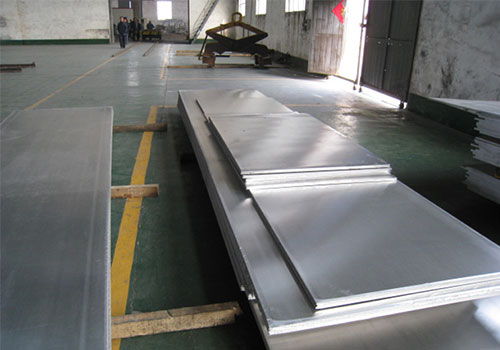

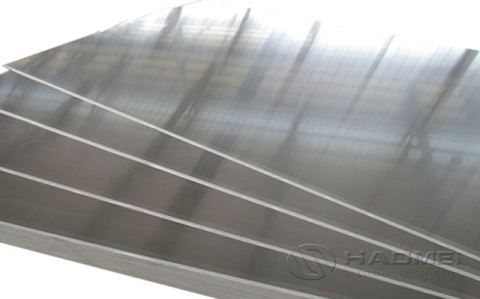

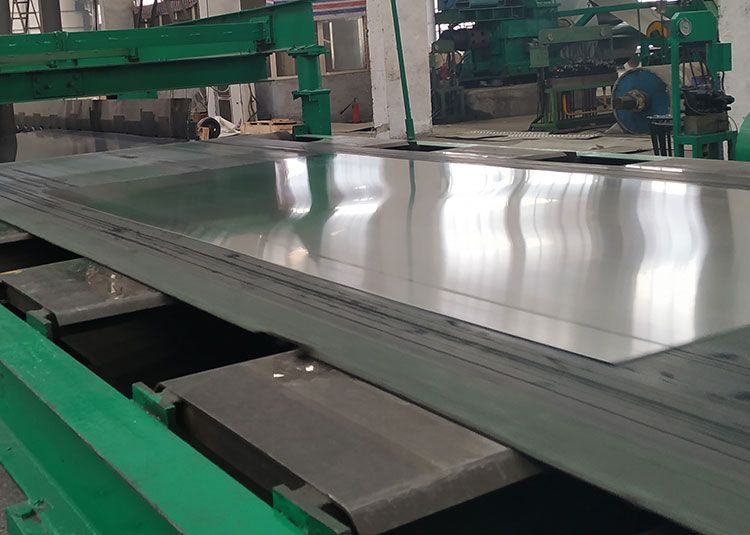

The 3003, 3004, and 3105 aluminum sheets are versatile and high-performance aluminum products, well-regarded in various industrial and commercial applications. With thickness options of 2mm and 8mm, these aluminum sheets cater to a broad range of needs, from structural support to decorative applications.

Features

- Alloy Composition: Made from 3003, 3004, and 3105 aluminum alloys, this sheet offers excellent workability and corrosion resistance.

- Thickness Variance: Available in both 2mm and 8mm thickness, these sheets fulfill diverse application requirements.

- Weldability: The aluminum sheet allows for easy welding processes due to its favorable mechanical properties.

- Formability: With excellent flexibility, these sheets can be easily bent or shaped into different forms.

- Finish Options: Available in various finishes, including mill, brushed, or anodized, offering aesthetic flexibility for designs.

Applications

- Refrigeration and air conditioning housings

- Automotive body panels

- Cooking utensils and kitchen fixtures

- Chemical storage tanks

- Building and construction industry components

- Decorative applications in architecture

Technical Specifications

The following table summarizes the technical specifications of the 3003, 3004, and 3105 aluminum sheets:

| Property | 3003 | 3004 | 3105 |

|---|---|---|---|

| Alloy Type | 3003 | 3004 | 3105 |

| Thickness | 2mm / 8mm | 2mm / 8mm | 2mm / 8mm |

| Density | 2.73 g/cm³ | 2.73 g/cm³ | 2.73 g/cm³ |

| Yield Strength | 124 MPa (18,000 psi) | 180 MPa (26,000 psi) | 172 MPa (25,000 psi) |

| Tensile Strength | 210 MPa (30,000 psi) | 270 MPa (39,000 psi) | 210 MPa (30,000 psi) |

| Elongation | 25% (minimum) | 15% (minimum) | 16% (minimum) |

| Thermal Conductivity | 160 W/m·K | 156 W/m·K | 174 W/m·K Publication of datasheets |

| Melting Point | 645°C (1193°F) | 650°C (1202°F) | 660°C (1220°F) |

Chemical Properties

The chemical composition of the 3003, 3004, and 3105 aluminum sheets can vary slightly, summarizing the major alloying elements:

| Element | % Content (3003) | % Content (3004) | % Content (3105) |

|---|---|---|---|

| Aluminum (Al) | Bal. | Bal. | Bal. |

| Copper (Cu) | 0.05 - 0.20% | 0.08 - 0.20% | < 0.0.50% |

| Manganese (Mn) | 1.0 - 1.5% | 1.0 - 1.5% | 0.03 - 0.2% |

| Magnesium (Mg) | 0.0 - 0.10% | < 0.30% | 0.40 - 0.9% |

| Silicon (Si) | 0.0 - 0.30% | < 0.3% | < 0.0.50% |

| Iron (Fe) | 0.0 - 0.70% | 0.0 - 0.7% | < 0.15% |

| Zinc (Zn) | < 0.10% | < 0.10% | < 0.0.10% |

The choice of 3003, 3004, and 3105 aluminum sheets in thicknesses of 2mm and 8mm makes these alloys valuable for various applications ranging from construction to the food industry due to their excellent corrosion resistance, formability, and weldability. Robust mechanical properties combined with lightness and distinct aesthetic qualities solidify these aluminum sheets as a top choice.

Whether you need functional, high-strength applications or visually appealing designs, these aluminum sheets make them feasible. The versatility, practicality, and performance of 3003, 3004, and 3105 provide effective solutions suited to current industry demands.

By embracing these qualities, you can ensure that you are making an informed, optimal decision for your aluminum material needs.