Aluminum foil has carved a significant niche for itself across various industries, especially in the realms of packaging and electronics. Among its unique applications, the use of aluminum foil jumbo rolls for cable wrapping and shielding stands out due to its effective electromagnetic interference (EMI) protection.

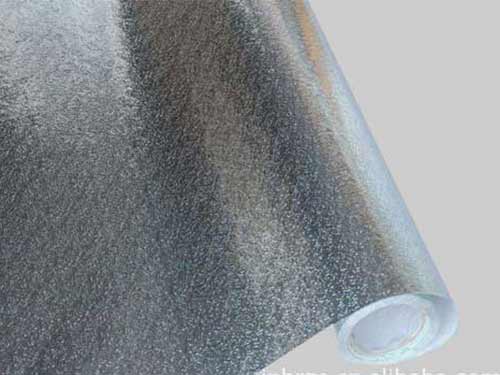

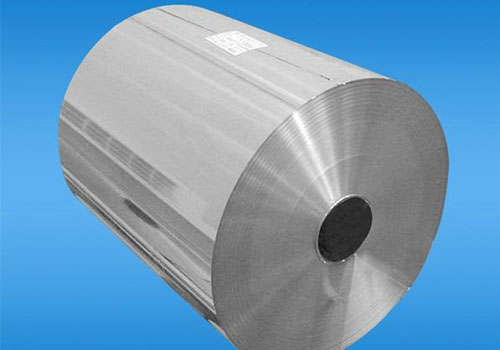

Aluminum Foil Jumbo Rolls

Aluminum foil jumbo rolls are large-width aluminum sheets, typically produced in thickness variations between 6 to 50 micrometers. Owing to their excellent malleability and conductivity, these rolls are becoming the preferred material for cable manufacturers, focusing on both electrical and physical protection.

Parameters of Aluminum Foil Jumbo Rolls

The efficacy of aluminum foil as a wrapping material can be evaluated by considering several technical parameters, as enumerated below:

| Parameter | Description |

|---|---|

| Thickness (mm) | Typically between 0.006 to 0.050 mm |

| Alloy Series | 1xxx, 3xxx, and 8xxx series are most common |

| Temper | Annealed (H18, O) or hard temper for structural stability |

| Chemical Properties | High corrosion resistance, high thermal conductivity |

| Roll Width | Standard sizes range from 300 to 1500 mm |

Alloy Tempering and Standards

The temper grades significantly affect the mechanical properties and, thus, the ultimate performance. They generally include:

- O Temper: Annealed state with good ductility, favorable for processes requiring bending or forming.

- H18 Temper: Hard state instructed via cold rolling, providing higher tensile strength at lower formability, beneficial for shielding applications.

Implementation standards are critical in ensuring not only the shielding capability but also regulated safety aspects. The IEC standards (International Electrotechnical Commission) often apply in measuring these performance parameters.

Unique Advantages of Aluminum Foil in Cable Wrapping and Shielding Applications

When it comes to robust electromagnetic shielding, aluminum foil excels due to the following standout properties:

Electromagnetic Interference (EMI) Shielding: Aluminum’s electrical conductivity allows it to lead away undesirable frequencies, thus protecting the signal integrity of sensitive cables. The unique physical design of various foil layers in aluminum jumbo rolls augments this capability.

Weight vs. Strength Ratio: Lightweight yet incredibly strong, aluminum cables wrapped in foil can withstand environmental and mechanical stresses while simultaneously offering substantial protection against EMI.

Thermal Considerations: The excellent thermal conductivity of aluminum foil ensures that cables do not overheat. Foil's unique conductive properties espouse an active dissipation of heat created during high-powered operations.

Corrosion Resistance: Standard rolled aluminum naturally develops an oxide layer, granting long-lasting durability and resistance against wear-an essential aspect for prolonged efficacy in hostile environments.

Selecting the Right Aluminum Foil Jumbo Roll

Choosing the appropriate aluminum jumbo roll is crucial for optimal performance. Manufacturers must consider factors such as foil thickness, alloy series, and suitability for specific wrapping duties. Guidelines may include performance-grade requirements that align with electrostatic regulations. Employing the right alloy tempers can improve tensile strength and enhance workability in application excellence.