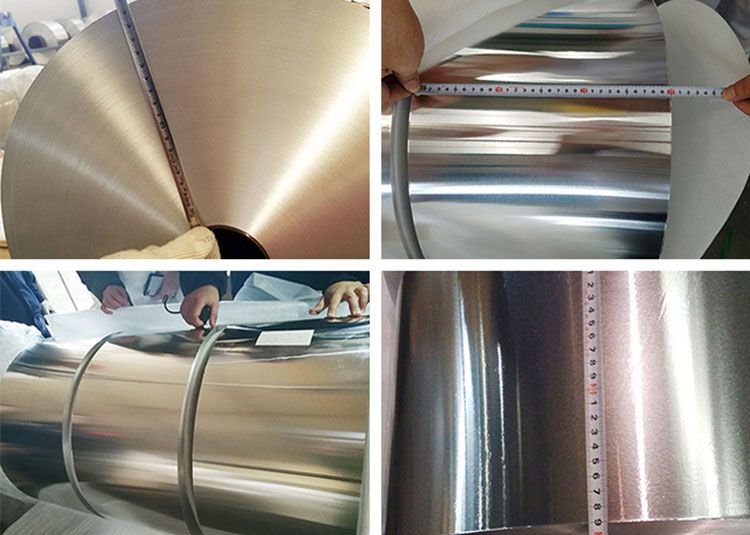

Technical Specifications (Packaging-Oriented)

The following specification ranges are typical for packaging foil supply and can be customized by agreement.

| Parameter | Typical range | Notes |

|---|---|---|

| Thickness | 6–200 µm | thin gauges for lidding/laminates; heavier gauges for trays/industrial uses |

| Width | 100–1600 mm | depends on mill capability and customer converting width |

| Core ID | 76 mm / 152 mm | common for packaging converters |

| Roll OD | up to customer requirement | limited by handling and machine unwinding |

| Surface finish | one side bright / one side matte | natural outcome of foil rolling process |

| Pinhole level | controlled per gauge | thinner foil naturally has higher pinhole sensitivity; process control is key |

| Cleanliness | packaging-grade degreasing | important for coating, printing, and pharma use |

| Joining | optional (as agreed) | splices may be limited for critical pharma lines |

| Packaging | moisture-protected export packing | protects edges and prevents contamination |

Typical Mechanical Property Windows (Guidance)

Mechanical properties depend on thickness, temper, and mill practice. The values below are practical reference windows used in packaging discussions.

| Temper | Tensile strength (MPa) | Elongation (%) | Typical behavior |

|---|---|---|---|

| O | 60–100 | 15–30 | excellent ductility, best folding and forming |

| H22 / H24 | 100–140 | 5–15 | balanced stiffness and formability |

| H18 / H19 | 140–200 | 2–6 | high stiffness, crisp handling, less formability |

For critical applications, specify target ranges and test method (often aligned with ASTM/EN/ISO practices).

Surface, Coating, and Lamination Considerations

Packaging foil rarely works alone; it usually becomes part of a coated or laminated structure. 8011 supports a variety of systems:

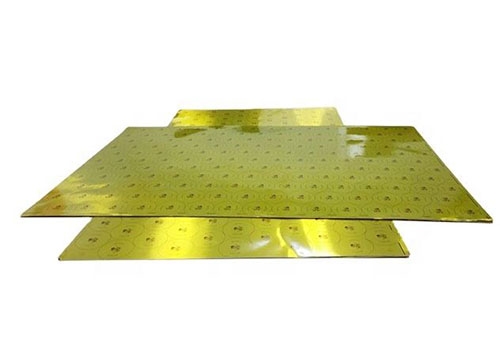

| Converting step | Common options | What to specify |

|---|---|---|

| Printing | solvent-based, water-based, UV (process-dependent) | surface cleanliness, corona/plasma needs for films in laminate |

| Coating | heat-seal lacquer, primer, protective lacquer | coating weight, seal strength target, retort resistance |

| Lamination | adhesive lamination, extrusion lamination | bond strength, aging conditions, delamination criteria |

| Embossing | micro-emboss patterns for aesthetics or grip | depth consistency, appearance standard |

For lidding foils, sealing performance is usually defined by seal strength vs. temperature window, peelability, and hot tack. For pharma blister lidding, additional focus is placed on printing clarity, pinhole control, and compatibility with PVC/PVDC or Alu-Alu systems.

Quality Control Points That Matter in Packaging

| QC item | Why it matters | Typical customer impact |

|---|---|---|

| Gauge tolerance | affects barrier and sealing behavior | stable sealing and forming, fewer rejects |

| Surface cleanliness | impacts coating adhesion and seal | reduced seal failures and coating defects |

| Pinhole/defects | impacts barrier integrity | fewer leaks, better shelf life |

| Flatness and winding | affects high-speed running | reduced web breaks and downtime |

| Edge condition | affects slitting and unwinding | fewer edge tears, improved safety |

How to Choose the Right 8011 Foil Quickly

| If you need… | Typical recommendation |

|---|---|

| deep forming, tight folds, dead-fold wrap | 8011-O with controlled cleanliness and low defect requirements |

| stable lidding at high speed | 8011-H18/H19 with appropriate lacquer system |

| general laminate barrier layer | 8011-H22/H24 with bond strength targets and pinhole spec by thickness |

| pharmaceutical-grade supply | controlled process, documentation, tighter defect limits, agreed testing plan |

Packaging alloy 8011 aluminum foil is a versatile, high-barrier material widely used for food packaging, pharmaceutical blister and strip packs, lidding foil, and flexible laminates. It combines dependable oxygen/moisture/light barrier performance with strong converting compatibility for printing, coating, laminating, embossing, and heat sealing. Available in soft and hard tempers, 8011 foil can be tailored for deep-form wraps, high-speed lidding, and high-barrier laminate structures, with customizable thickness, width, and quality controls such as pinhole limits, cleanliness, and winding standards.