3003 Embossed Aluminium Plate: A Practical Guide from the User’s Side

When engineers, buyers, and contractors talk about embossed aluminium, the conversation often jumps straight into surface patterns and prices. But if you look closer at 3003 embossed aluminium plate, you’ll notice something important: this is not just a “textured metal sheet.” It’s a carefully balanced material designed for long-term performance in real-world environments where moisture, movement, and wear are part of everyday life.

What 3003 Alloy Really Is – Beyond the Name

The “3003” in 3003 embossed aluminium plate refers to the alloy designation in the 3xxx series, which is aluminium-manganese based. That manganese addition is the quiet hero here. It increases strength over pure aluminium (such as 1050 or 1100) without damaging formability or corrosion resistance.

In essence, 3003 offers:

- Moderate strength compared with pure aluminium

- Excellent resistance to corrosion in normal atmospheres and many mild industrial environments

- Very good workability and deep-drawing performance

- Good surface finish, ideal for embossing

This combination is exactly why 3003 is so often chosen for embossed plates used in HVAC, insulation cladding, cold storage, food equipment, vehicle interiors, decorative panels, and protective coverings.

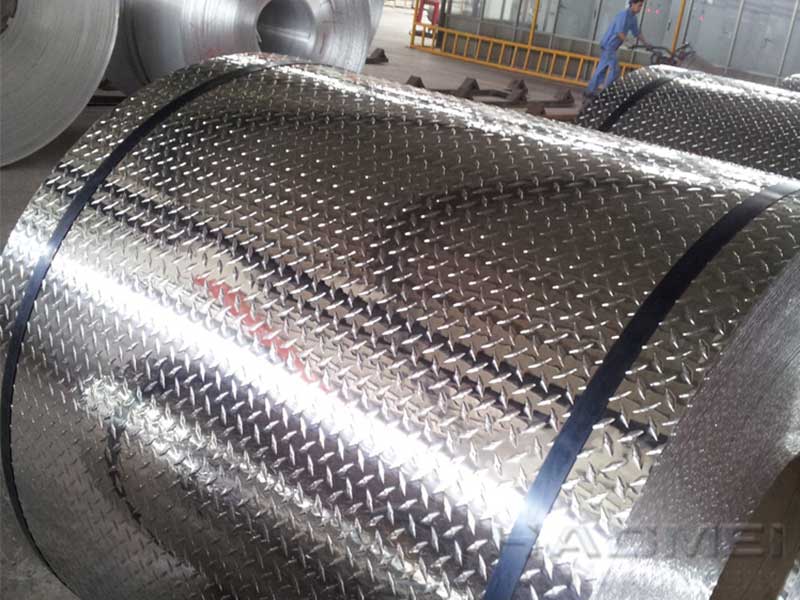

Embossing: More Than Just a Pattern

Embossing transforms flat 3003 aluminium into a functional surface. The rolling process presses a raised or recessed pattern into the material. This does three jobs:

- Improves slip resistance – useful for walkways, vehicle floors, ramps, or any area where moisture can create a hazard

- Enhances rigidity – even thin sheets feel stiffer once embossed, helping reduce material thickness and weight

- Adds visual texture – useful for architectural panels, interior finishes, and protective cladding that must still look refined

Common patterns for 3003 embossed aluminium include:

- Stucco embossed: irregular, gently textured surface that diffuses light and hides fingerprints, minor scratches, or small dents

- Diamond or five-bar tread: more aggressive, raised pattern designed mainly for grip on floors, stairs, and loading areas

- Orange peel or pebble: decorative surfaces used in refrigeration, appliance casings, and decorative interior elements

When you choose 3003 as the base alloy, you’re effectively matching a functional texture with a stable, corrosion-resistant, easily formable substrate.

Typical Parameters: Thickness, Width, and Tolerances

From a buyer’s perspective, 3003 embossed aluminium plate must fit into an existing system: pipes, ducts, wall spacing, frame structures, or machine housings. That makes basic dimensional parameters crucial.

Common thickness range:

- About 0.20 mm to 6.0 mm for embossed sheet and plate

- Thin gauges (0.2–1.0 mm) are often used for cladding, duct wrapping, insulation jacketing, and refrigeration panels

- Medium gauges (1.0–3.0 mm) for interior panels, door skins, equipment covers, and non-structural partitions

- Thicker plates (3.0–6.0 mm and above) for light-duty flooring, protective guards, and mechanical housings

Typical widths and lengths:

- Widths up to around 1600 mm are common, sometimes wider depending on mill capabilities

- Lengths are available in standard sheets (often 2000, 2440, 2500, or 3000 mm) or as coils for continuous processing

Tolerances generally follow standards such as EN, ASTM, or GB for thickness, flatness, and width. Embossing will alter the apparent thickness slightly because of the raised pattern, but the base metal thickness is controlled before embossing.

Alloy Temper: Why H14 and H24 Keep Appearing

3003 embossed aluminium plate does not come in a single “hardness.” The temper designation tells you how the material was processed and how it will behave during forming or in service.

For 3003, common tempers used in embossed sheet include:

- O (annealed): Very soft, excellent for deep drawing and severe forming, but low strength. Used when extreme formability is needed before embossing or for complex shapes.

- H12 / H14: Strain-hardened to a medium strength level. H14 is one of the most widely used tempers for embossed 3003. It balances enough strength for cladding and panels with good formability for bending, rolling, and flanging.

- H16 / H18: Higher strength through more cold work, reduced ductility. Used when stiffness and surface robustness outweigh the need for heavy forming.

- H22 / H24: Strain-hardened and then partially annealed. H24 is another very popular choice for sheet and plate that must be formed yet remain dimensionally stable.

In practice, many customers choose 3003 H14 or H24 embossed plate for insulation jacketing, building decoration, and refrigeration panels because these tempers can be easily cut, bent, and roll-formed on site without cracking.

Chemical Composition: What’s Inside 3003

A simplified, typical chemical composition range for 3003 alloy is:

| Element | Typical Range (%) |

|---|---|

| Aluminium (Al) | Balance |

| Manganese (Mn) | 1.0 – 1.5 |

| Copper (Cu) | 0.05 – 0.20 |

| Iron (Fe) | ≤ 0.70 |

| Silicon (Si) | ≤ 0.60 |

| Zinc (Zn) | ≤ 0.10 |

| Other (each) | ≤ 0.05 |

| Other (total) | ≤ 0.15 |

From a practical standpoint:

- Manganese is the main alloying element providing strength and improved resistance to certain forms of corrosion.

- Copper is present in small amounts, giving a slight strength increase while keeping corrosion resistance high.

- Iron and silicon are controlled impurities that can influence workability and surface finish.

This composition helps explain why 3003 is favored for environments like kitchens, food equipment housings, insulation cladding, and building envelopes, where condensation, humidity, and temperature changes are common, but strong acids or alkalis are not.

Mechanical Properties: What the Numbers Mean in Use

Typical mechanical properties for 3003 embossed aluminium plate (base sheet, before embossing) in common tempers are approximately:

| Temper | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) |

|---|---|---|---|

| O | 95 – 130 | ≥ 35 | ≥ 20 |

| H14 | 145 – 185 | ≥ 115 | ≥ 5–8 |

| H24 | 130 – 180 | ≥ 115 | ≥ 5–10 |

Actual values vary with thickness and production route, but these ranges help with design decisions.

For a user, this means:

- In H14 or H24, 3003 embossed plate is strong enough for cladding, panels, and non-structural protective surfaces that occasionally experience impact or handling.

- It can be sheared, punched, folded, and roll-formed without special tooling or preheating, as long as forming radii and process conditions are reasonable.

- The embossed pattern adds a “pseudo-stiffness” effect, reducing visible oil-canning and making panels feel more rigid.

Implementation Standards and Quality References

Suppliers of 3003 embossed aluminium plate usually align with international or regional standards for flat-rolled aluminium products. Depending on the market, you may reference:

- ASTM B209 for aluminium and aluminium-alloy sheet and plate

- EN 485 / EN 573 series for wrought aluminium products and chemical composition

- GB/T standards for the Chinese market

Conformity to these standards ensures that the material’s composition, mechanical properties, tolerances, and test methods are controlled. For project owners and contractors, requesting standard-compliant 3003 embossed sheet reduces risk and helps maintain consistent performance across different batches or suppliers.

Where 3003 Embossed Plate Excels in the Real World

From the user’s perspective, the value of 3003 embossed aluminium plate is most visible in a few application areas:

- Thermal and acoustic insulation cladding: Around pipes, tanks, ducts, and equipment, stucco embossed 3003 provides a tough, corrosion-resistant shield that resists weather and mechanical damage while hiding minor imperfections.

- Refrigeration and cold storage: Panels and liners benefit from the corrosion resistance, clean appearance, and textured surface that reduces glare and masks dents.

- Transport and vehicle interiors: Lightweight, patterned surfaces for walls, ceilings, and light-duty flooring help reduce weight while maintaining a durable, easy-to-clean finish.

- Building decoration: Facades, ceilings, and interior panels use embossed 3003 when they need a combination of modern metallic appearance, texture, and resistance to moisture and staining.

In all these cases, the material is not just chosen for its appearance; it’s chosen because it performs reliably under daily thermal cycling, cleaning, vibration, and handling.

Choosing the Right 3003 Embossed Aluminium Plate for Your Project

When selecting 3003 embossed aluminium plate, it helps to think in three directions at once:

- Function: Is slip resistance, rigidity, or purely decorative effect most important? This steers you toward specific embossing patterns.

- Forming: Will the material be deeply drawn, sharply bent, or gently curved? This influences the choice of temper, typically O, H14, or H24.

- Environment: Is it a marine, industrial, food-processing, or general building environment? 3003 is ideal for mild to moderately corrosive settings but should be evaluated against stronger chemicals if present.

By aligning pattern, thickness, temper, and standard with your real operating conditions, 3003 embossed aluminium plate becomes not just a sheet of metal, but a tailored surface solution that balances aesthetics, durability, and cost.