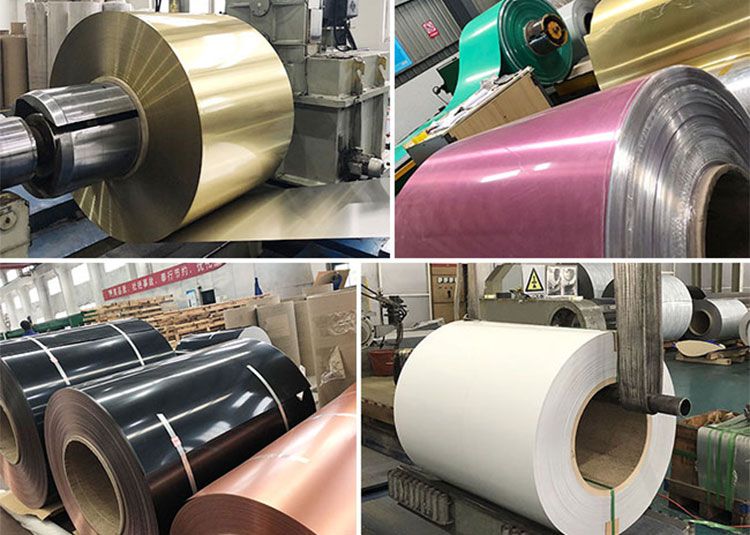

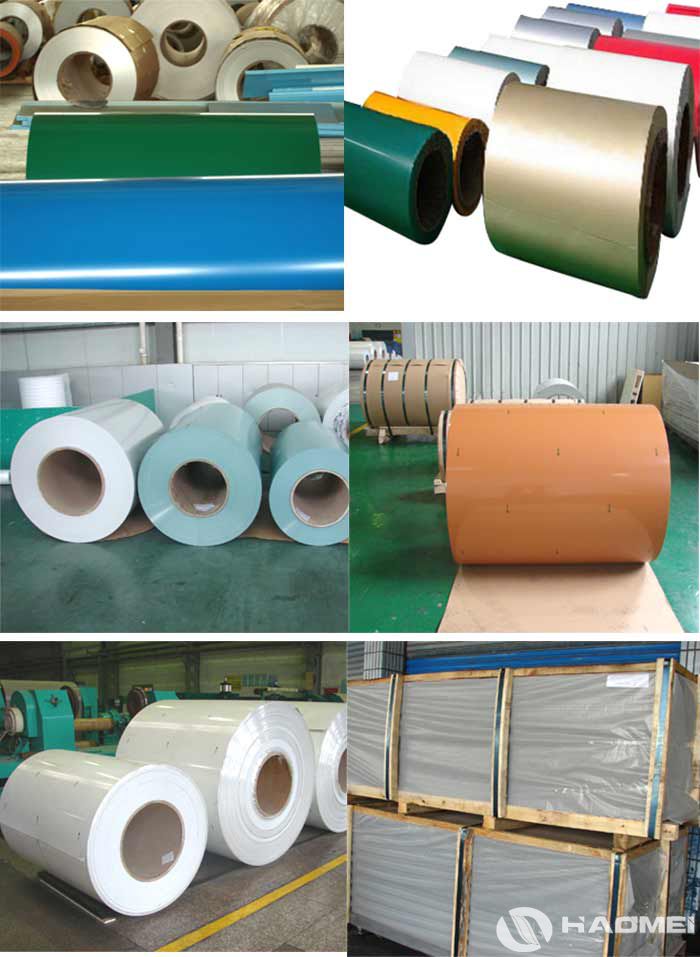

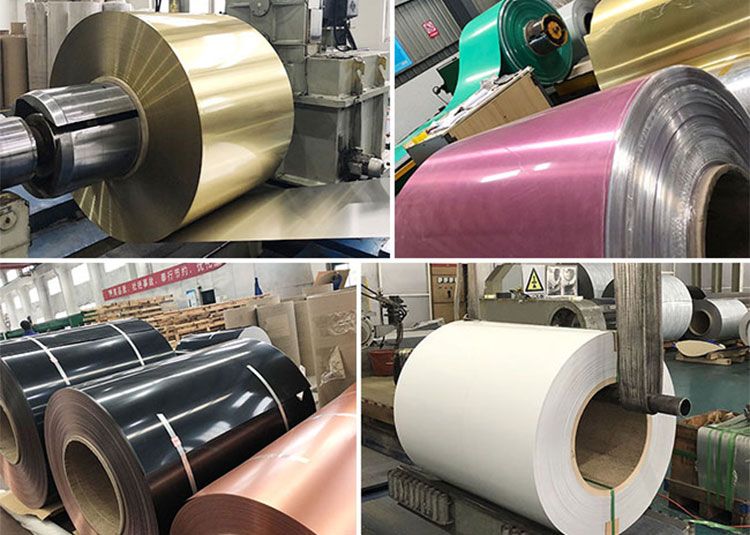

Color coated aluminum coil is an essential material extensively used across architectural, automotive, and household appliance industries for its excellent durability and aesthetic appeal. Among the various alloys available, 1060, 1100, 3003, and 3105 color coated aluminum coils is know due to their distinct properties and versatility.

These four classic alloys are predominantly used in color coated aluminum applications because of their excellent corrosion resistance, formability, and surface quality which are critical for coating performance. The coating process commonly involves PVDF or polyester coatings to provide a glossy or matte finish with strong weathering resistance.

Each alloy caters to specific uses based on their chemical composition and tempering characteristics:

- 1060 and 1100: High purity aluminum with excellent corrosion resistance and formability.

- 3003: Aluminum-manganese alloy with enhanced strength and corrosion resistance.

- 3105: Commonly utilized Gl laminated with slight manganese additions for improved mechanical properties and corrosion resistance.

Functions and Benefits

- Superior corrosion resistance: Suitable for external and humid environments.

- Excellent paint adhesion: Provides a premium finish for aesthetics and durability.

- Good formability: Ideal for deep drawing, bending, and rolling processes.

- Lightweight yet strong: Saves transportation costs, provides ease of installation.

- UV resistance and weather durability: Ensures color longevity under harsh sunlight.

These qualities make color coated aluminum coils ideal for facades, roofing, ceilings, gutters, and household appliances.

Common Applications

| Industry | Application Examples |

|---|---|

| Construction & Architecture | Exterior wall paneling, roofing sheets, ceiling tiles |

| Automotive | Decorative trims, paneling parts |

| Appliances | Refrigerators, air conditioner housings |

| Signage & Advertising | Signboards, display materials |

| Furniture | Lightweight decorative panels, shelving |

Alloy Chemical Composition

the chemical properties aids in anticipating the alloy performance regarding strength, ductility, and corrosion resistance.

| Element | 1060 (%) | 1100 (%) | 3003 (%) | 3105 (%) |

|---|---|---|---|---|

| Aluminum (Al) | 99.6 min | 99.0 min | 96.8 min | 97.0 min |

| Copper (Cu) | ≤0.05 | ≤0.05 | ≤0.10 | ≤0.08 |

| Iron (Fe) | ≤0.35 | ≤0.95 | ≤0.70 | ≤0.30 |

| Manganese (Mn) | ≤0.03 | ≤0.05 | 1.0-1.5 | 0.3-0.7 |

| Silicon (Si) | ≤0.03 | ≤0.95 | ≤0.60 | ≤0.20 |

| Zinc (Zn) | ≤0.03 | ≤0.03 | ≤0.10 | ≤0.10 |

| Others (each) | ≤0.03 | ≤0.05 | ≤0.05 | ≤0.05 |

| Others (total) | ≤0.10 | ≤0.15 | ≤0.15 | ≤0.15 |

Temper and Mechanical Specifications

| Alloy | Common Tempers | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 1060 | H14, H16 | 60–90 | 30–50 | 18–30 |

| 1100 | H14, H16 | 70–110 | 35–60 | 15–25 |

| 3003 | H14, H16, H24 | 110–145 | 80–110 | 10–12 |

| 3105 | H14, H24 | 110–140 | 70–110 | 10–15 |

- H14 (quarter hard) is frequently used in color coated coil making due to its excellent balance of formability and mechanical efficacy.

- H16/H24 indicate higher strength but reduced formability relevant for parts requiring added mechanical endurance.

Dimensional and Technical Parameters

| Parameter | Typical Value |

|---|---|

| Thickness | 0.15mm – 1.2mm |

| Width | 100mm – 1650mm |

| Coil Weight | 3 – 8 tons |

| Surface Treatment | Chromate, Passivation Layers |

| Coating System | PVDF / FEVE / Polyester / Silicon Modified |

| Coating Thickness | 20-30 µm (top coat), 5-7 µm (back coat) |

| Surface Quality | Smooth / Stucco Grain / Embossed |

Implementation Standards

| Standard | Description |

|---|---|

| GB 5237 | Technical Delivery Conditions |

| ASTM B209 | Aluminum and Aluminum-Alloy Sheet and Plate |

| EN 485 | Aluminum and Aluminum Alloys - Sheet, Strip, and Plate |

| JIS H4000 | Japan industrial standards for Aluminum |

| AAMA 2605 | Specification for High-Performance Organic Coatings for Aluminum |

Adhering to these stringent standards ensures product reliability for demanding applications and provides customers with tailored aluminum coil solutions.