Anodized aluminum sheet 1100 1060 2024 3003 6061 8011

10/06 2025 Leo

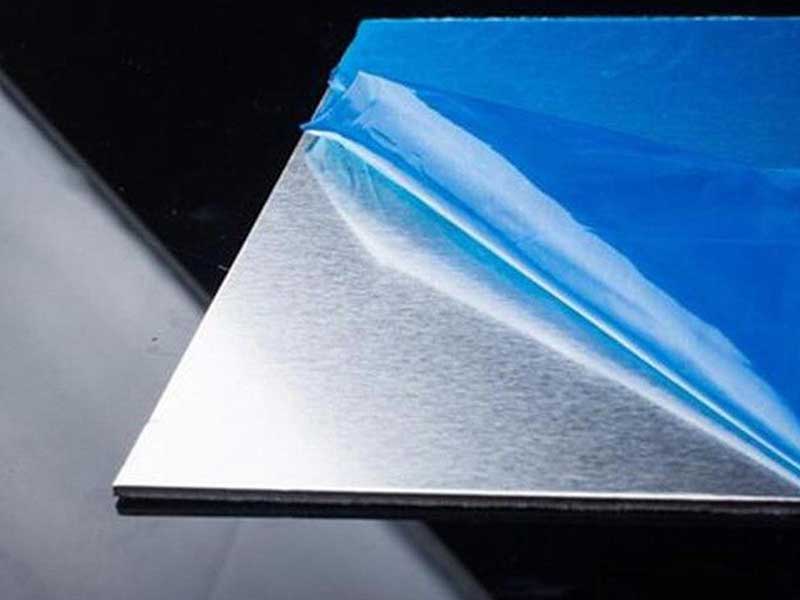

Anodized aluminum sheets are aluminum alloy sheets that have been electrochemically treated to create a durable, corrosion-resistant oxide layer on the surface. This process significantly enhances the material's longevity, surface hardness, aesthetic appeal, and corrosion resistance while retaining the inherent lightweight and versatile qualities of aluminum.

| Alloy | Series | Typical Use | Characteristics |

|---|

| 1100 | 1xxx | Decorative and architectural | Excellent corrosion resistance, high purity (≥99%), low strength |

| 1060 | 1xxx | Electrical and chemical equipment | Very good formability and corrosion resistance, >99.6% aluminum content |

| 2024 | 2xxx | Aerospace, military | High strength and fatigue resistance, not ideal for high corrosion environments |

| 3003 | 3xxx | Roofing, siding, cooking utensils | Good corrosion resistance moderate strength, good workability |

| 6061 | 6xxx | Structural and transportation | Well-balanced mechanical properties, good corrosion resistance |

| 8011 | 8xxx | Packaging and household products | Good workability with corrosion resistance against atmospheric effects |

Chemical Composition of Alloys (wt.%)

The composition detailed below is elemental specifications for the listed alloys:

| Alloy | Si | Fe | Cu | Mn | Mg | Zn | Cr | Ti | Al |

|---|

| 1100 | ≤0.95 | ≤0.95 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.05 | 0.05 | 0.03 | Balance ≥99.0% |

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | 0.03 | 0.03 | 0.03 | Balance ≥99.6% |

| 2024 | 0.5 | 0.5 | 3.8-4.9 | 0.3-0.9 | 1.2-1.8 | ≤0.25 | 0.1 | 0.15 | Balance |

| 3003 | 0.6 | 0.7 | 0.05 | 1.0-1.5 | 0.1 | 0.1 | 0.05 | 0.05 | Balance |

| 6061 | 0.4 | 0.7 | 0.15 | 0.15 | 0.8-1.2 | 0.25 | 0.04-0.35 | 0.15 | Balance |

| 8011 | 0.6 | 1.0 | 0.1 | 0.05 | <0.1 | 0.85 | 0.05 | 0.03 | Balance |

Mechanical Properties of Anodized Aluminum Sheets

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Hardness (HV) | Density (g/cm³) | Thermal Conductivity (W/m·K) |

|---|

| 1100 | 90 | 35 | 35-50 | 35 | 2.70 | 220 |

| 1060 | 70-90 | 34-48 | 35-42 | 30-40 | 2.70 | 220 |

| 2024 | 420-480 | 280-320 | 10-20 | 120 | 2.78 | 121 |

| 3003 | 130-180 | 110-140 | 18-28 | 65 | 2.73 | 160 |

| 6061 | 270-310 | 240-275 | 12-20 | 95 | 2.70 | 167 |

| 8011 | 120-140 | 90-110 | 22-28 | 55 | 2.70 | 170 |

Advantages of Anodized Aluminum Sheets

- Enhanced Corrosion Resistance: Exceptional resistance to atmospheric chemicals and saltwater.

- Improved Surface Hardness: Anodic oxide is 3-5 times harder than raw aluminum, protecting against scratches and wear.

- Aesthetic Versatility: Available with a matte, glossy, or colored finish for architectural friendliness.

- Thermal and Electrical Insulation: Anodized layer acts as an electrical insulator and improves thermal emissivity.

- Environmental Compatibility: Non-toxic surface suitable for food contact and medical applications.

- Easy Maintenance: Smooth anodized surfaces are easier to clean and resist stains.

Common Applications of Anodized Aluminum Sheets by Alloy

| Alloy | Typical Applications |

|---|

| 1100 | Decorative panels, signage, lighting reflectors, electronics casing |

| 1060 | Chemical equipment, packaging foil, electrical cables shield |

| 2024 | Aerospace components, military vehicle armor, high-strength structural parts |

| 3003 | Roofing sheets, gutters, cookware, storage tanks |

| 6061 | Structural components, automotive panels, frames, marine parts |

| 8011 | Roof and wall panels, household packaging foil, laminated tubing |

| Parameter | Typical Value |

|---|

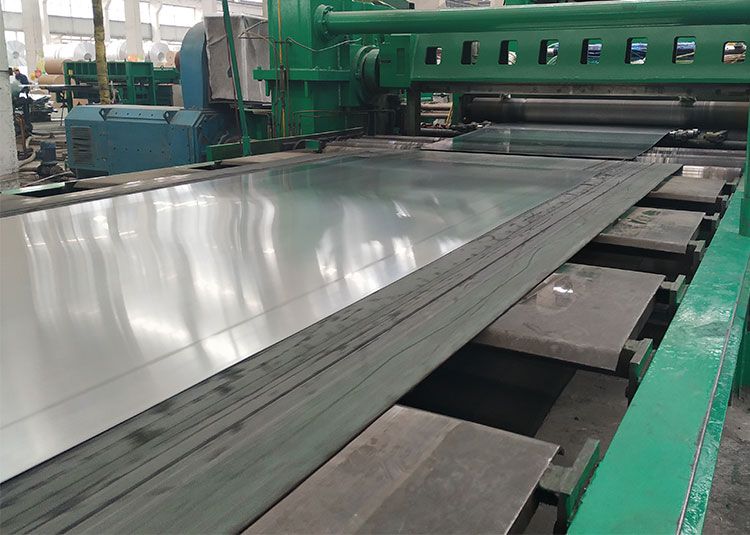

| Thickness Range | 0.2 mm to 10 mm |

| Anodized Layer Thickness | 5 – 25 microns (standard) up to 100 microns (thicker coatings available) |

| Tensile Strength Range | 70 MPa (soft alloys) to 480 MPa (high-strength alloys) |

| Corrosion Resistance | Excellent including salty, acidic, and alkaline environments |

| Surface Finish | Bright, matte, brushed, colored (dyes post-anodization) |

| Available Forms | Sheets, coils, plates |

1060

1100

2024

3003

6061

8011

https://www.aluminum-sheet-metal.com/a/anodized-aluminum-sheet-1100-1060-2024-3003-6061-8011.html

Related Products

Related Blog

4×8 Aluminum Sheet

4 x 8 Aluminum sheet is the standard dimension which widely used in construction. We can produce 4 x 8 Aluminum sheet with alloy 1100, 1050,1060,1200, 3003, 3105, 5052, 5083,5005,6061,6063,etc.The thickness range from 0.3mm to 200mm.